The ultimate DIY guide to 3D printing custom Crocs charms: from design to wearable art

Crocs are more than just comfortable shoes, they’re a blank canvas for self-expression. While store-bought Jibbitz™ charms are fun, 3D printing your own charms allows you to unleash your creativity. In this guide, we’ll walk you through the design, printing and finishing of a custom Crocs charm, providing expert tips for achieving the perfect result.

Why 3D print your own charm?

- unique personalization: Turn a joke, favorite animal, or pop culture icon into a wearable piece of art.

- Cost effective: Print dozens of charms at retail package prices.

- Iterate quickly: Test designs in hours, not weeks.

Step 1: Design Essentials – Combination of Geometry and Function

Key specifications:

- Aperture: Standard Crocs hole diameter is 4.7–5.0mm. Make sure your charm’s hooks fit snugly and won’t break. design nails located at 5mm Has a slight taper.

- size limit: The ideal charm size is 15–20 mm width/height to avoid bulkiness.

- Durability: Avoid fragile overhangs (such as thin antennas). Use reinforcing materials such as fillets or ribs.

Software recommendation:

- beginner:Tinkercad – Drag and drop shapes using the simple hole tool.

- advanced: Fusion 360 or Blender – for creating intricate details.

For tips:Export the design as .STL files Optimized for slicing.

Step Two: Material Selection – Balance of Beauty and Strength

Choose materials based on use:

- People’s Liberation Army: Bright colors and easy to print (ideal for decorative charm).

- Peteg: Flexible and UV resistant (high impact charm perfect for kids).

- Resin (SLA): Ultra-fine detail – requires post-cure UV hardening.

Safety precautions: Use skin-safe, non-toxic filaments. Avoid prolonged contact with ABS.

Step 3: Printing techniques to create the perfect pendant

Printer settings:

- Floor height: Smooth surface is 0.1–0.15mm.

- filling: 15–20% (hexagonal pattern).

- support: Suitable for designs with overhang >45°.

- brim/raft: Prevent small prints from deforming.

Common pitfalls:

- Threading: Reduces nozzle temperature and enables retraction.

- weak hook: Print vertically for better layer adhesion.

Step 4: Post-processing – from rough printing to polished stones

- Remove supports: Cut carefully; use flat end mill.

- Sanding: Start with 120 mesh sand and finish with 400 mesh sand to get a smooth base.

- start up: Spray filler primer to hide layer lines.

- painting: Use acrylic paint or enamel paint. For sealing Varnish For waterproofing.

- coating: Food grade epoxy resin for added gloss and durability.

Step 5: Work with a professional for impeccable results

For those who require industrial-grade precision or specialty materials such as flexible TPU or nylon, working with a rapid prototyping expert ensures longevity and polish.

Why choose Gretel?

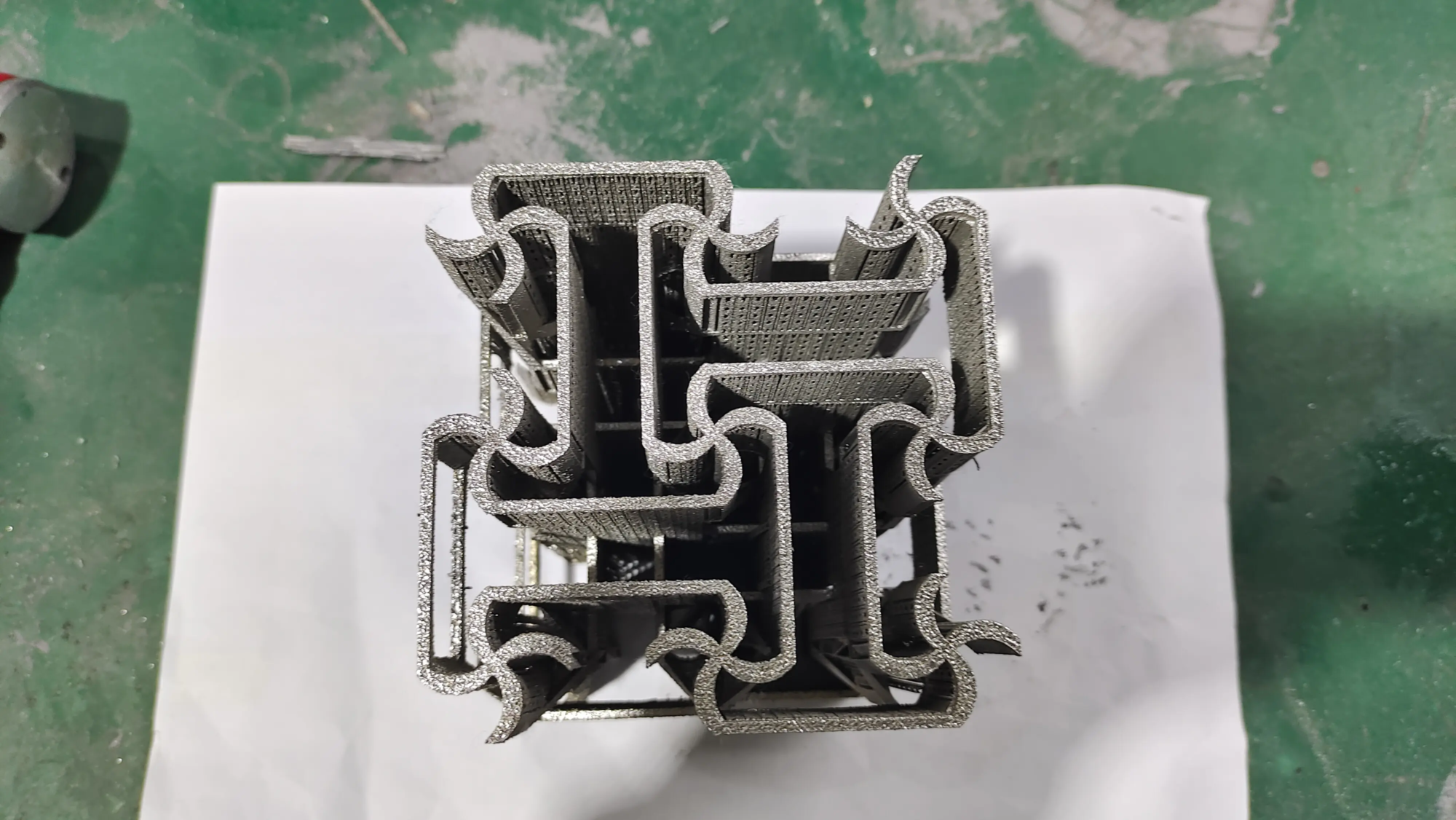

- industrial SLM 3D printer Metal/Plastic Unparalleled Detail.

- One-stop post-processing: Sand blasted, stained, steam smoothed and sealed.

- Instant quotes and quick turnaround: Upload your design online to get a same-day prototyping quote.

GreatLight specializes in medical/dental grade prototyping, ensuring non-toxic, child-safe finishes, perfect for wearable accessories. Their end-to-end service transforms concepts into resilient, jaw-dropping charm.

in conclusion

3D printed Crocs charms blend creativity and technology, allowing you to design accessories that are as unique as your personality. Whether you’re a DIY enthusiast making charms on a desktop printer or working with pioneers like GreatLight to create aviation-grade nylon charms, this guide can help you revolutionize your footwear game. Start Printing – Enter a world where every charm tells your story.

FAQ

Q1: Will PLA amulets melt in hot weather?

PLA softens at around 60°C. For hot climates, use PETG (85°C) or outsource to GreatLight for weather-resistant nylon.

Question 2: How to secure the ornaments firmly?

After inserting the nail, add a point UV resin or E6000 glue Reserved permanently.

Q3: Can I use metal to make pendants?

Yes! GreatLight’s SLM printers can handle stainless steel, aluminum, and titanium—perfect for producing heirloom-quality pieces.

Q4: Are 3D printed ornaments safe for children?

Use only non-toxic, certified materials. Professionally finished components seal pores and minimize the risk of bacteria.

Q5: What is the cost difference between DIY and professional printing?

DIY charms cost pennies per gram (for example, PLA is $0.20). Outsourcing intricate designs averages $1-5 per charm, but the quality and durability are outstanding.

Q6: How thin can I print the ornament details?

Desktop FDM: 1 mm minimum. Industrial SLA/SLM: 0.25 mm max.

Transform ordinary Crocs into a personal gallery – get creative with a 3D printer, or tap GreatLight’s expertise to create exquisite, production-ready works of art.