Keeping your 3D printer running smoothly: A basic guide to lubrication

In the dynamic world of 3D printing, whether you are a hobbyist fine-tuning a desktop FDM machine or an engineer overseeing the production of industrial metal powder printers such as SLM (Selective Laser Melting), there is one aspect that remains universally important but often underestimated: proper lubrication. Don’t think of 3D printer grease as an optional accessory, but as the vital lifeblood of your machine’s motion system, ensuring longevity, accuracy, and smooth operation. Neglecting it can result in premature wear, reduced print quality, annoying noises, and ultimately costly downtime and repairs.

This guide clears up the confusion and dives into the science and practice of 3D printer lubrication for polymer and advanced metal systems.

Why is grease so important?

- Friction Fighter: Lubricants significantly reduce friction between moving metal parts (rails, bearings, screws), thus minimizing wear. This is critical for lead screws and linear guides that are subject to constant loads.

- Precision protector: Smooth, consistent movement is the foundation of accuracy. Friction can cause inconsistent motion (stiction), resulting in layer shifting, ringing, and dimensional inaccuracies.

- Corrosion Inhibition: Especially in environments prone to moisture or exposure to chemicals (such as some post-processing), grease can form a protective barrier on metal surfaces.

- Fragment management: Some greases help trap and expel tiny dust and debris particles generated during the printing process or in a shop environment, preventing them from acting as abrasives.

- Reduce noise and vibration: Friction causes vibration and noise. Proper lubrication ensures quiet, smooth operation.

- Longevity Investment: Protected components last significantly longer, protecting your substantial investment in the printer itself.

Interpreting Oils and Greases: Types and Chemical Composition (Not All Oils and Greases Are Created Equal!)

Choosing the right grease isn’t about grabbing the nearest tub in the garage. Using the wrong type can damage components or attract damaging particles. Let’s break down common chemicals:

-

Lithium-based grease (white lithium):

- Chemical: Lithium soap thickens mineral or synthetic oils.

- advantage: Very common, affordable, general purpose lubricity, water resistant (emulsifying).

- shortcoming: Over time it attracts dust ("Apply oil"), the performance decreases at high temperatures and the viscosity is generally thicker.

- Use cases: Older printers were designed to be slower and have moderate load points. Use with caution on modern high-speed and high-count printers – make sure they meet OEM specifications.

-

PTFE-based grease (Teflon grease):

- Chemical: Usually lithium or other soap base, infused with PTFE (polytetrafluoroethylene) particles.

- advantage: Provides extremely low coefficient of friction. The PTFE particles act like miniature ball bearings. Typically comes in a cleaner white or translucent form that is less likely to attract dust than standard lithium. Good temperature stability.

- shortcoming: Typically more expensive than basic lithium grease.

- Use cases: One of the most popular and recommended choices for mainstream FDM/FFF printers. Ideal for linear guides, lead screws and bearings where low friction is critical. Usually the standard recommended by the OEM.

-

Silicone grease:

- Chemical: Based on silicone oil and containing thickener.

- advantage: Highly water-resistant, very stable over a wide temperature range, excellent dielectric properties, and essentially inert. Will not swell common rubber/plastics (important around belts and plastic parts). USP: Great for waterproofing.

- shortcoming: Generally there are reduce For metal-to-metal contact, lubricity (load-carrying capacity) is better than PTFE or lithium-based greases. Not ideal for high load points such as lead screws or densely loaded rods.

- Use cases: Protecting shafts/surfaces from corrosion in wet environments, lubricating seals/O-rings, plastic/rubber contact points are the main concerns. Often misused on metal motion systems. For use where corrosion rather than heavy mechanical lubrication is the primary concern.

- Synthetic high-performance grease:

- Chemical: Usually polyalpha olefin (PAO) or ester-based synthetic oil containing complex thickeners (such as polyurea, calcium sulfonate complex). May contain advanced additives.

- advantage: Excellent high temperature performance and stability, excellent oxidation resistance, long service life, very clean (low evaporation/dust pickup), many provide excellent protection against wear and corrosion. Often tailored for specific extreme conditions.

- shortcoming: Much more expensive than hobby grease.

- Use cases: Essential for industrial-grade printing. It is crucial for high-speed SLM/DMLS metal printers, which operate at high temperatures and require stable performance. Also ideal for printers in FDM production environments and hot shops that require high duty cycles.

The Golden Rule: Consistency (NLGI ratings matter!)

Besides chemistry, another key identifier is NLGI levela measure of penetration depth (how much the cone sinks into the grease), indicating its consistency or stiffness.

- NLGI #0 and #1: Fluid consistency. Suitable for closed bearing or slow moving wipers. Rarely used for open rails/screws on printers.

- NLGI#2: The most common designation grade for 3D printers. Semi-fluid paste. Provides the right balance between adhesion (staying in place) and the ability to spread to contact points without creating excessive resistance to moving parts. Typical speeds for most Cartesian and CoreXY printers.

- NLGI#3: The paste is stronger. For high load, low speed applications. Generally not recommended unless specifically recommended by the manufacturer for highly loaded components on heavy duty machines. Drag occurs when driving at high speeds.

Application: Art "less is more"

Effective use of grease is just as important as choosing the right grease:

- Cleanliness first: Cleanliness is the most important thing. Thoroughly clean components (rails, screws, bearing raceways) using a lint-free cloth moistened with isopropyl alcohol (99%). Remove all old grease, dirt and debris. Any contaminants mixed with the new grease will accelerate wear.

- Apply with caution: Grease is not paint. You need a very thin, almost transparent film. Over-lubrication is a common mistake:

- Attracts excess dust and debris, forming an abrasive paste.

- Lubricity is reduced because thick layers absorb heat and shear forces.

- Increased resistance may affect print quality.

- Reapplying is key: Grease doesn’t last forever. It can degrade, dry out, become contaminated, or become displaced. Factors affecting frequency:

- environment: Dusty/hot workshops require more frequent applications.

- usage: High duty cycle production machines require more frequent lubrication.

- Grease type: High-performance synthetic materials last longer than base lithium.

- Element: The lead screw usually requires more attention than the slow-moving Z-axis rod.

- General guidelines: Check every 200-500 printing hours. Wipe off old residue (if visible and dirty) and reapply very thin Layer every 6-12 months on desktop printers; more frequently on production units. See your printer manual!

- document: Simply record the type of grease used and the date it was used on each printer component.

Thinking Beyond the Desktop: Industrial and Advanced Considerations

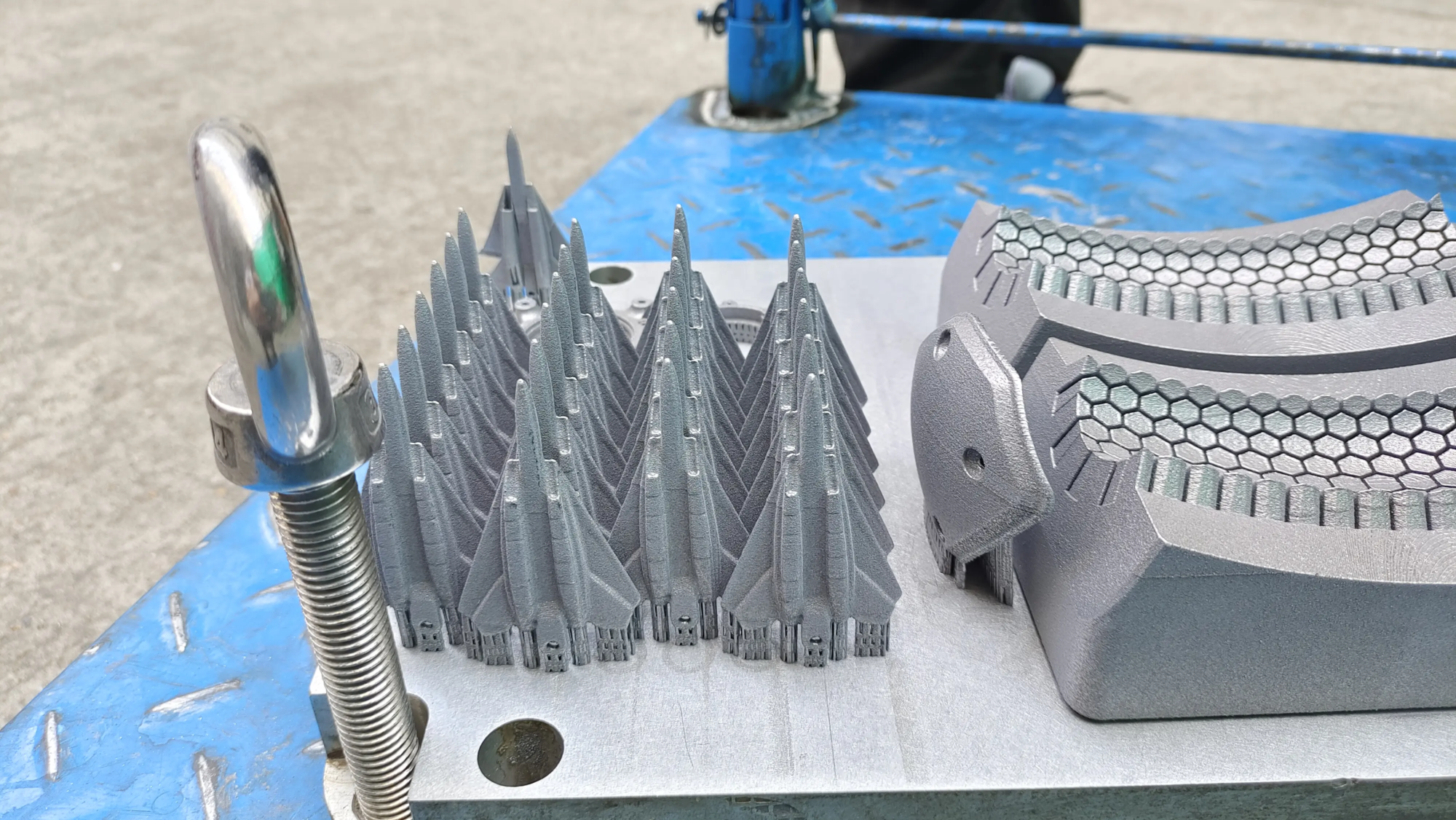

For companies like GreatLight that operate hundreds of thousands of dollars worth of advanced SLM metal 3D printers or run large-scale production FDM farms, lubrication protocols go beyond hobbyist practices:

- OEM requirements: Industrial machines have clearly designated greases (brand, type, NLGI rating). Deviating from this may void the warranty and result in catastrophic failure. Around the laser chamber, high temperature resistant grease cannot be ignored.

- Precision dispensing: Using a precision grease gun ensures controlled and consistent application, avoiding under- or over-lubrication.

- Book for the afternoon: Lubrication is strictly scheduled within a comprehensive preventive maintenance program and managed using tracking software.

- Special grease: Unique requirements require specific formulations—extremely low temperature grease for cryogenic cooling systems, food-grade grease for medical device printers (processed in post-processing), or conductive grease for specific electrical contacts. Expertise is important here.

- Dust Control: Industrial environments implement strict housing sealing and air filtration to minimize dust contamination and extend grease life and effectiveness.

Conclusion: Grease – a small detail with a huge impact

Don’t overlook the humble grease gun. Proper and consistent use of the right lubricant is arguably one of the most cost-effective investments you can make in your 3D printing journey, whether it’s your desktop workhorse or a suite of industrial metal printers. It guarantees accuracy, protects your substantial investment, minimizes downtime due to failures, and ultimately ensures consistent, high-quality output. For the amateur, using the appropriate PTFE or specified synthetic grease, and applying it with care, will yield significant benefits. For industrial applications and specialty shops like GreatLight, strict compliance with OEM lubrication specifications as part of a robust maintenance strategy is the foundation for operational excellence and profitability. Respect your printer’s moving parts – keep them clean, properly lubricated, and they’ll give you smooth performance and a long life.

FAQ: Your 3D printer grease questions answered

-

Q: Can I just use WD-40?

- Answer: Absolutely not. WD-40 is a penetrating agent, displacing agent and solvent. Not a lubricant. It washes away existing grease, fails to provide long-term lubrication, and actually increases friction and attracts dirt quickly. Using it on rails or screws can damage them.

-

Q: Will grease damage belts?

- A: Yes, grease can severely damage belts. Do no Lubricate the timing belt! Grease can degrade the rubber/polymer and cause the belt teeth to slip or peel. Keep the belt clean and dry. If necessary, use a dedicated belt cleaner or Very smallest dry Lubricant designed specifically for belts, use with extreme caution.

-

Q: My printer uses sticks. What grease should I use?

- one: The principles remain the same. PTFE base (NLGI #2) is generally an excellent choice for linear rods and bushings. Make sure the bushings are compatible (some porous sintered bushings require specific oils). Clean and apply a thin film.

-

Q: How often should I clean and re-lubricate?

- one: As a baseline, check every 200-500 machine hours. If the residue looks dirty, dry, or insufficient, clean and reapply a very thin film. For heavily used production machines, this might be once a month. For lighter hobby use, every 6-12 months is usually sufficient. Check your manual and observe the performance/sound. If the movement feels gritty or you hear an unusual scraping/whining sound, clean and re-lubricate immediately.

-

Q: Can I mix different types of grease?

- Answer: Generally not encouraged. Different greases may be chemically incompatible—some mixtures may soften, harden, or separate, losing lubricity and possibly causing damage. Be sure to completely remove the old grease before switching to a different type. If possible, stick to one type per application point.

-

Q: How important is the NLGI rating?

- Answer: Very critical. NLGI #2 is the best choice for most axis movements on a typical printer (lead screw, linear guide). Using thicker No. 3 grease on the fast rail may cause excessive drag and motor strain. Using fine #1 may not stay in place effectively. Always try to match OEM specs if available.

-

Q: Yes "triple" Is it okay to use household oil?

- Answer: Not recommended for continuous lubrication points such as guide rails and screws. Lightweight motor oil is too thin, has poor adhesion, and will quickly run off or collect dust. They are more suitable for providing temporary relief in bearings designed for oil rather than as the primary lubricant for grease-covered motion systems.

- Q: We need medical/biocompatible metal parts. Does grease matter?

- Answer: The key is. Although grease is not usually used directly Parts are processed during the SLM process yes Widely used in printer motion systems and processing components. If the part touch Having lubricated surfaces during disassembly or post-processing, NSF H1 food grade or specific biocompatible grease Products certified for incidental exposure must be used in these areas. Our post-processing protocol takes this into account on GreatLight for sensitive applications.

Protecting your equipment investment and ensuring optimal performance starts with understanding the basics of precision lubrication. Custom precision rapid prototyping parts require reliable machinery maintained to the highest standards.