Unleashing Convenience: The Ultimate Guide to 3D Printing Your Own Belt Clip

Everyday carry essentials like multi-tools, flashlights, tape measures, and even professional tools often require a reliable home. Instead of fumbling around in pockets or bags, DIY enthusiasts and professionals are harnessing the power of 3D printing to create a custom solution: the belt clip. This seemingly simple accessory brings incredible convenience and accessibility. Whether you’re a PLA printing enthusiast or an engineer in need of a sturdy metal clip, this guide will provide in-depth coverage of the design, printing, and perfection of your own 3D printed belt clip.

Why design a custom belt clip?

Ready-made belt clips exist, but they rarely fit perfectly. Custom 3D printing solves several problems:

- Perfect fit: Clips specifically designed for precise contours, dimensions and weight distribution your thing.

- Ergonomic design: Customized clip angle, retention and release mechanism for comfortable and intuitive one-handed operation.

- Unique requirements: Need a lanyard attachment point? Specific mounting holes? Integrated finger grip? Custom designs make this possible.

- Cost effectiveness: For unique shapes or low-volume needs, printing can be much cheaper than custom manufacturing through traditional methods.

- Beauty and personalization: Match colors, textures and styles to your outfit or personal preference.

Design Considerations: Beyond Hooks

A successful belt clip is more than just a curved piece of plastic/metal; This is a well-designed component:

- Holding power: This is critical. The clamp must hold the tool securely during movement but be easily removable. Factors affecting this:

- Clamp arm design: The length, thickness, curvature and elasticity of the arms determine the clamping force.

- Leverage points: Where the clamp pivots relative to the mounting point can significantly affect the force.

- Surface contact with each other: Make sure the clip has enough area to press against the belt or belt.

- Installation mechanism: How securely do the clips attach to your items? Common solutions:

- Screw hole: Strongest for heavier items or metal clips.

- Snap-on type: Plastic clamps are required to have precise dimensional tolerances.

- Sliding track/channel: Typically used for tools designed with clip integration in mind.

- Adhesive: Less permanent, use a strong adhesive such as epoxy for plastics (less ideal for sustained stress or metal).

- Belt Compatibility: Consider the typical thickness of the belt or belts being used. Include adequate clearance (usually >5mm).

- Material properties: Selected printing materials must There are enough:

- strength: Able to withstand repeated bending and clamping without breaking.

- Flexibility/elasticity: Safe springback is required after loading/unloading (especially important for plastic clamps).

- Printing direction: Strategically position your design on the print bed. Ideally, ply lines should be perpendicular to the major bending stresses for maximum strength. Avoid placing critical pivot points or thin sections parallel to the layer. Clamps with steep overhangs may require support.

Material Selection: Plastic Fabric vs. Industrial Metal

The best material depends largely on the needs of the application:

- Common Plastics (Hobbyist/Medium Duty):

- Polyethylene glycol: Excellent choice! Offers high strength, impact resistance, good layer adhesion and moderate flexibility. Has excellent UV and moisture resistance. Highly recommended.

- Nylon (PA): Very tough, flexible and durable. Excellent wear resistance. Will absorb moisture and needs to be actively dried before printing. High nozzle/bed temperatures are required.

- TPU/TPE (semi-flexible): Ideal for clamps that require extreme flexibility. create a softer "hold tightly" On the belt. Requires slower print speeds and careful calibration. May tire more quickly than PETG over time.

- People’s Liberation Army: Easy to print, but will become brittle over time. Easily breaks under repeated bending stress. Generally not recommended unless it’s a temporary or very low pressure clip.

- Engineering Plastics and Metals (Professional/Heavy Duty):

- ABS: It is stiff and has good impact resistance, but PETG for clamps generally performs better than PETG unless greater temperature stability is required.

- ASA: UV stabilized alternative to ABS with good outdoor durability.

- Polypropylene (PP): Highly flexible and chemical resistant, but difficult to print due to warping and low bed adhesion.

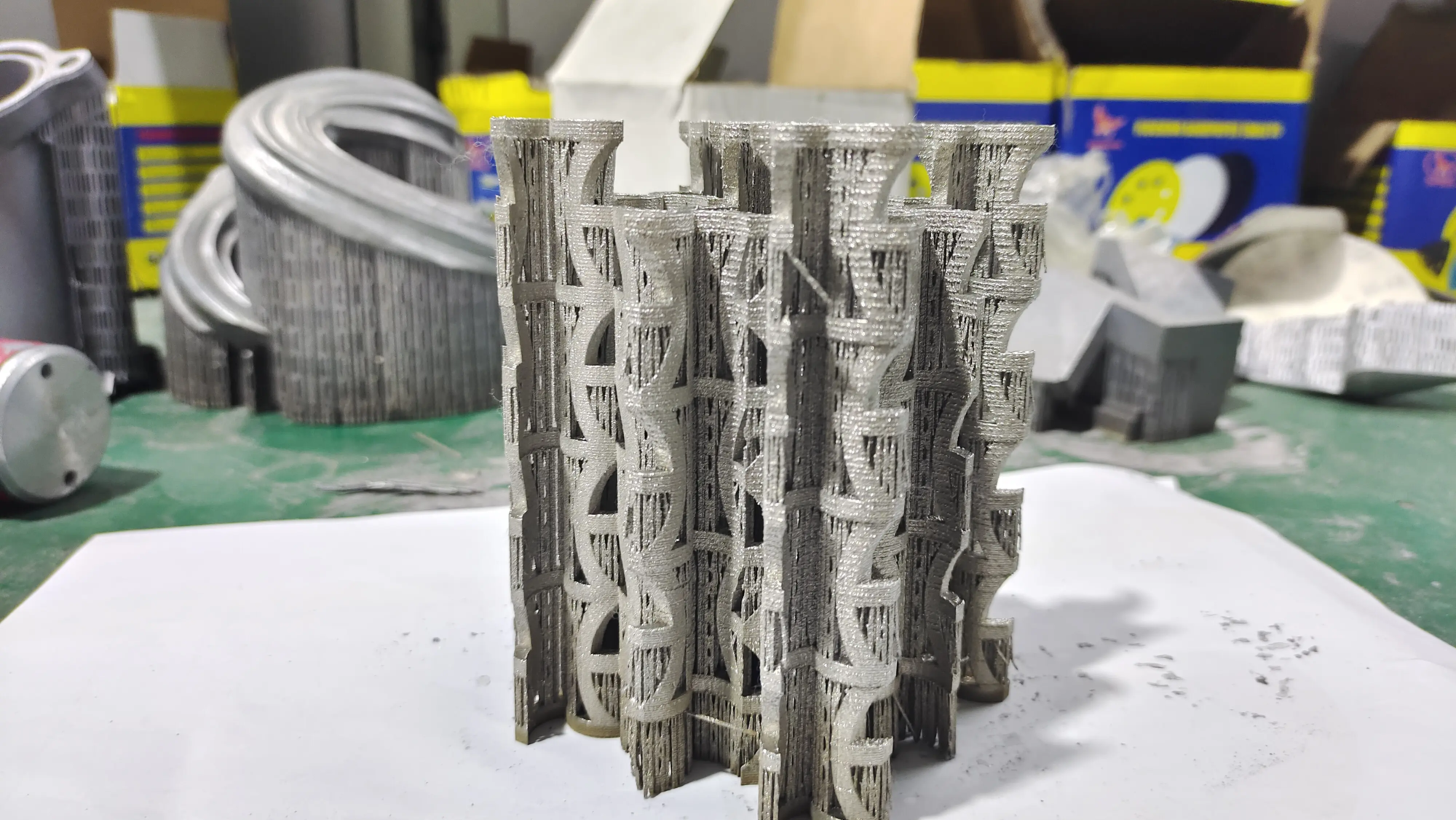

- Metal (SLM/DMLS): Ideal for mission-critical applications requiring maximum strength, durability, corrosion resistance or high temperature performance. Materials such as titanium (Ti6Al4V), stainless steel (316L, 17-4 PH), aluminum (AlSi10Mg) or cobalt-chromium alloys offer unparalleled robustness. These fully dense metal parts produced by selective laser melting require specialized industrial printers.

Optimize the printing process

Success depends on printing settings adjusted to your materials and designs:

- Wall thickness and filling: For structural integrity, prioritize perimeter/walls over infill. Aim for 4-6 girth and 30-50% infill (more dense for heavier items). A solid top/bottom layer is essential.

- Temperature and cooling: Strictly follow material-specific guidelines. Crucial: Make sure plastics such as PETG and PLA are sufficiently cooled to maintain dimensional accuracy and strength at the pivot. Overcooling ABS/ASA can cause warping.

- Print speed: slow down! Printing thicker perimeters and complex features too quickly will compromise layer adhesion and detail quality. Flexible filaments require particularly slow speeds.

- Support structure: Use supports for complex geometries. Optimized settings (e.g. support for interface spacing, patterns) for easier deletion. Tree supports are often great for clamps. Orient the print to minimize overhangs that require support.

Post-processing: Refining strength and smoothness

Raw printed parts often benefit from finishing:

- Remove supports: Carefully remove the supports using pliers, scissors, or flat shears. If necessary, adjust print settings (support for interface gaps, patterns) to aid removal.

- Polishing: Smooth rough edges, support scars or layer lines, starting with coarse grain (~120) and progressing to fine grain (~400-600). Wet sanding prevents clogging. Wear a mask!

- Annealing (think: plastic tempering): Significantly improves interlayer adhesion and heat resistance of materials such as PETG. Involves heating the finished print below the melting point in a controlled oven or water bath and then cooling it slowly.

- Metal finish: Metal SLM parts often require sandblasting to remove powder residue. Further processes such as CNC machining, polishing, electroplating or painting can improve aesthetics or performance.

- Paint/Coating (Plastic): Primers/paints designed specifically for plastics improve aesthetics. Clear coat adds UV protection.

Can I print my own metal clips?

While desktop metal 3D printing for functional clips is still emerging and expensive, specialist workshops still exist. For extremely durable, heat-resistant or industrial-grade belt clips, Metal Additive Manufacturing (SLM/DMLS) is the gold standard.

Conclusion: Empowerment through customization

3D printing has democratized the creation of functional hardware such as belt clips. By understanding design principles, material properties, printing techniques, and post-processing options, you can create clips that are superior to common alternatives. From flexible TPU trouser clips for ID badges to sturdy metal clips for heavy-duty tools, the possibilities are endless.

The process often starts with easy-to-use plastics like PETG—durable and printable on common machines. However, when durability needs skyrocket or environmental demands intensify (heat, chemicals, constant vibration), upgrade to professional manufacturing 3D printing metal clips via selective laser melting (SLM) become crucial. This is where expertise in advanced materials science and precision metal printing delivers unrivaled functionality and longevity.

FAQ: Answers to your belt clip printing questions

- Q: What is the easiest plastic filament to print a functional belt clip with?

one: polyethylene terephthalate Achieve optimal balance. It’s easier to print than nylon or flexible materials, is strong, is slightly flexible (essential for elasticity), and is resistant to moisture and UV degradation. For anything that requires long-lasting and repeated bending, avoid PLA.

- Q: How thick should the clamp arms be?

A: There is no one-size-fits-all answer; it depends heavily on the material, clamp width, and required retention. For PETG, start with a thickness of around 3-5 mm as a baseline for small clips. Mock/test prototypes are key! Before moving on to the design, thinner sections are printed on the prototype to test flexibility and strength.

- Q: How to prevent plastic belt clips from breaking?

one: Material selection: Use PETG, nylon or TPU. PLA and brittle ABS tend to fail. design: Avoid sharp corners (add rounded corners), orient the print correctly (perpendicular to the layer line of the stress), make sure there is sufficient thickness at the pivot/stress point. Print settings: Ensure proper layer adhesion (correct temperature, speed, no under-extrusion). Post-processing: PETG annealing can significantly improve toughness.

- Q: When should you consider using a metal 3D printed belt clip instead of a plastic belt clip?

Answer: Switch to metal if:

- Support heavy objects (always more than 0.5-1 kg).

- Exposed to extreme environments (high temperatures, chemical exposure sustained above PETG/nylon limits).

- Requires absolute maximum durability and resistance to fatigue (constant cycling/loosening).

- Flame retardant or electromagnetic interference shielding properties are required.

- Q: Why is post-processing important for belt clips?

one: Remove support marks: Ensures smooth movement of the belt/wearer. smooth: Improves aesthetics and prevents snagging on clothing. annealing: Improve strength and thermal stability (PLA/PETG). Metal Cleaning and Finishing: Critical for powder removal and achieving the final surface quality/density of SLM/DMLS parts.

- Q: Can GreatLight print metal belt clips?

Answer: Of course. **GreatLight is good at