Upgrade the game settings: The ultimate 3D printed Xbox controller stand

Is your Xbox controller constantly tangled around the ropes, messing up the table or sliding off the surface? If you’re passionate about a clean, organized gaming station, a custom 3D printed controller rack is not only an accessory, but a game-changer. Forget the universal plastic holder; imagine a design stand Exactly For your controller model, reflect your personal style and last forever. This is the power that can be accessed through modern additive manufacturing. In this dive into the world of custom gaming equipment, we will explore how 3D printing can transform simple brackets into declaring works and functional necessities.

The rise of ergonomics in personalized gaming

The development of game settings goes beyond functionality. They are an extension of our personality and shelter for immersiveness. Despite the presence of mass-produced shelves, they are often lacking. They may sway, scratch the effect of your controller, only for specific models, or just look uninspired. 3D printing undermines these limitations. It enables gamers and designers to create suitable solutions Perfect. Whether your preference is the minimalist dock of the latest Xbox wireless controller, the multi-noble of the entire series or the futuristic-themed dock, it complements your console aesthetics, but the possibilities are only bound by your imagination. This level of personalization eliminates "Good enough" And hug "Perfect for me."

Design your dream standpoint: Functions fit in form

The journey begins with design, and this is where 3D printing really shines. The main considerations include:

- Precision fit: The bracket must firmly shake your controller without forcing it in or leaving too much clearance that causes slip. Leverage accurate 3D scans or carefully crafted CAD models to ensure the grips are resting naturally and are perfectly aligned for easy docking/recharge.

- Functional layer: Is it purely for display? Do you need an integrated cable management channel? Should it include a wireless charging coil (needs a careful material selection)? What about the storage of headphones or spare battery? These functional additions turn passive holders into active parts of the gaming ecosystem.

- Aesthetic talent: This is your chance to customize. Design elements that can be directly integrated into the structure, such as logos, gamer tags, game-inspired patterns or geometric patterns. A weighted base can be engraved for visual interest, or a transparent section can be used to display internal components if needed.

- Stability and durability: The bracket must remain rock solid, especially during controller placement/removal. Basic design (broad footprint, strategic weighting), material selection and structural engineering (internal ribs, wall thickness optimization) are crucial.

Online repositories such as Thingiverse or Printables offer many free designs, but use software like Fusion 360, Tinkercad, or Blender to create yourself or modify existing designs to unlock true personalization.

Material Problems: Building Performance and Style

Choosing the right material is crucial to strength, aesthetics, and longevity. Unlike enthusiast FDM printers that use melted plastic filaments, professional-grade metal 3D printing unlocks superior features and is ideal for controller stands (such as controller stands). Here is a comparison of options offered by services like Greatlime:

- Nylon (PA11/PA12-SLS): Excellent toughness, good chemical resistance and flexibility. Perfect for complex geometry and durable, lightweight stands. Can be dyed or painted. Ideal design Ideal design.

- Aluminum alloy (such as Alsi10mg -SLM): Provides excellent stiffness to weight ratio, high temperature conductivity (if incorporated into a charger (such as a charger) and impressive corrosion resistance. Provides a quality metal feel and look. Perfect for weighted bases, requiring maximum stability and a smooth industrial appearance.

- Stainless steel (e.g., 316L -SLM): The pinnacle of durability and corrosion resistance. Provides a lot of weight for ultimate stability, high strength and unique professional metal finishes (polishing, brushes, etc.). The ideal choice for minimalist design is key, or the key to high humidity environments.

- Titanium alloys (such as Ti6al4v -SLM): Unrivaled strength to weight ratio and biocompatibility. Give a super high-end, lightweight and exceptionally powerful position. Best design for the minimum weight of priority design without sacrificing integrity.

Great Advantages: Accuracy from Design to Complete

Imagine achieving this meticulous design vision with uncompromising quality. This is where to work with professional rapid prototyping manufacturers Great Become essential. We are not only printers; we are solutions providers for the high-precision part of the feature:

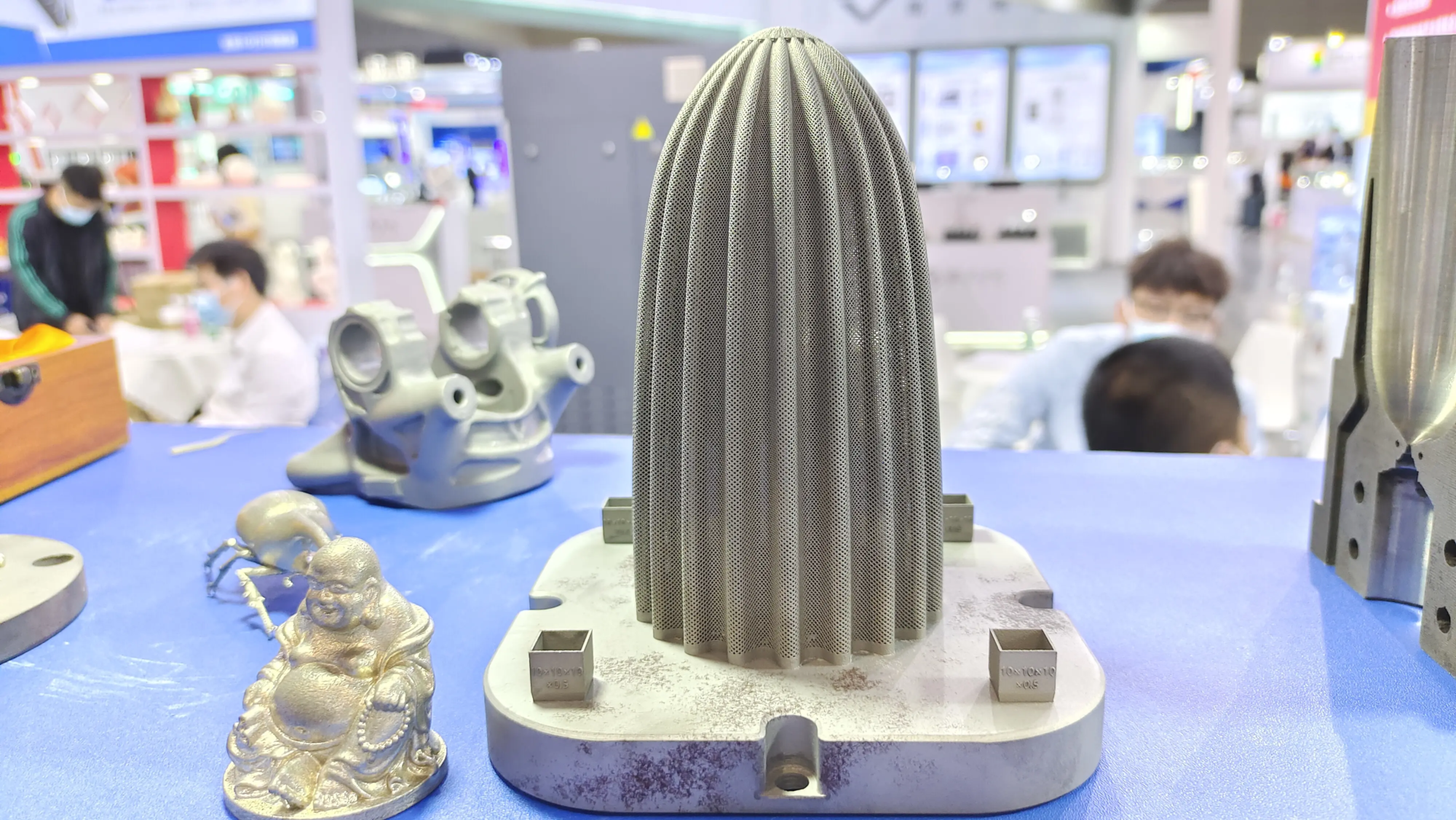

- Advanced SLM technology: We utilize state-of-the-art selective laser melting (SLM) metal 3D printers. SLM uses powerful laser fused fine metal powder layers to produce parts with near-density density, excellent mechanical properties and complex detail accuracy, far exceeding the amateur FDM method. This ensures that your stall is perfectly suited and can withstand daily use indefinitely.

- Complexity expertise: We thrive in challenging design. Complex lattice that reduces weight, integrated cable ducts, custom textures – our technical and engineering expertise makes it possible. We identify potential printability or structural issues early and provide DFM (designed for manufacturability) feedback.

- Unrivaled surface perfection: The original gold parts of the printer need to be refined. Greglight provides a comprehensive One-stop post-processing kit:

- Support removal: Accurately remove temporary support structures.

- Processing: CNC milling/drilling for critical tolerances or threads.

- Surface finish: Options range from bead blasting (matte texture) to grinding to precision polishing (mirror gloss), brushing, tumbling and vibrating finishes.

- Heat treatment: Anneale or age to relieve stress and achieve the desired material properties.

- Plating/Paint: Anodized (aluminum and protective) or electroplating (e.g. nickel) enhances aesthetics and corrosion.

- Quick and customized solutions: Need to be fast? We focus on fast turnaround without sacrificing quality. Most metal materials and finishes can be quickly customized and processed to meet a pressing deadline. We work closely with you to select the ideal materials and complete the combination for your stand function and aesthetic vision.

- Scalability: Whether you need a unique stall or a small batch for a game team or event, our process is effective and consistent.

Masterpiece from file to completion: Gremight Process

- Design and consultation: Submit your 3D model (STL, steps, etc.) and share your requirements (materials, completions, functional requirements). Our engineering team reviewed the design, optimized its printability and performance, and provided expert advice. Need design help? Ask about our design support services.

- Quotes and Orders: Received transparent quotes reflecting materials, completion options and quantities. Approve and start your project.

- Precision printing: In controlled inert atmosphere conditions, carefully print your bracket using SLM technology in selected metal alloys using SLM technology.

- Advanced post-processing: The original printed section is carefully selected after-treatment steps – support disassembly, any necessary machining and the finishing treatment of your choice – for the final look and feel. Strictly check the quality of parts.

- deliver goods: Your unique, high-quality 3D printed Xbox controller rack is ready to upgrade your gaming settings, carefully packaged and shipped directly to you.

in conclusion

The days of settlement are fragile, and the universal controller holder is over. 3D printing, especially at the level of expertise offered by companies like Greatlight, opens personalized, premium materials and perfect features for your Xbox accessories. Customized metal 3D printed stands go beyond practicality; it becomes a durable, elegant core that reflects your passion for gaming. It ensures that your controller is always stored securely, easily accessible and proudly displayed while adding sophisticated custom craftsmanship to your space. This is an investment in efficiency, aesthetics and pure player satisfaction. Stop letting your controller mess up your life – design and print the final solution.

FAQ: Your 3D Printed Xbox Controller Stand Questions Answered

-

How strong are metal 3D printed brackets compared to plastic?

- answer: Significantly stronger and more durable. Metal 3D printing, especially SLM, produces parts with excellent mechanical properties similar to (sometimes surpass) traditionally made metals. They resist impact, deformation and daily wear are far better than the common FDM or injection plastic racks, which are promisingly reliable services.

-

What file format do I need to provide?

- answer: We prefer common 3D file formats such as steps (for editable CAD data) or high resolution STL/OBJ (for printable grids). Make sure your model is varied (watertight) and error-free. Our team can assist with document preparation if needed.

-

Which metal material is best for my controller stand?

- answer: It depends on your priorities:

- Lightweight and tough: Nylon (SLS) or Titanium (SLM).

- Rigid, stable and thermally conductive (e.g., charging): Aluminum (SLM).

- Maximum durability, weight and quality finish: Stainless Steel (SLM).

Our experts will help you choose based on design complexity, weight required, stability requirements, aesthetics and budget.

- answer: It depends on your priorities:

-

Can you include wireless charging in the stands?

- answer: Yes! With careful design considerations (correct cavity size, material choice – non-ferromagnetic metal with best content of aluminum or titanium, guided by wires), wireless charging coils can be seamlessly integrated. Discuss this requirement during design consultation.

-

What post-processing finishes are available?

- answer: Greglight offers a wide range of:

- Mechanical: Bead blasting (smooth matte), polishing (high gloss), grinding/brushing (directional satin), tumbling/vibration (smooth, radiation edges).

- Chemical: Anodized (colored, protective layer – aluminum only).

- coating: Electroplating (e.g., chrome plating looks nickel, with increased hardness/corrosion).

Choices affect appearance and feel.

- answer: Greglight offers a wide range of:

-

How long does it take to create a custom stance?

- answer: Turnover varies according to design complexity, materials, selected finishes and order quantity, but Greatship specializes in Rapid prototyping. Simple designs can usually be shipped within a few days to a week. We prioritize quick quotes and clear communication about the timeline.

-

Is there only one stall for 3D printing cost-effective?

- answer: For highly customized, unique designs or designs that require specific advantages of robust metals, professional 3D printing is very cost-effective, especially compared to the cost of injection molding setup. You pay for custom designs, advanced material properties and unrivalled precision. While the cost of a single complex metal bracket does not exceed the basic plastic, the value of customization, durability and uniqueness is extraordinary.

- How to maintain a metal 3D printing rack?

- answer: Most metal finishes have very low maintenance. Just wipe it clean with a soft, dry or slightly damp cloth. Avoid using harsh chemicals or abrasive cleaners, especially on anodized or polished surfaces. Their inherent robustness protects them from most environmental factors.