Understanding the Power of 3D Printing: Deepening the Printer Anatomy

Ever wonder how a digital blueprint becomes a tangible metal part in a few hours? At the heart of this innovation is the complex design of industrial 3D printers. As a leader in rapid prototyping (especially for complex metal components), Greatlight Leverairs Outwlight Leverairs Perceded Relective Laser Melting (SLM) technology. To uncover the mystery of this process, let’s dissect a typical SLM 3D printer diagram. Understanding its components is more than just a technical term; it is key to unlocking efficiency, accuracy, and manufacturing reliability.

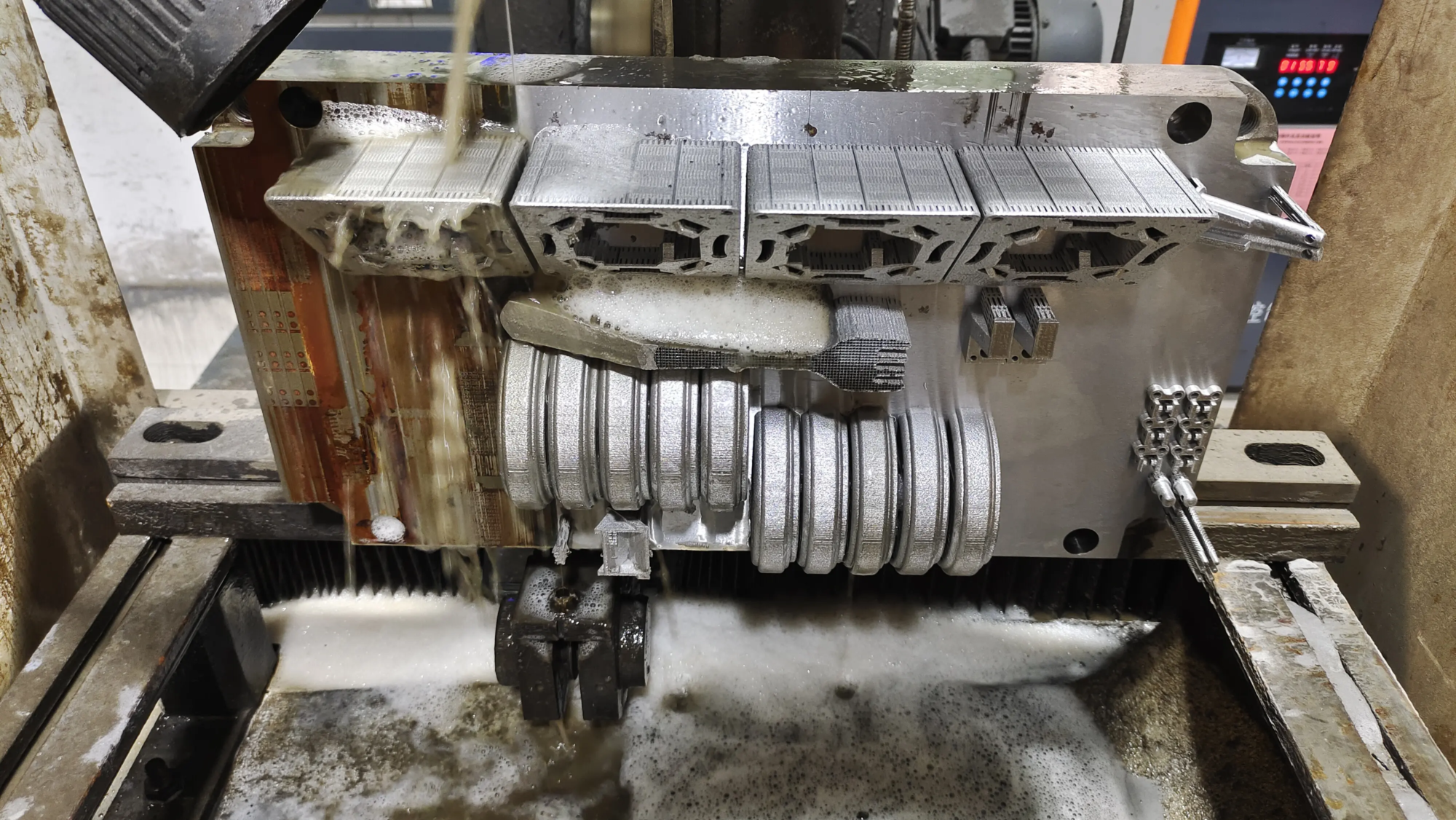

SLM 3D Printer Diagram: Components

1. Building Room

Purpose: The sealed, temperature controlled environment is filled with inert gases (such as argon or nitrogen).

Why it matters: The oxidation of reactive metal powders (eg, titanium, aluminum) is prevented during melting. Greglight’s Chambers maintains near perfect atmospheric conditions and is essential for aerospace or medical-grade parts.

2. Powder conveying system

Element:

- Powder hopper: Storage unit of raw metal powder.

- Recoater Blade/Roller: Precisely spread thin layers (20-60 microns) of powder throughout the platform.

Innovative insights: Greatlight uses automatic powder treatment to minimize human errors, ensure consistent layer density and reduce waste.

3. Laser scanning system

Core parts:

- High power fiber laser: A focus beam (maximum 1 kW) is emitted.

- Galvo Mirror: High-speed mirrors turn the laser toward the powder bed with micron accuracy.

Working accuracy: The laser selectively fuses the powder layer, oriented by sliced CAD data. This makes it impossible to make complex geometric shapes impossible by conventional machining.

4. Build a platform

Function: A movable board that will gradually drop after each layer. When immersed in powder, support the growing part.

Material expertise: Greatlight optimizes platform materials (e.g., heated stainless steel) to minimize residual stress in critical components such as turbine blades.

5. Cooling and filtration systems

Key roles:

- Heat exchanger: Adjust the chamber temperature to prevent warping.

- Filter: Capture stray particles from the inert gas cycle.

Reliability factors: Robust cooling ensures dimensional stability, while filtration extends hardware life – uninterrupted production.

6. Control Units and Software

The backbone of SLM:

- Slicing software: Convert 3D models to machine-readable layer instructions.

- Real-time monitoring: Sensor detection defects (e.g., uneven melting) intermediate construction.

Greglight’s Edge: Proprietary software integrates AI to predict and compensate for thermal distortion, thereby improving the accuracy of parts.

How it all comes together: SLM Process Workflow

- Level 1: Powder spreads; laser melts the first cross-section of the part.

- Level 2: Platform lowered; Recoater added fresh powder; laser melted the next layer, bonding it to the previous layer.

- Finalized: The unadded powder was recovered; this part was subjected to a pressure-stimulated heat treatment.

- Post-processing (Greglight Specialty): CNC machining, surface polishing or heat treatment can achieve final specifications.

Why this crash is important to manufacturers

For engineers, consider 3D printers as "Black box" Authorized design innovation. Recognizing how laser power interacts with powder properties or how indoor atmosphere affects material properties allows:

- Faster iteration cycles.

- Optimized support structure.

- The waste rate is reduced.

At Greatlight, this technology is masterful in turning into reliable rapid prototyping. Our SLM farms always produce functional metal parts with tolerances of less than ±0.1 mm in a few days rather than weeks.

in conclusion

Demysinging 3D printer diagram reveals the miracle behind the engineering-grade additive manufacturing industry. From inert gas management to real-time laser calibration, every component must be coordinated. Greatlight embodies this synergy – bringing precise SLM machinery, materials science expertise and automated post-processing. For product teams that require end-to-end solutions, we transform complex designs into powerful prototypes at an unrivalled pace. Ready to break the boundaries? Work with Greatlight to quickly create your competitive advantage.

Optimize your product development – Connect to custom metal parts quotes for Greatlame!

FAQ (FAQ)

Q1: What metals can be 3D printed through SLM?

Greatlight process stainless steel (316L), titanium alloy (TI64), aluminum (Alsi10mg), cobalt pink, etc. Supports custom materials (e.g., inconel).

Q2: How accurate is SLM printing parts?

Laser spot sizes are as small as 50μm and layer resolutions are as low as 20μm, and we achieve dimensional accuracy of ±0.1 mm in most builds. It can be tightened further after the operation.

Q3: Will recycling powder affect the quality of parts?

Our inert gas screening stations ensure that reused powders retain the optimal fluidity and chemical compositions that are verified by strict quality inspection protocols.

Q4: Can SLM handle large parts?

Yes. Greglight’s printer supports builds up to 500 x 280 x 400 mm. Larger components can be printed as segments and soldered.

Q5: What post-processing options exist for metal parts?

We offer CNC machining (for critical surfaces), firing (fatigue resistance), polishing (RA ≤0.8μm), heat treatment (pressure relief), and coatings (e.g. anodizing).

Q6: Why choose SLM instead of CNC for prototype?

Ideal for lightweight remains, internal passages and high-strength geometry. The average SLM turnover time for complex CNCs is 3-5 days, while 1-3 weeks.

Question 7: How does Greatlight ensure partial integrity?

Parts are subjected to CT scans, tensile testing and microstructure analysis before transport – exceeding ISO 9001:2015 standards.

Question 8: Do you support small batch production?

Yes. Greatlight excels in single-use prototypes and batches of up to 10,000 units using automatic powder processing systems.

Greghime: Your end-to-end partner in the metal additive manufacturing industry. Customize precision parts at competitive speeds and are customized by speed, innovation and trust.