The Ultimate Guide to 3D Printer Overhang Testing: Mastering Complex Geometries

Every 3D printing hobbyist or engineer who dares to try to go beyond the basic cube struggles with overhangs. The elegant curves in the sculptures, the intricate lattices in the functional parts, the critical angles of the cooling ducts – they all push the limits of how materials can be deposited in thin air. Success depends on understanding the capabilities of the machine, which is 3D Printer Drape Test Become indispensable. This is not just a test; It’s a window into the printer’s performance on complex geometries.

Why Drapes Are the Achilles’ Heel of 3D Printing

At its core is fused deposition modeling (FDM) and similar processes built layer by layer. Each new layer requires adequate support from the layer below to bond and cool properly without sagging, warping, or separating. one drape This happens when part of the new layer exceeds the coverage of the layer below it. The larger the angle (measured from vertical), the less supportive the protruding material will be.

- challenge: Gravity is not interrupted during printing. Without adequate support (either from underlying layers or supporting structures), filamentous materials can sag, curl, or create a rough, filamentous surface. This destroys aesthetics, dimensional accuracy, mechanical strength, and ultimately part functionality.

- critical angle: Most printers have a "critical overhang angle." Below this angle (e.g., 45 degrees), the printer can usually produce reasonably good quality without a support structure. Beyond this angle, quality degrades significantly without intervention. However, this angle is not a universal constant – it can vary greatly depending on the material, printer, nozzle temperature, cooling settings, print speed and layer height.

Why run a specialized drape test? (Beyond trial and error with real parts)

- Quantitative ability: Go beyond guesswork. Test model objectively measures maximum overhang angle Your specific printer and settings can handle reliably.

- Material and settings optimization: Test how different filaments (PLA, PETG, ABS, Nylon, etc.), temperature, fan speed, layer height, and print speed affect draping performance. Find the best settings for challenging designs.

- Calibration and diagnostics: Isolate drape issues caused by mechanical issues (e.g., insufficient cooling, extruder jump, shaft wobbling) from inherent material/slicer limitations.

- Predicting real-world success: Understand your printer’s limitations and gain confidence in printing complex models. Avoid failed prints and wasted time/materials.

Designing and Running Drape Tests: A Step-by-Step Guide

Well-designed test models are key. Common designs include:

- wedge: A simple vertically printed triangular prism with the angle on one side gradually increasing from 0° (vertical) to nearly 90° (horizontal). Easy to visualize and measure.

- Cylinder/Sphere: Has an inherent drape characteristic that increases towards the top. Suitable for testing beautiful curves.

- Combination test: Models containing multiple overhang angles (e.g., 30°, 45°, 60°, 70°, 80°) often feature bridges and other challenging features.

How to test:

- Select or design a model: Choose a test STL that suits your goals (e.g., wedge for precise angle measurements, cylinder for curved surfaces). Websites like Thingiverse or Printables offer a wide range of designs.

- Strategic slicing:

- No support: This is crucial! The purpose of this test is to find Not supported limit.

- Control variables: Use consistent settings except for the variables you are testing (e.g. material, cooling, speed). Start with your standard quality profile.

- Floor height: Thinner layers usually handle overhangs better but increase print time. The standard 0.2mm is usually a good starting point.

- speed: Slower speeds give the cooling fans more time and reduce inertia forces, often improving overhang. consider a "overhang speed" Make settings in slicer.

- cool down: Maximum cooling is usually necessary. Make sure the overhang layer’s part cooling fans are running at 100% speed. Verify proper airflow direction and fan functionality.

- temperature: Slightly lowering the nozzle temperature can increase the cooling solidification rate, but too low will result in poor interlayer adhesion. Test step by step.

- Bridge settings: These often affect steep overhangs. Adjust flow and fan speed specifically for the bridge section.

- Carefully printed: Print the model on a flat bed. Monitor the initial layer for good adhesion.

- Analysis results: Check the printed test piece carefully:

- Determine the angle at which noticeable sagging, curling, rough surface finish, or failed layers begin.

- Note whether the sagging starts at the edge or across the entire surface.

- Listen to the sounds during the print process – excessive clicking sounds may indicate a skipped step due to resistance from the curled material.

Interpret results and resolve poor drape issues

- this "good enough" angle: Determine the highest angle acceptable for surface quality For your specific application (Tolerances may differ between visible surfaces and hidden features).

- Common trouble signs and fixes:

- Sagging/Sagging: Mainly caused by insufficient cooling. Solution: Increase cooling fan speed Dramaticallyreduce print speed specifically for overhangs, lower nozzle temperature slightly, check fan duct efficiency/cleanliness.

- crimping: Usually related to cooling imbalance or material shrinkage (common in ABS/ASA). Solution: Maximize part cooling, ensure even airflow around the nozzle, increase print speeds with pre-curl layer lift, consider providing enclosures for materials prone to warping, or use an adhesion promoter. Lower bed temperature slightly after initial layer possible ABS help.

- Rough/shark skin texture: Can indicate vibration, insufficient overhang extrusion, or cooling issues. Solution: Check mechanical stability (belt tension, frame stiffness), ensure correct extrusion calibration (step E), increase drape flow slightly, optimize cooling.

- *Complete layer failure (sagging spots): The overhang exceeds the capabilities of the current setup. Solution: Add support structures to realistic models For angles beyond your determined stability limitsrevisiting temperature/cooling/speed optimization.

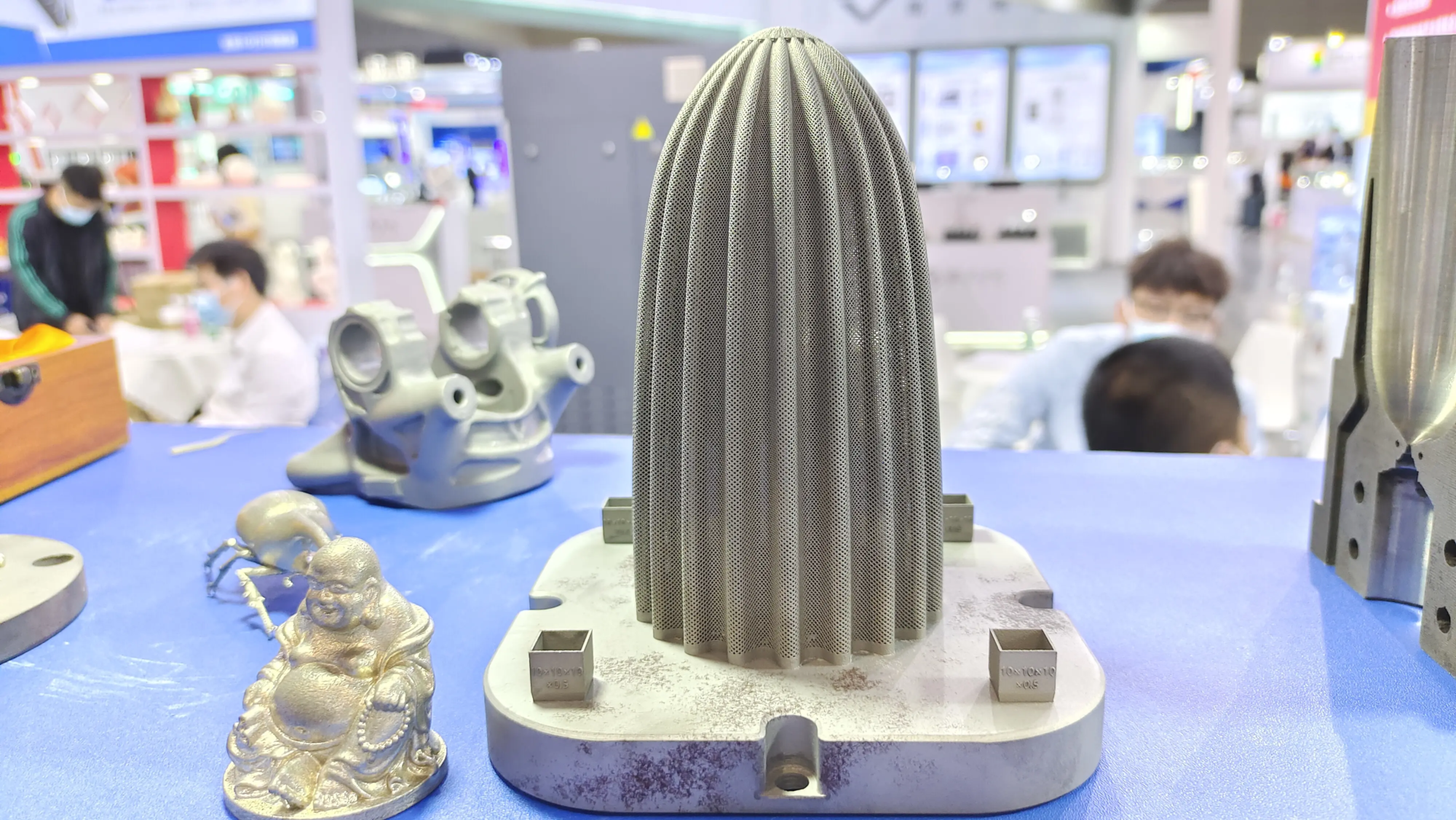

Advanced techniques for pushing the limits of overhang (especially important for metal additive manufacturing)

Although FDM principles are widely applicable, demanding applications, especially in Metal Additive Manufacturing (AM) like Selective Laser Melting (SLM) – Technical core GreatLight’s advanced rapid prototyping capabilities – Need higher precision:

- Optimized scanning strategy (SLM): The pattern and direction of laser melting of each layer significantly affects heat distribution and residual stress, and thus overhang stability.

- Support structure engineering: In metal additive manufacturing, supports are often unavoidable. They are designed to Effective heat dissipation and Minimal post-processing removal worka key consideration Gretel solved it carefully Its one stop shop.

- Subcutaneous parameters: Slicers for metal powder bed fusion allow highly specific parameter adjustments to downward-facing surfaces (overhangs). Adjusting laser power, speed, profile line spacing, and layer thickness is critical.

- Thermal management: In polymer and metal additive manufacturing, controlling the thermal environment (chamber temperature, inert atmosphere for metals such as titanium or aluminum) is critical to prevent deformation of unsupported areas.

Conclusion: Knowledge is power (and quality)

Overhang testing is more than just a calibration step; it is fundamental research and development for your specific 3D printing workflow. By systematically understanding and pushing the limits of unsupported overhang of your machines and materials, you can confidently create truly complex and fully functional parts. You go from hoping that print will work to knowing It will be based on quantifiable data. Remember, limitations discovered are not failures, but knowledge gained – used to inform smart support usage or setup improvements.

Suitable for professional applications, especially demanding applications Metal prototypes and end-use production parts push the boundaries of designcollaboration with experts becomes crucial. GreatLight utilizes state-of-the-art SLM equipment and deep production expertise Solve extreme overhangs and complex geometries in a variety of metals. Our comprehensive One-stop post-processing (machining, heat treatment, surface finishing) Ensure parts meet strict dimensional and aesthetic requirements, overcoming challenges that can arise with desktop printers or lack of expertise.

FAQ: 3D Printer Overhang Testing Revealed

Q1: What is "OK" What is the overhang angle of my printer?

A: There is no single answer. PLA on a well-tuned printer can withstand temperatures of 60-70 degrees without support, while ABS may struggle to exceed 45 degrees without optimized cooling/casing. the only way to know your The limit is passing the test. Metal additive manufacturing typically needs to support angles greater than about 45 degrees, although advanced parameter adjustments can sometimes push it a little further.

Q2: I get curls even at low angles. What’s wrong?

Answer: This strongly indicates Insufficient cooling of parts. Verify that your cooling fan is working properly, reaching 100% speed on the layer that requires it, and that airflow is effectively directed to the nozzle tip. Also, check for partial blockages that may affect extrusion consistency.

Q3: Should I always use supports for angles outside my testing limits?

A: Generally speaking, yes, for functional parts or visible surfaces where quality is required. Sometimes, minor cosmetic defects may be acceptable within absolute limits. For critical strengths or tight tolerances, bracing beyond the stable unbraced angle is recommended.

Q4: Is the overhang test suitable for resin printers (SLA/DLP)?

Answer: Yes! Although the physics are different (solidification vs. melting), the concept remains. Resin has superior inherent drape capabilities (generally supporting steeper angles than FDM), but extreme angles or large unsupported areas can still cause failure or deformation due to suction and resin flow dynamics. Test against your resin and setup.

Q5: Can GreatLight handle parts with extreme overhangs?

one: Absolutely. as a leader Precision Metal Rapid Prototyping (SLM), Honlite has advanced equipment, understanding of materials science and specialized process engineering expertise Required to successfully manufacture parts with highly complex geometries and challenging overhangs. our Comprehensive post-processing Features further ensure that all necessary support structures are cleanly removed and the final part meets exacting specifications. We specialize in effectively solving rapid prototyping challenges.

Ready to push your design boundaries? Stop fighting against overhang limitations and material limitations. Leverage Honglaite’s professional rapid prototyping services Transform your most ambitious concepts into high-precision metal reality. Get a custom quote today and experience the difference that deep additive manufacturing expertise makes!