When Fantasy Meets Reality: Bringing Star Citizen Spaceships to Industry – GSLM 3D Printing

For celebrity civic fans, charm is more than just gameplay – it is inhabited in an elaborate universe until the wear edges of every sophisticated panel, thruster nozzle and iconic spacecraft. Advanced manufacturing technology, while possessing real-life zodiac signs or arrows, remains firmly in the sci-fi world, offers the next best thing: transforming detailed digital assets into breathtaking, tangible 3D printed replicas. Input Selective Laser Melting (SLM) Metal 3D Printing – A technology that drives the possibility of bringing digital starships into the physical world, on Greatlight, is our expertise.

Why use it for interstellar citizen models? More than just appearance

Many may start with FDM printers for plastic models, but true enthusiasts, collectors and even prop manufacturers seek ultimate fidelity and durability for metals. SLM separate:

- Unparalleled details copy: Celebrity Citizenship is known for its crazy loyalty. SLM printers use fine lasers to melt metal powder layers layer by layer (down to resolution of 20-30 microns). This captures tiny details – cockpit struts, engine baffles, wear textures – plastic printers blur or simply missed. Imagine holding the M50, each landing ski detail and panel line is a razor.

- Industrial grade materials and properties: We print using certified aluminum alloys (e.g. ALSI10MG, ALSI7MG0.6), titanium (Ti6al4v), stainless steel (316L, 17-4PH), etc. This is not only for display; it translates to:

- Strength and rigidity: Unlike thin plastic parts, metal prints can withstand no warping without warping. They feel Major.

- Heat resistance: Ideal for high-definition engine components or vessels that are displayed under lighting.

- Real Metal Finish: Basic Materials yes Metal. The subsequent finishing elevates the appearance from original prints to museum works.

- No compromise complexity: SLM really comes with complex geometry. Starship models have internal lattice (for lightweight zooming "structure" Components), complex cooling channels (simulated engines) and overhanging structures (wings, weapon mounts), while traditional machining is simply not possible without multi-part components. SLM is built in a single layer.

- Scalability: While large flying boats are impractical, SLM can scale metal in metal in really meaningful scales (1:100, 1:50, and even larger key components), thus capturing the grandeur lost in tiny fragile plastic prints.

Great Advantages: From CAD Files to Display

Having detailed STL files for your favorite RSI, Drake or Anvil Creation is only the first step. Transforming it into a heirloom-quality metal replica requires expertise:

- Advanced SLM technology: We have invested in top industrial SLM machines. Precision laser scanning, controlled inert atmosphere and optimized re-finishing ensure consistency and quality of a layer. Think of applying Micron-Precision to your favorite starship.

- Materials Science Expertise: It’s not just printing; it’s about the behavior of different alloys during the melting and cooling phases. Our engineering team optimizes the parameters of each specific geometry and material to minimize internal pressure, prevent warping or cracking, and ensure structural integrity, especially for thinner functions such as sensor arrays or wingtips.

- Post-processing master: Original SLM printing is strong, but requires refining. This is where art meets science:

- Accurate support for deletion: Minimize damage to delicate surfaces.

- Heat treatment: Reduce the stress of stability.

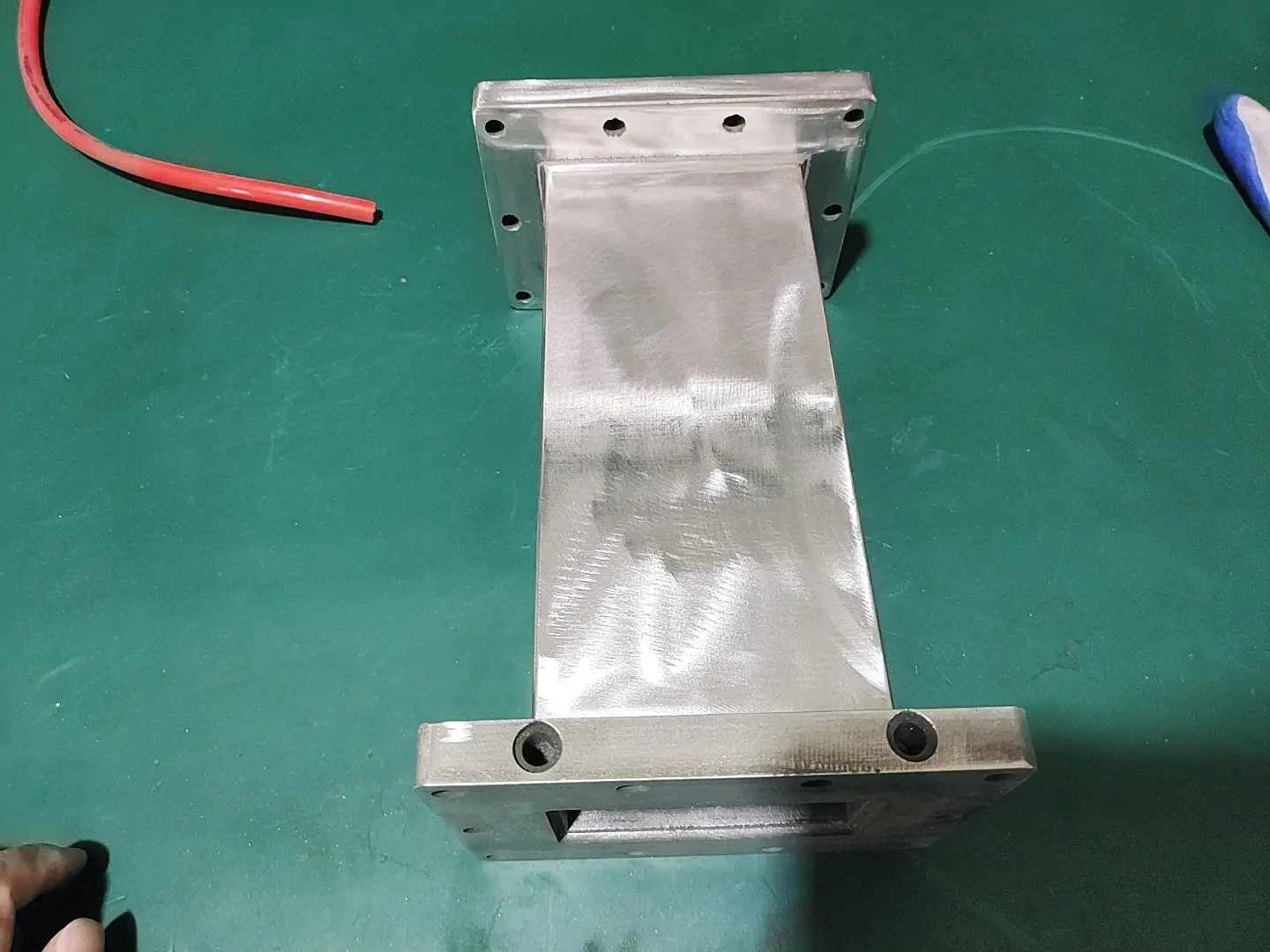

- Multi-axis CNC machining integration: For critical interface points or implementing surface finishes (such as a completely flat mounting base, precise PEG holes for assembly holes), it is not possible on the printer alone. Greglight offers seamless AM/CNC functionality under one roof.

- Surface finish: Steam polishing, for smooth aesthetics, hand polishing with mirror illuminated, matte texture of professional beads, expert start-up and iconic painted replica paintings (RSI Blues, Drake Grunge, Crusader Whites). We can also apply professional coatings such as Cerakote for extreme durability or unique effects.

- Complex components: For multi-part ship models, our technicians ensure that industrial methods are used to ensure perfect alignment and safe combination.

- Rapid Prototyping DNA: Our core business revolves around solving complex metal prototyping challenges to the aerospace, automotive and medical industries. Your star citizenship boat directly benefits from this strict problem-solving approach, requiring tight tolerances (can be completed by completing ±0.1mm) and high-quality results.

Beyond the Mantel: Functional Prototype Potential

While most fans are looking to showcase the model, the underlying technology will release more. Industrial designers or engineers working in future hardware can use the capabilities of Greatlight to quickly prototype functional scale models:

- Avionics for flight sticks or SIM card pits.

- Customized joystick grip is ergonomic.

- Durable button or switch panel.

- Complex parentheses for emulator components.

- Concept works inspired by interstellar citizen designs to explore true manufacturing feasibility.

The material properties of SLM printing make this functional exploration feasible in ways that FDM or resin printing cannot match.

Conclusion: Touch the digital boundaries

Starship in “Star Citizen” represents digital art at its peak. SLM Metal 3D printing is deployed by advanced manufacturers such as Greatlight, and it provides a technology bridge that turns these pixel-perfect assets into amazing, tangible craftsmanship. It’s a fusion of cutting-edge additive manufacturing science, meticulous finishing and pure fanaticism. result? Not only the model, but also the physical embodiment of the “scripture” carefully crafted from aviation-grade materials to focus on the details that respect the original vision. It changed the dream "Own a spaceship" Entering the breathtaking physical reality.

FAQ: 3D Printing Celebrity Citizens and Industrial SLM Technology

-

Can I really print any celebrity citizenship boat?

- Technically, yes, but complexity is important. When any ship file (if legally obtained/created) able When ready to print, viability depends largely on the resolution of the file, water density (various) and structural logic. Like the Banu Defender or Vanduul Scythe, highly complex organic ships require expert 3D model cleaning and potentially intelligent support strategies. As intensive, detailed vessels as intensive as recyclers require strong support for dismantling plans. We collaborate with our clients on document evaluation and optimization.

-

How much does a metal SLM printing boat cost (e.g., black)?

- Costs vary greatly. it depends:

- scale: Double the size of the model by more than double the material volume (cube relationship).

- Material: Aluminum alloy is the standard product, and titanium is high-quality.

- Complexity/assembly: The cost of multi-part models exceeds the overall print due to the increased printing/post-processing time of assembly labor, installation of hardware, and each section. Density and complex voids can affect printing time and material use.

- Finish: Mirror polishing or advanced painting adds the cost of basic steam blasting. As a very rough start A powerful showpiece guide: A small boat (e.g., arrow) starts at a 1:100 ratio, possibly in the range of hundreds of dollars, while a large, detailed multi-part ship (e.g., Carac) can expand to thousands of dollars.

- Costs vary greatly. it depends:

-

Plastics & Metals: Is SLM worth it?

- For ultimate loyalty, realism and lifespan: Absolute.

- Plastic (FDM/resin): Lower cost, faster, perfect for Early Prototype or lightweight display. Distortion, loss of detail of thin features, vulnerability (snapshot risk), plastic feel and limited temperature resistance. Layer lines are usually visible.

- Metal (SLM): Capturing the microscopic tail has excellent strength/rigidity, it feels like a real tool/object, heat resistance, and the base is conductive metal. Offers unrivaled aesthetics and offers professional finishes. No layered lines with steam polish/paint. Ideal "The final" High-end display, prototyping of functional components or durable collections. ((For example: The ALSI10MG printed model has practical mechanical properties comparable to that of cast aluminum. )

-

I have STL. What’s next?

- Contact Greatlight Prototyping. Our process involves:

- consult: Discuss your model, the size required, preferred materials, finish levels and budget.

- Document analysis and preparation: Our engineers analyzed the printability of STL, identified potential issues and performed any necessary structural analysis or optimization (critical wall thickening, optimized support anchors, logically separating parts when needed).

- Quote: We provide detailed quotes based on final specifications.

- Print, post-process and organize: After approval, we leverage the SLM fleet, then the skilled finishing department.

- Strict inspection and delivery: Please inspect parts according to quality standards before safe transportation.

- Contact Greatlight Prototyping. Our process involves:

-

What is a realistic timeline?

- Additive manufacturing is not instant magic.

- Project Complexity: Small-scale simple, solid model: possible 1-2 weeks. Large, complex multi-part models require complex sorting: 4+ weeks is common. File analysis/preparation and post-processing are important parts.

- Realistic expectations: allow At least 3-6 weeks From the final specifications/down payments to the delivery of the most important high-quality models, there is no excellent queue situation.

-

How strong are these metal models? Can it be handled?

- Very strong compared to plastic! SLM metal components have good structural integrity. Aluminum alloys like AlSI10 mg have high yield strength. They should have been dealt with carefuljust like an accurate scale model. them able Drops and may dent or break thin protrusions (such as antennae), unlike plastic that may break. Avoid too much power. They are Displaynot toys.

-

Can you print in huge sizes (e.g. 1 meter)?

- Yes, considering:

- Machine Envelope: We have large SLM machines that can have a considerable build volume. But, Single Printing runs is determined by a specific machine.

- part: Vessels exceeding the machine are professionally divided into printable sections, which are then assembled and processed (using industrial bonding techniques, keying and potential internal structural components).

- Cost and weight: Large-scale increases material costs, printing time, post-processing time, completion cost and final weight.

- Structural integrity: Very large thin-walled structures require careful design analysis to ensure that they do not sag during printing or processing and support their weight. Supporting strategies becomes crucial.

- Yes, considering:

-

Can my boat design be legally safe to print?

- Gremphime prioritizes compliance. We ask customers to confirm that they have the legal right to copy the 3D model files they provide. This usually means:

- Create original derivative models based on publicly available schematics or game files Personal use only (usually non-commercial fair use/fan art).

- I own the original CAD design.

- Get explicit permission from the original artist who is Cloud Empire Game (CIG) or commercial breeding. We cannot produce unauthorized commercial resale items that come from copyrighted celebrity citizen assets.

- Gremphime prioritizes compliance. We ask customers to confirm that they have the legal right to copy the 3D model files they provide. This usually means:

-

What file format do you need?

- STL is a universal standard. Make sure that is:

- water proof/"Manifold" (There is no hole/gap in the grid).

- The solution is suitable (high enough poly count to capture details without being inefficient).

- It is best to export in correctly defined units (mm).

- Complex components may require separate STL files for each part as well as an assembly guide.

- STL is a universal standard. Make sure that is:

- Can Greatlight help if I don’t have a good model file?

- Our core expertise is manufacturingnot model creation/RIP extraction. For complex procurement of complex celebrity citizen ship models, you may need to interact with skilled 3D artists familiar with game assets to create or adjust available production files. Then we can handle manufacturing excellence. We can provide suggestions on the required file characteristics.

Ready to see your favorite celebrity citizenship boat crossing the digital divide? Put your vision for high-fidelity metal replicas to make prototypes. Leverage our industrial SLM printing abilities and mastery to create truly special poetry for your collection or project. [CTA – e.g., Contact us for a quote today, Explore our capabilities].