Revealing the Limits: Comprehensive 3D Printer Torture Test Review

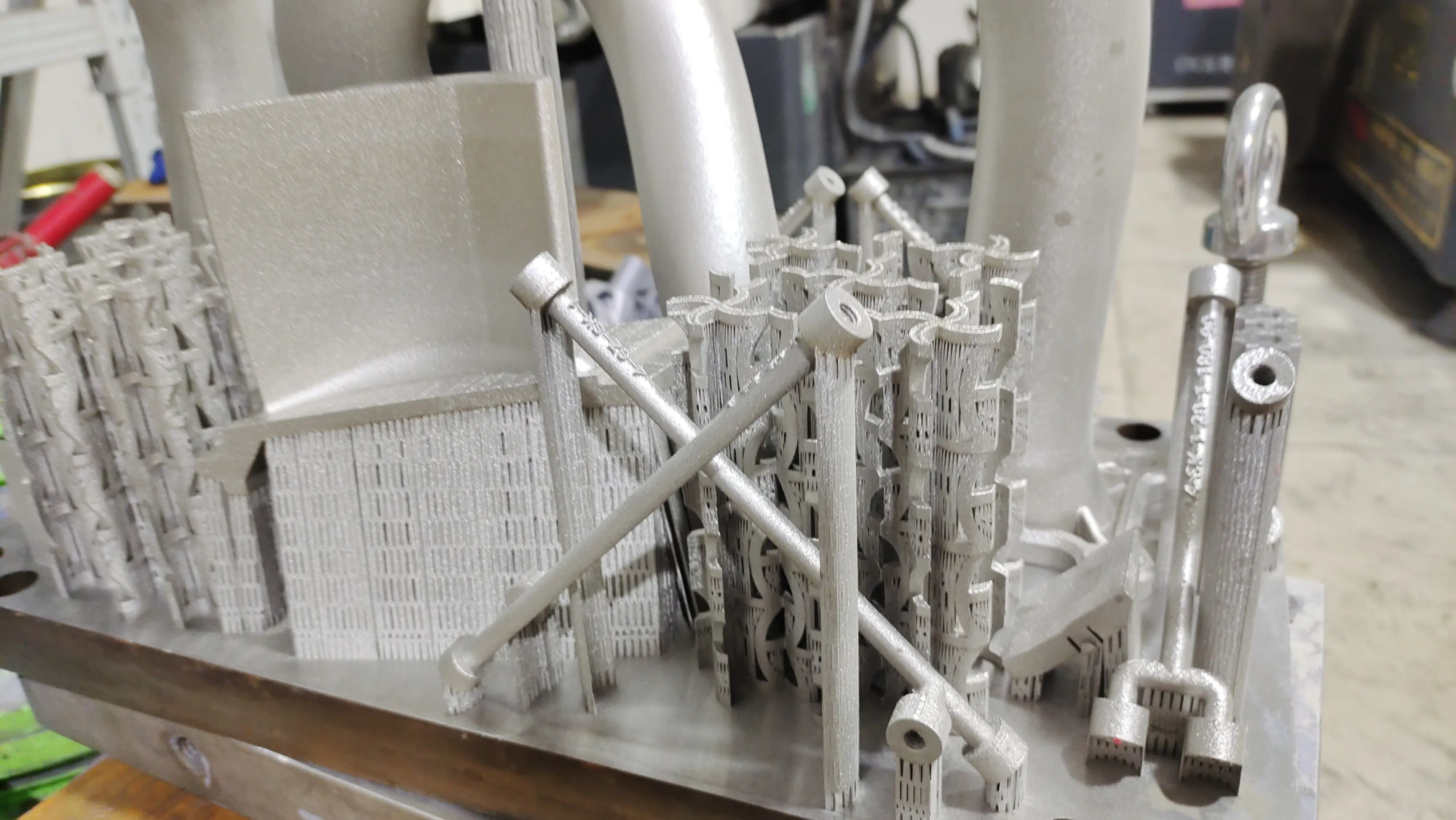

In the world of additive manufacturing, the true measure of 3D printers’ capabilities is not just their speed or solution, but how it handles extreme challenges. Torture testing aims to push printers and materials toward their breakpoints, revealing valuable insights into accuracy, reliability and consistency. exist Greatthe leader of rapid prototypes, we have made our progress SLM (Selective Laser Melting) Metal 3D printers perform hard tests. Here is an honest comment on what these tests require and why they are important to your project.

Why is torture testing not negotiable in 3D printing

The torture test simulates the worst scenario: steep overhangs, intricate bridges, fragile geometry, thermal stress and details. For the aerospace, medical or automotive industries, partial failure is an option, and these tests verify whether the printer can be delivered:

- The accuracy of dimensions (Tolerance ≤0.1mm)

- Structural integrity Under pressure

- Material consistency (For example, avoid warping/cracking)

- Surface quality No post-processing

Without rigorous testing, hidden defects in calibration, cooling or material fusion can lead to expensive pre-production failures.

Torture Test Kit: What We Evaluate

Using industry-standard benchmark models and the challenge of custom design, we evaluated SLM printers in five key parameters:

-

Overhanging and bridges ( "Unsupported Survival" test)

- challenge: Print 70°–90° overhang and 20mm+ bridge without support.

- result: The SLM printer maintains overhang integrity of >85° and can reach 25mm without vertical bridges. Precise laser control minimizes heat distortion and is critical for turbine blades or lightweight relics.

-

Microscopic detailed fidelity ( "maze" test)

- challenge: Copy the sub-0.5mm function (e.g., threading, pores, text engraving).

- result: Due to the size of the 20–50μm laser spot, the consistent reproduction of 0.2mm details. Ideal for surgical tools or microfluidics.

-

Mechanical stress ( "Vortex cylinder" test)

- challenge: Thin-walled (<0.5mm) cylinder under torsional load.

- result: During the printing process, zero break of 15 n·m torque caused by uniform layer adhesion is achieved due to the inert argon environment.

-

Material versatility (multi-alloy endurance)

- challenge: Switch between reactive alloys without cross contamination (TI64, ALSI10MG, Inconel 718).

- result: No porosity or oxidation, with material properties matching ASTM standards. More than 20 metal alloys are supported.

- Thermal shock ( "puck" cycle)

- challenge: Quick cycle between -50°C and 300°C.

- result: Negligible deformation – Full fusion fusion of SLM prevents layering with adhesive-based methods.

Greglight’s Edge: Engineering elasticity to every print

Torture testing exposes weaknesses; our SLM technology turns them into advantages:

-

Precise laser mastery:

500W – 1kW fiber laser melts the metal powder with micrometer accuracy to ensure near mesh results. -

Closed-loop quality control:

Real-time optical monitoring detects abnormalities (e.g., splashing, uneven melting) and automatically corrects layer by layer. -

Post-processing capability:

Our one-stop finishing service (HIP, CNC machining, EDM, bead blasting) turns test-verified printing into end-use parts. The tortured bridge is polished to a 3.2μmRA finish, while stress relief treatment enhances fatigue resistance. - Materials Science Expertise:

Work with our metallurgists to bring alloys (from copper (thermal conductivity) to Maraging Steel (impact resistor) to your operational needs).

Conclusion: Why torture tests define the reliability of real-world

Torture tests are not just academic exercises, but you can guarantee to prevent catastrophic failures. exist GreatOur SLM 3D printers are not only "go through" These trials; they redefined the benchmark Speed (up to 40cm³/hr build rate), complexity and repeatability. Whether you are making rocket burners or biocompatible implants, our technology ensures:

- Zero tolerance for defects

- 1:1 digital to physical fidelity

- Scalability from prototype to production

Don’t gamble on untested features. Working with rapid prototyping experts, they have confidence in every layer.

FAQ: Torture Testing and Greatlight Services

Question 1: Why is metal 3D printing more challenging than plastic in torture testing?

Metals require precise thermal control to avoid residual stress, warping or rupture. SLM’s high-energy laser and indoor management solve this – similar to FDM/SLS.

Q2: Can Greatlight run customer-specific torture tests?

Yes. Share your part design, operating environment (e.g., temperature, pressure), and materials. We will create a custom verification protocol.

Question 3: How does post-processing affect the results of torture tests?

Critical! The original print has residual pressure and surface defects. Our hips (thermal isometric pressure) and CNC stages reached a density of 99.9% and eliminated weaknesses.

Question 4: Which industries benefit the most from torture-tested parts?

Aerospace (lightweight, high-strength components), medical (fatigue-resistant implants), automotive (heat-resistant molds) and energy (corrosion-resistant valves).

Q5: How quickly can Greatlight provide torture-verified parts?

Prototype: 3-7 days. Batch production: 2 weeks. Temporary options available.

Question 6: Do you support certification materials (e.g., AS9100, ISO 13485)?

Absolutely. Our facilities comply with international standards and each build is traceable (material batch log, parameter report).

Question 7: Can I submit the design in any format?

We accept steps, STL, OBJ or native CAD files. Our engineers will optimize topology and printing orientation for maximum flexibility.

Are you ready for your design?

Gregtime is not only a manufacturer, but also your verification partner. Upload your project files for free torture testing analysis and [GreatLightRapidPrototyping.com]. Precision design. Proven elasticity.