As the world of 3D printing continues to evolve, the energy consumption of these innovative machines must be considered. 3D printing has revolutionized the way we design, prototypify and manufacture products, but it is crucial to understand the power usage of these devices to optimize their performance and reduce environmental impact. In this article, we will dig into the world of power usage of 3D printers, explore factors that affect energy consumption, different types of 3D printing technologies, and the steps that can be taken to reduce power usage.

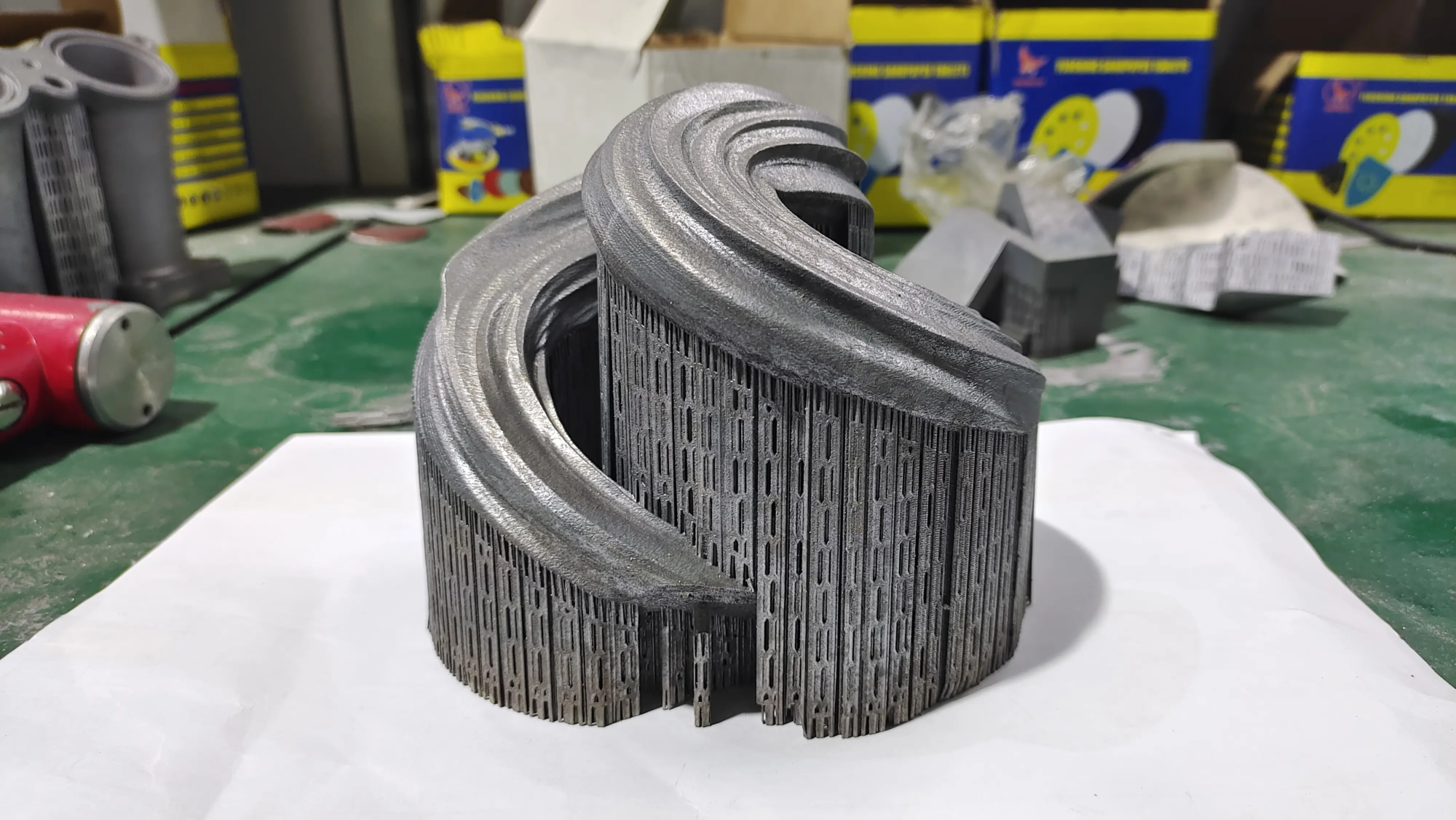

First, it is necessary to understand that 3D printing technology is a broad term covering a variety of technologies, each with its unique characteristics and energy requirements. The most common types of 3D printing techniques include fusion deposition modeling (FDM), stereolithography (SLA), and selective laser melting (SLM). Each of these technologies has a different power consumption pattern, depending on factors such as the size of the print, the complexity of the design, and the materials used.

For example, FDM is one of the most widely used 3D printing technologies, especially in hobbyists and education. FDM 3D printers typically consume between 50-200 watts of power, depending on the specific model and print settings. However, some high-end FDM printers can consume up to 500 watts or more, especially when printing with high-temperature materials.

On the other hand, SLA and SLM 3D printing technologies tend to be more power consuming due to high-energy lasers or light sources used to heal or melt printing materials. SLA printers can consume anywhere from 100-500 watts, while SLM printers range from 500-2000 watts or more depending on the specific model and printing parameters.

Several factors can affect the power consumption of a 3D printer, including printing speed, layer thickness, and fill density. Faster printing speeds and thicker layer thickness tend to increase power consumption, while higher fill density can reduce energy use. Additionally, the type of printing material used can also affect power consumption, some of which require higher temperatures or more energy to print.

To reduce the power consumption of 3D printing, several strategies can be adopted. One approach is to optimize the print settings, such as reducing the printing speed or layer thickness, to minimize energy use while maintaining acceptable print quality. Another approach is to use energy-efficient printing materials or to develop new materials that require less energy.

Additionally, some 3D printer manufacturers are incorporating energy-saving features such as sleep mode or automatic shutdown into their designs to reduce power consumption when the printer is not used. Additionally, the use of renewable energy sources, such as solar or wind, can help reduce the carbon footprint of 3D printing operations.

In short, power consumption of 3D printers is a key aspect of the 3D printing process, and understanding the factors that affect energy consumption is crucial to optimize performance and reduce environmental impacts. By choosing energy-saving printing technology, optimizing printing settings and combining energy-saving functions, 3D printing can become a more sustainable and environmentally friendly manufacturing process.

FAQ:

Q: How much power does a 3D printer consume?

A: The power consumption of a 3D printer depends on the technology, the printing setup and the type of material used. FDM printers typically consume between 50-200 watts, while SLA and SLM printers range from 100-2000 watts or more.

Q: What factors affect the power consumption of 3D printers?

A: Several factors can affect power consumption, including printing speed, layer thickness, fill density, and the type of printing material used.

Q: How to reduce the power consumption of 3D printers?

A: Strategies to reduce power consumption include optimizing print settings with energy-saving materials, combined with energy-saving features such as sleep mode or automatic shutdown.

Q: Can 3D printing be environmentally friendly?

A: Yes, if energy-saving technologies and strategies are adopted, 3D printing can be an environmentally friendly manufacturing process. Some of the benefits of 3D printing are the use of renewable energy and minimal waste generation.

Q: What is the most energy-saving 3D printing technology?

A: FDM and SLA printing technologies tend to be more energy-efficient than SLM printing, although the specific power consumption depends on the printer model and print settings.

ISO 9001 Factory