From digital models to collectible masterpieces: Your ultimate 3D printed Bumblebee guide

For Transformers enthusiasts and manufacturers, few projects are as iconic as creating detailed replicas of Bumblebee. 3D printing can unlock this possibility, allowing complex designs to leap from screen to reality. Whether it is display, role-playing or functional art, printing this beloved automatic mechanism requires careful planning and execution. This guide gradually breaks the process and emphasizes how to make progress Metal 3D printing You can lift your project from cool to favorites.

Why metal is important to wasps

While plastic printers (FDM or SLA) are common, they are often not sufficient for demanding applications. Plastic parts can be fragile, lack quality weight, and can also suffer from limitations of detail. For Bumblebee figurines or functional components (such as custom transmission knobs), Metal 3D printing offers unparalleled advantages:

- Superior durability: Resistant to effects, wear and deformation.

- Real feelings: Achieving the weight and cold touch of advanced robots.

- Outstanding details: Capture precise details (e.g., conversion seams, facial details).

- Material versatility: Alloys such as aluminum, stainless steel or titanium can provide unique aesthetics and characteristics.

- Advanced completion options: The metal parts are beautifully polished and can also be coated with electroplating to get a signed yellow chrome finish.

Your Step-by-Step Wasp Printing Guide

-

Source or design model:

- Start with high-quality 3D models. Well-known websites include Thing Everyse, Cults3D or professional design markets. Find models that are optimized for printing (Water Tright manifold geometry, support friendly orientation). Complex transformation? Consider obtaining a separate articulation assembly.

- hint: search "Bumblebee STL optimized for metal printing" – The model is slightly thickened to indicate structural integrity tends to do the best.

-

Material Selection – Select Alloy:

- Aluminum alloy (e.g., Alsi10mg): Ideal for lightweight models with good strength and smooth post-production effect. Ideal for collectible characters.

- Stainless steel (for example 316L): Ultimate durability and corrosion resistance. Ideal for functional components or highly polished finishes.

- Titanium alloy (TI6AL4V): With extraordinary strength to weight ratio and unique premium appearance. Best for demanding applications.

- Professional insights: Materials science is important. Working with a dedicated metal prototype service ensures that the best alloy is selected for your specific bumblebee model and its intended use, taking into account stress points and the desired aesthetic.

-

Optimization of metal printing:

- Support structure: Metal printing requires complex support. These must be designed to handle thermal stress during printing and can be removed without damaging complex functions.

- direction: Part orientation significantly affects surface quality and stress distribution. Flattening the part maximizes the details on the critical surface.

- Wall thickness and feature size: Detailed elements such as fingers or badges must meet minimum thickness requirements for successful printing.

-

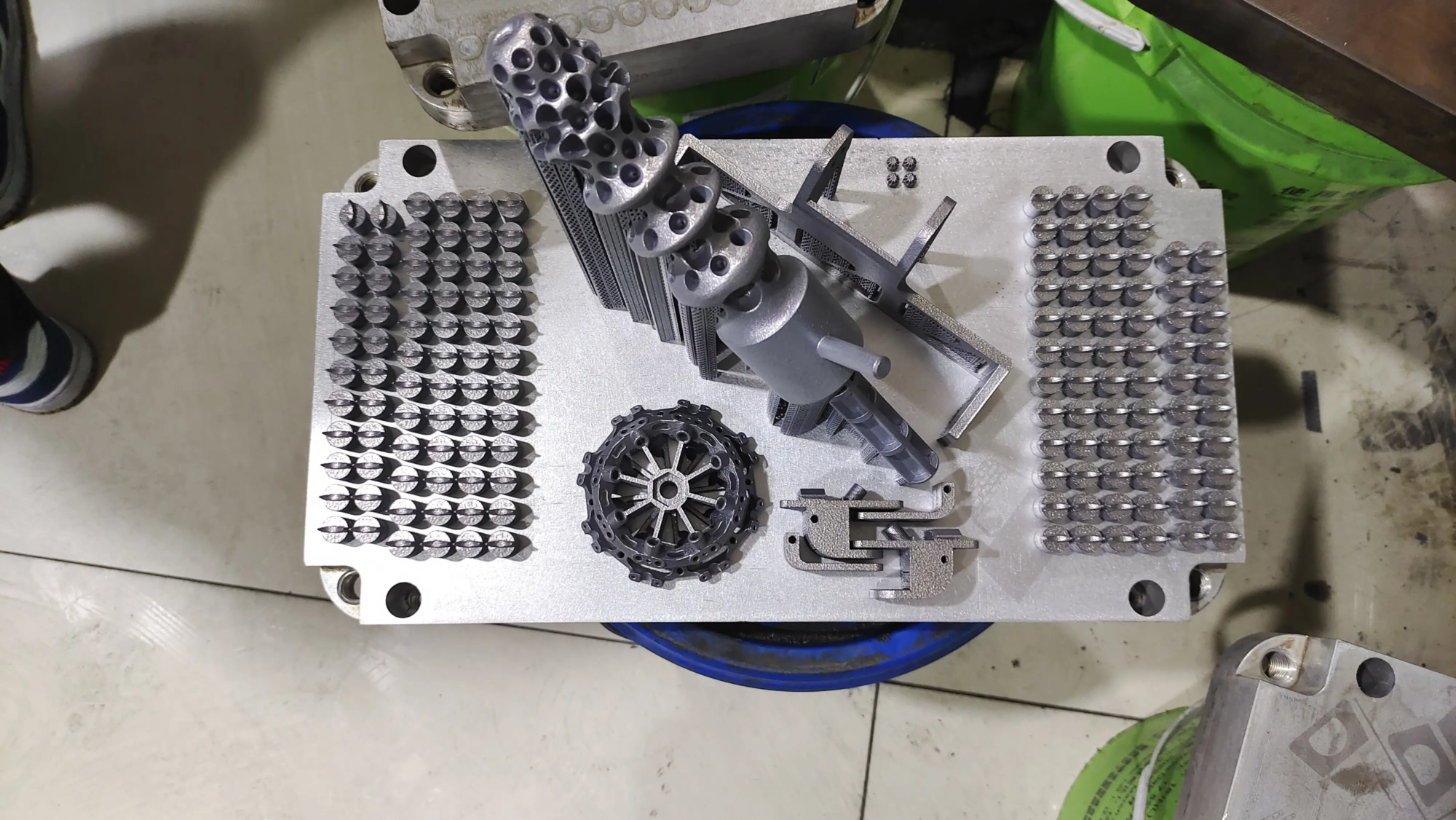

Printing Process – SLM Excellence:

- Selective laser melting (SLM): This is the industry benchmark for precise metal printing. A powerful laser fuses a layer of microscopic metal powder particles to construct impossible complex geometry through traditional methods. SLM is essential for faithfully capturing Bumblebee’s complex armor plates and joints.

- environment: SLM occurs in an inert gas chamber (using argon or nitrogen) to prevent oxidation, thus ensuring partial purity and strength.

- Quality Control: Advanced monitoring systems track melt pool and layer quality in real time to ensure dimensional accuracy and structural integrity throughout the build.

- Advanced post-processing perfect:

- Support removal: Careful manual or CNC-based removal to prevent pressure on delicate components.

- Heat treatment: The pressure-relieving annealing eliminates internal stresses caused by the intense thermal cycling of the SLM, thereby reducing the risk of warping and enhancing mechanical properties.

- Surface finish:

- Grinding/bead explosion: Remove the print lines and create a uniform matte texture.

- Processing/polishing: Achieve precise tight tolerances and mirror-like gloss for critical surfaces.

- Plating/Anodizing: For iconic golden finishes (chrome chrome plating on nickel/copper bases) or durable color anodizing on aluminum. This is transformative in replicating the signature look of Bumblebee.

- painting: Achieve the perfect metallic yellow paint finish requires expert surface preparation and high-quality automotive-grade paint.

Why collaborate with Greatlight Rapid Prototyping?

Bringing complex high-quality metal wasps into life requires not only a printer, but more. it takes Expertise, advanced technology and comprehensive service methods. As a leading professional rapid prototyping manufacturer, Great Specializes in solving complex metal parts challenges:

- Cutting-edge SLM technology: We use high-precision industrial SLM printers to produce complex geometric shapes with high-quality surface quality and material properties.

- Material Level: The deep expertise of a wide range of metal alloys ensures a perfect match that suits your project’s needs – whether it’s lightweight structural integrity, amazing aesthetics or functional performance. Most materials are customizable.

- Integration post-processing: Enjoy real one-stop convenience. From expert support for removal and heat treatment to advanced polishing, CNC machining, electroplating and custom painting – We handle all this Under strict quality control.

- Quick customization: We understand that enthusiasts and developers need agility. Greatlight provides fast turnaround times for custom machining and prototype projects at competitive prices.

- Project support: Our team provides valuable guidance on Manufacturing Design (DFM), Material Selection and Process Optimized Design for the best results.

in conclusion

3D Printing Bumblebee Characters is a meaningful project that blends fanaticism with the art of technology. Although plastic printing provides an introduction, Metal 3D printing printed with SLM technology unlocks a certain level of detail, durability and aesthetic excellence This does respect the role. Work with experienced providers Rapid prototyping Ensure you utilize advanced manufacturing, comprehensive post-processing and in-depth material knowledge. result? A premium, long-lasting bumblebee collection that captures every detail accurately and combines the feeling and feel of impressive alien engineering. Whether you are an enthusiast, artist or product developer, you have the ability to use metal 3D printing to bring your vision of this iconic Autobot to life with unparalleled quality.

FAQ: 3D Printing Metal Bumblebee

-

Is metal 3D printing enough to satisfy the image of Bumblebee?

- Absolutely. SLM printed metal parts such as Alsi10mg or 316L stainless steel are high strength and stiffness. Strategic joint designs with appropriate gaps can pronounce pronunciation long-lasting under normal treatment. Design consultation is key to complex moving parts.

-

How expensive are 3D printed metal bumblebee?

- Costs vary widely based on size, material selection, complexity and required post-treatment effects (e.g., basic blasting vs. polishing and chrome plating). The figurine starts at hundreds of dollars as a premium collectable investment, while larger complex parts cost more. Model-based specific quotes are crucial with services like Greatlime.

-

How long does the whole process take?

- Turnover depends on size, complexity and finish. Simple SLM printing can take 1-3 days; complex post-processing (such as high polish boards) adds more time. A typical project schedule for 2-6 weeks is expected to be used with professional service providers.

-

What file format should I provide?

- supply Watertight 3D Model exist .Step or .iges Format for best results, as they retain precise geometry. Common formats such as .stl are acceptable, but may require manual cleaning checks.

-

If I only have one concept, rather than a fully modeled Bumblebee, can Greatlight help me?

- Yes! Greglight provides a comprehensive service. In addition to printing, we can connect you with skilled 3D modelers or provide design feedback to ensure your concept optimizes productivity with SLM technology.

-

Is there a size limit?

- Greglight’s industrial SLM printers handle large build volumes. The specific limitations depend on the material and printer model. Large models may be divided into printable sections with engineering joinery technology.

-

Which metal alloy looks the most like the screen appearance of Bumblebee?

- Polished aluminum or electropolished stainless steel offers a bright silver color "Primer." However, the realization of iconic Yellow need Electrochrome plated on nickel/copper base Or high-performance metallic yellow paint is professionally applied to complete metal surfaces. Discuss your vision for completion with your prototype partner.

- Why choose Greatlime over other metal printing services?

- Greglight combines Advanced SLM hardware, deep materials science knowledge and internal mastery of meticulous planning technology (Including special electroplating/painting). We provide a A truly integrated one-stop solution From design advice to final inspection, ensure consistency, quality and efficiency are specifically used to require rapid prototype development tasks (such as complex collections). Get your custom project quote now!