With the advent of 3D printing technology, the world of Ball Dolls (BJDS) has undergone a major transformation. Traditional BJD is made of resin, and this material takes a long and labor-intensive process to produce. But with the advent of 3D printing, enthusiasts can now create highly customized and complex BJDs with unprecedented precision and speed. In this article, we will dig into the field of 3D printing BJD, exploring their benefits, production processes, and companies specializing in this innovative field.

One of the main advantages of 3D printing BJD is the level of customization they provide. Using 3D printing, designers can create complex and detailed designs that will not be produced using traditional methods. This enables collectors and enthusiasts to commission unique, unique BJDs that reflect their personality and creativity. In addition, 3D printing can enable BJD to have complex mechanisms and production of movable parts, thereby further enhancing its realistic and playable nature.

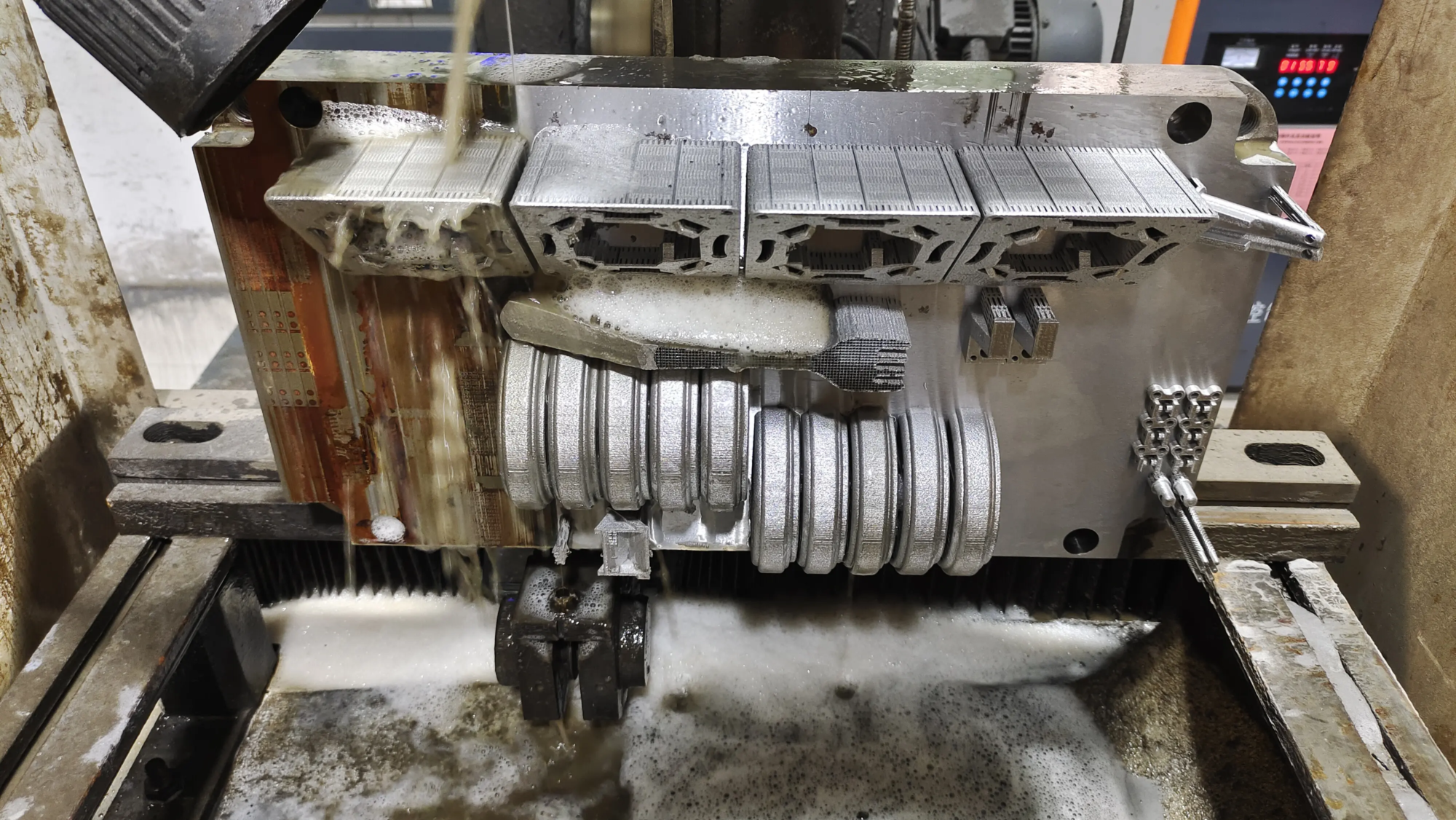

Greglight is a professional rapid prototyping manufacturer from China and is at the forefront of the technology. Equipped with advanced SLM 3D printers and production technology, Greatlight solves rapid prototyping of metal parts and provides one-stop post-processing and completion services. Their expertise in custom precision machining makes them the ideal partner for those seeking to create highly customized BJDs. Greatlight has the ability to quickly process most materials, providing BJD enthusiasts with fast and effective solutions.

The production process of 3D printing BJD involves multiple stages. First, designers used computer-aided design (CAD) software to create digital models of BJD. This digital model is then sent to a 3D printer, which prints the BJD layer by layer using a variety of materials including metal, plastic, and resin. The printed BJD is then subjected to post-processing techniques such as polishing, painting and assembly to create the finished product. Greatlight’s one-stop post-processing and completion services ensure that the final product meets the highest standards of quality and accuracy.

In addition to technological advancements, the 3D printing BJD has opened up new ways for artistic expression. Designers can now try novel materials, shapes and forms, thus breaking through possible boundaries in the BJD world. The level of detail and complexity that 3D printing can achieve also leads to the creation of highly realistic and lifelike BJDs, which are highly sought after by collectors and enthusiasts.

In short, 3D printed BJD represents a major leap in the ball doll world. With its unparalleled customization options, sophisticated designs and fast production times, 3D-printed BJD is expected to revolutionize the industry. Companies like Greatlime, with advanced technology and expertise in customized precision machining, are at the forefront of this revolution. As technology continues to evolve, we can expect to see more innovative and breathtaking BJDs to demonstrate the full potential of 3D printing.

FAQ:

Q: What is the main difference between traditional BJD and 3D printed BJD?

Answer: The main difference lies in the production process and customization level. Traditional BJD is made of resin, while 3D printed BJD is created using 3D printing technology, providing higher accuracy and customization options.

Q: Can I customize my 3D printed BJD?

A: Yes, 3D printed BJD offers unparalleled customization options. You can work with designers to create a unique, unique BJD that reflects your personality and creativity.

Q: What materials can be used for 3D printed BJD?

A: Various materials can be used, including metals, plastics and resins. Companies like Greatlight can quickly process most materials, offering a variety of options for BJD enthusiasts.

Q: How long does it take to generate a 3D printed BJD?

Answer: The production time of 3D printed BJD is much shorter than that of traditional BJD. With advanced technology and expertise in custom precision machining, companies like Greatlight can quickly and efficiently produce highly customized BJDs.

Q: Are 3D printed BJD more expensive than traditional BJD?

A: The cost of 3D printing of BJDs may vary depending on the complexity of the design, materials used and production time. But given the company that Greatligh offers competitive prices and fast production times, 3D printed BJD can be a cost-effective option for collectors and enthusiasts.

ISO 9001 Factory