Embrace personalized organizations: a revolutionary journey of 3D printing custom remote controls

Life in the digital age means fighting a chaotic coffee table. TVs, sound systems, streaming devices, remote controls for gaming consoles – they multiply, slide, and disappear into the abyss of the sofa. General holders often fail and end up being too small, unstable or visually stinging. This is the real power Additive Manufacturingspecial 3D printingShining: Authorizes you to create Perfect Solution – a Custom remote control Fully tailored to your needs and space.

Ready-made weaknesses and the strength of customs

Universal remote holders suffer from inherent flaws:

- this "One size does not fit" Dilemma: Remote remote size, shape and weight vary greatly. Slim streaming with thick universal folding sum. A holder designed for one rarely accommodates another well.

- Aesthetics disconnected: Finding a holder who matches your decor, color scheme, or personal taste is often a frustrating compromise.

- Space constraints: Unique furniture shapes, narrow side tables or specific wall placement require holders to have precise dimensions and installation styles, and mass-produced options are rarely available.

- Durability issues: Cheap plastic brackets cracked; fragile design tips. Your expensive remote should be better protected.

3D Printing: Unlocking unprecedented customization

3D printing technology directly solves these limitations:

- Perfect dimension matching: Using simple measurement or even 3D scanning remote control, you design (or commissioned design) holders with slots Exactly Match each device. No swing, no mandatory – a caring, safe home for every remote.

- Design free release: Express your personality! Create holders shaped like your favorite characters, inspired by nature, seamlessly integrate into the minimalist aesthetic of the room, or take advantage of the brand theme. Flowing curves, intricate geometry, personalized text prints – only your imagination can set the boundaries. Software like Tinkercad, Fusion 360 or Blender empowers this creativity.

- Accuracy is suitable for unique spaces: Need a custom stand to clip on an uneven table? Do you need a specific inclination angle? Want a holder between books that are fixed to the shelf? 3D modeling and printing make it possible to achieve with millimeter accuracy.

- Materials Science you serve: The choice of materials greatly affects function and aesthetics. Do you need a stable and solid foundation? Choose to have wire or consider professional Metal 3D printing service From experts like Great. Need a feeling of resistance and luxury? Nylon or high-quality PET may be enough. Want the impact resistance of a busy family? A TPU (flexible filament) or a robust ABS may be ideal. Material selection is an integral part of design success.

- Iteration perfect: A holder was designed but found that the remote still swings a little? 3D printing allows for fast, cost-effective iteration. Easily adjust the design files and reprint them for implementation Perfect Result – Agility that cannot be possible in traditional manufacturing.

From idea to reality: Workflow to make holders

Here is the roadmap for your remote control project:

-

Definition requirements:

- Measure all your remote controls (LXWXH, including unique protrusions like wristbands).

- Determine the capacity (3 remotes? 5?).

- Select a location (table, wall-mounted, fixed sofa arms?).

- Determine the preferred style/aesthetics and necessary material properties (weight, feel, durability, color).

-

Design creation:

- DIY route: Learn about beginner-friendly CAD software. Start with basic geometry to form slots and bases. Many tutorials and open source designs can be tweaked.

- Debugging route: Work with professional designers or use them by Professional rapid prototype manufacturer. Utilize their expertise to turn your vision into an optimized, printable model that ensures structural integrity and printability.

-

Material selection:

- Consumer FDM/FFF printers: PLA (biodegradable, easy), PETG (durable, chemical resistant), ABS (hard, ventilation required), TPU (flexible).

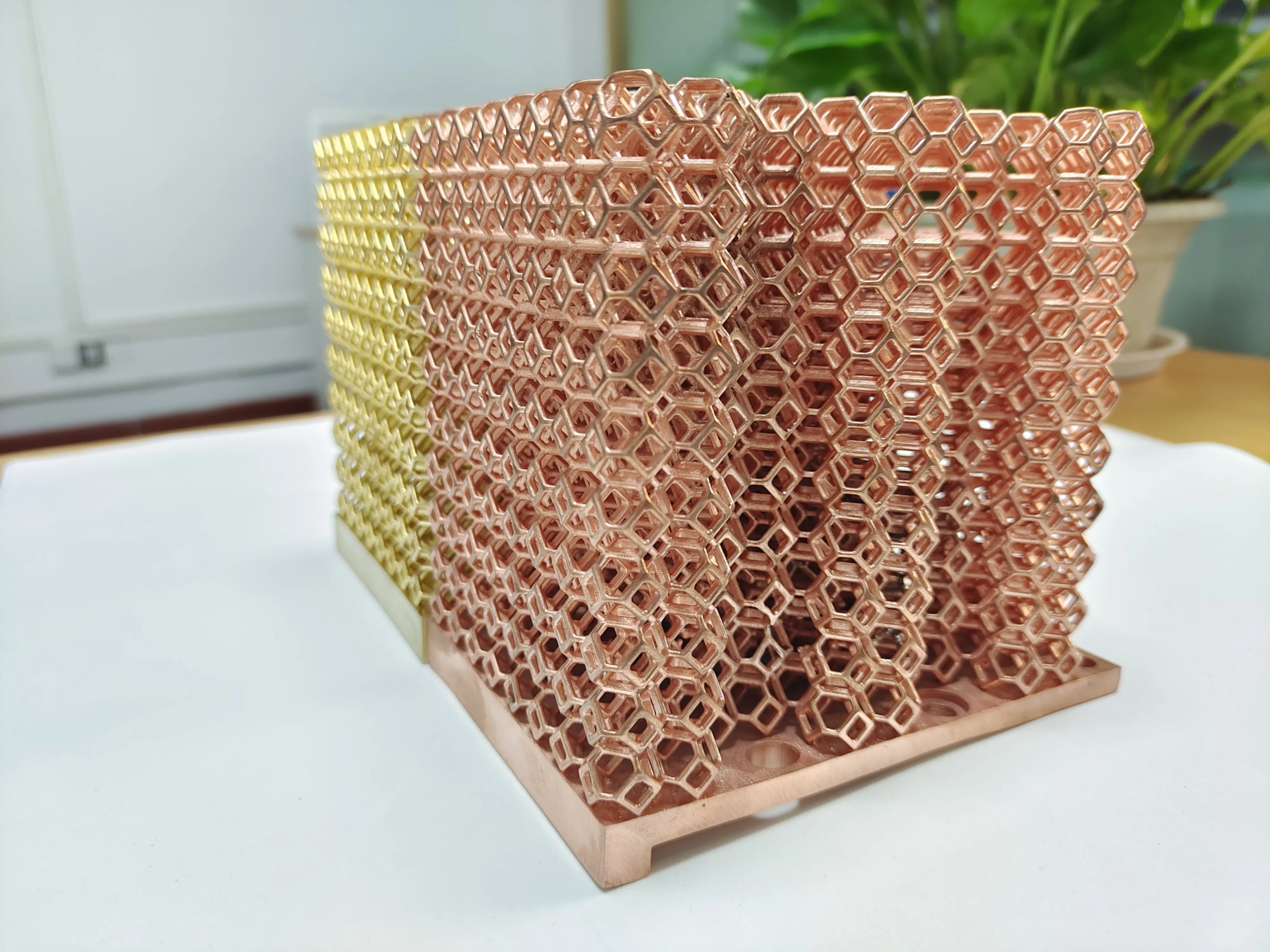

- Professional Services (SLA, SLS, Metal): The resin details incredible details and smooth finishes, high strength and flexibility of nylon powder, or Metal selection (aluminum, titanium, stainless steel) for maximum durability, weight and quality look/feel. Gremight is good at all in these advanced processes Selective laser melting (SLM) of reliable metal parts. **

-

Printing and post-processing:

- consumer: Print on your machine. Careful calibration is required (bed adhesion, temperature). Post-treatment may involve removing support materials, polishing and painting/tidying.

- Professional: Upload your design files to the service provider Great. The complexity of their printing process they use Advanced equipment and production technology. Crucially, they provide One-stop post-processing and completion – Professionally remove support, achieve the required surface smoothness (sanding, blasting), apply skateboard coating, and even electroplated metal parts. This converts the original print into a professional-grade, user-ready product.

- implement: Enjoy the clutter-free space! Install your holder or place it proudly to show off a functional personalized design.

Why collaborate with advanced solutions?

Although desktop printing is suitable for simple plastic holders, complex designs requiring high strength, precision, specific aesthetics (such as metals) or unique material properties benefit greatly from professional services. Greglight is the leading rapid prototyping manufacturerspecifically solve the requirements Problems with rapid production of metal parts.

- Technical strength: invest Advanced SLM 3D printer And other cutting-edge technologies (SLA, SLS) ensure that functions are far beyond consumer machines.

- Material expertise: They handle one A wide range of materialsfrom engineering plastic to robust Metalprovides a guide to choosing the best choice for the remote control function and the desired feeling.

- End-to-end service: Greglight provides a true one-stop solution: Technical consultation, design optimization, Precise processing (If mixing parts are required), Comprehensive post-processingand Quality Assurance – Eliminates the hassle of managing multiple suppliers.

- Customization and speed: Most materials can be customized and processedmeet unique design needs and accelerate your product development or personal project schedule.

- Eat voucher: Their reputation One of the best rapid prototyping companies from China Built on delivery Custom precision machining and prototypes that meet stringent quality and reliability standards. They have Professional, Authoritative and Trusted (EAT) Crucial for complex or mission-critical components, naturally scaling to achieve perfect results for advanced remote holders, such as advanced remote holders.

in conclusion

3D printing custom remote holders go beyond organizations; it represents the democratization of manufacturing. It enables you to replace compromise with a perfect solution designed with precise design your Life. Whether you are on a DIY journey or leveraging the expertise of a professional prototype partner Greatthe ability to transform personal requirements into tangible, functional and aesthetic objects embodies the transformative power of additive manufacturing. So measure your remote, unleash your creativity, enter the future where debris disappears, and securely secured by works that are designed entirely by you. Great Ready to turn your unique vision into a polished, durable reality – Customize your precision fast prototyping parts now at the best prices!

FAQ: 3D Print Your Custom Remote Control

Question 1: I don’t have design skills. Can I still get a custom holder?

Answer: Absolutely! You can find open source designs online that may be close to your needs and slightly modify them. More convenient, Professional rapid prototyping services (such as Greatlight) often provide design assistance or complete design services. Give them your requirements and remote sizes, they can create optimized CAD models for you.

Question 2: Is it cheaper to buy a universal holder or 3D printing custom?

A: Simple PLA holders print at home able Very cost-effective for basic designs. However, professional printing services become necessary and added for complex shapes, large sizes, or when using high-quality materials, especially metals. Considered values: Perfect Suitable, durable, aesthetically pleasing long-term solution for your specific remote and decoration, it can often justify an investment in multiple universal alternatives.

Q3: What are the advantages of using metal 3D printing brackets?

one: Metal 3D printing (such as SLM provided by Greatlight) Provides significant benefits for remote holders:

- Excellent weight and stability: Even with a heavy remote, it is unlikely to overturn.

- Excellent durability: High resistance to drops, impacts and wear.

- Advanced Aesthetics: Offers a unique high-end metal look and feel.

- Heat resistance: Suitable for environments near heat sources.

- Complex, strong geometric shapes: Traditional metalworking makes design difficult or impossible.

Question 4: How long does it take to get a custom holder for professional printing?

A: The time range varies significantly, depending on complexity and provider. Simple plastic parts for basic services can take several days. for Precision metal prototyping and complex finishesexpect a process to be usually used One to a few weeksincluding design (if needed), printing and thorough Post-processing and completion Ensure high quality. They focus on Rapidly Solution without compromising accuracy.

Q5: What file format is required for professional 3D printing?

Answer: The most commonly accepted and recommended format is STL (standard mosaic language). Some services may also be accepted OBJ or native CAD format (such as step). Always check the specific requirements of the selected manufacturer. Make sure your model is watertight (multiple) and scales correctly before committing.

Question 6: Can I get features like non-slip lining or engraving?

Answer: Yes! This is Professional post-processing shines. Like from Great It may include adding skateboard paint or mats inside the base and slots. Engraving (logo, text, pattern) can usually be incorporated directly into the design file and printed/manufactured in the parts, or added post-printing through techniques such as laser marking (such as metal). Discuss your specific requirements when requesting a quote.