Perfect production: Basic design tips for 3D printing cylinders

Cylinders are a fundamental component of countless industries – from hydraulic systems and engines to custom actuators and precision instruments. However, successful printing of them, especially in metals, requires careful consideration of the manufacturing process. At Greatlight, we use advanced SLM (Selective Laser Melting) technology every day to produce high-performance metal cylinders for demanding applications. This is our internal view on optimizing the successful cylinder design of 3D printing.

1. Master the direction: Building the direction is the most important

The angle of cylinder printing is significant:

- Surface quality: Horizontal cylinders need support. Although the surface provided by the SLM is smoother than some processes, points that support contacting the cylinder surface (especially on the bottom surface) will require post-processing. For the smoothest exterior and inner walls, the goal is vertical.

- Mechanical strength: Parts printed by SLM have anisotropic properties. Layers built perpendicular to their main stress direction are usually weaker. For cylinders facing internal pressure or axial load, print vertical Ensure that the layer line runs circulating and aligns better with the hoop stress, thereby increasing the burst pressure.

- Support for minimization: Vertical printing greatly reduces the need for complex internal support structures within the hole. This saves material, reduces printing time, simplifies post-processing, and minimizes the risk of internal surface defects.

2. Wall Thickness: Balanced Strength, Details and Process Limitations

Avoiding failures requires respect for materials and process capabilities:

- Minimum: SLM can reach impressive thin walls, usually 0.3-0.5mm For solid metals, such as stainless steel 316L or aluminum ALSI 10mg. However, designing absolute During support removal, minimal risk of pinholes, twisting or handling damage. Target At least 0.8-1.0mm Used for reliable printing of complex geometric shapes.

- Unification and Transition: The sudden transition from thick to thin creates stress concentrations and increases the risk of distortion. Use progressively changing progressive rounded corners or tapers. It is designed to keep the surrounding wall thickness consistent to allow it to cool evenly.

- Hollow cylinder: Essential for lightweight or fluid carrier applications. Make sure the walls are thick enough to withstand internal pressure (or vacuum) and any planned post-treatment, such as grinding or chemical smoothing. Remember internal support to eliminate complexity – it is usually best to minimize by orientation.

3. Internal function: design core

Cylinder bores are essential for function.

- Smooth hole design: For pure, non-textured sliding surfaces, vertical printing is usually the best. Specify the required surface roughness (RA) so that completion (grinding, polishing, electropolishing) can be planned accordingly.

- Internal channels and ports: Integrate fluid ports directly into cylinder walls? Avoid intersecting with the sharp 90 degrees of hole. Use Chamfers or circular transitions. If the port is close to the end, an escape path for the trapped powder is designed. Consider the printing direction to minimize support within the fluid path.

- Internal thread: Avoid thin lines. For M6 and below, design test holes and click-through prints for maximum thread integrity. For larger internal threads, consider printing them vertically with a dedicated support strategy – it is crucial to rigorous testing of features. Automatic tapping of inserts or helices is often superior to critical components.

4. Achievement accuracy: tolerance and fit

Don’t expect "first aid" Perfect for mating surface:

- Shrinkage allowance: The metal parts shrink slightly during cooling. Printed file scaling (usually uneven scaling coefficients are applied depending on the direction/direction) in experienced manufacturers (such as the Greatlight factor alloy specific shrinkage rate). Clearly provide your key dimensions and tolerances.

- Key Diameters and Finishes: If your cylinder fits together with the piston, bearing, or sealing ring, the holes may need to be accurately processed and printed. Specify

+/- 0.1mm(More fixed in the specified case) Tolerance bands on these critical IDs and ODs and allow processing stock (e.g., 0.25-0.5mm radial additional material). - Thermal management creep: Make sure that nearby parts do not generate too much heat during printing, resulting in differential shrinkage and local deformation around the mating surface. Thermal simulation analysis can help prevent this.

5. Utilize post-processing capabilities

SLM provides you with complex geometry; post-processing provides you with functionality.

- Processing: Sealed surfaces, high precision diameter, thread accuracy or necessary to achieve a specific roughness. Plan it in design tolerance and material allowance.

- Support removal: The design access point is effectively removed. The horizontal pore structure greatly facilitates internal support extraction.

- Surface reinforcement: Cylinders used for hydraulic or pneumatic require smooth hole finishes. Specify requirements – Honing (e.g. CH or RH), polishing, electropolishing? Greatlight’s one-stop service ensures the right sequences are applicable to seal integrity and low coefficient of friction.

- Heat treatment and hips: Complex metal printing usually requires stress relief. For critical cylinders (hydraulic/pressure vessels), thermal isostatic pressure (hook joint) significantly improves density and fatigue life by eliminating internal voids.

6. Material Important: Choose Alloy

Basic material selection defines the performance:

- Stainless Steel 316L: Excellent all-round player: strong, corrosion-resistant, good toughness. Ideal for many hydraulic, pneumatic, medical and marine applications.

- Aluminum alloy (ALSI10MG, ScalMalloy): Lightweight, good thermal conductivity, decent strength to weight ratio. Ideal for weight-sensitive cylinders in racing or aerospace components.

- Titanium alloy (TI6AL4V): Final strength to weight, biocompatibility, excellent corrosion resistance. Ideal for high-performance applications, aerospace and medical implants.

- Tool Steel (H13, Maraging Steel): Used for high-coat, high-strength high-temperature applications such as complex molds or molds.

- Copper alloy: Used for optimized thermal or electrical conductivity. Work closely with manufacturers on printing parameters.

Conclusion: Precision cylinder requires professional knowledge

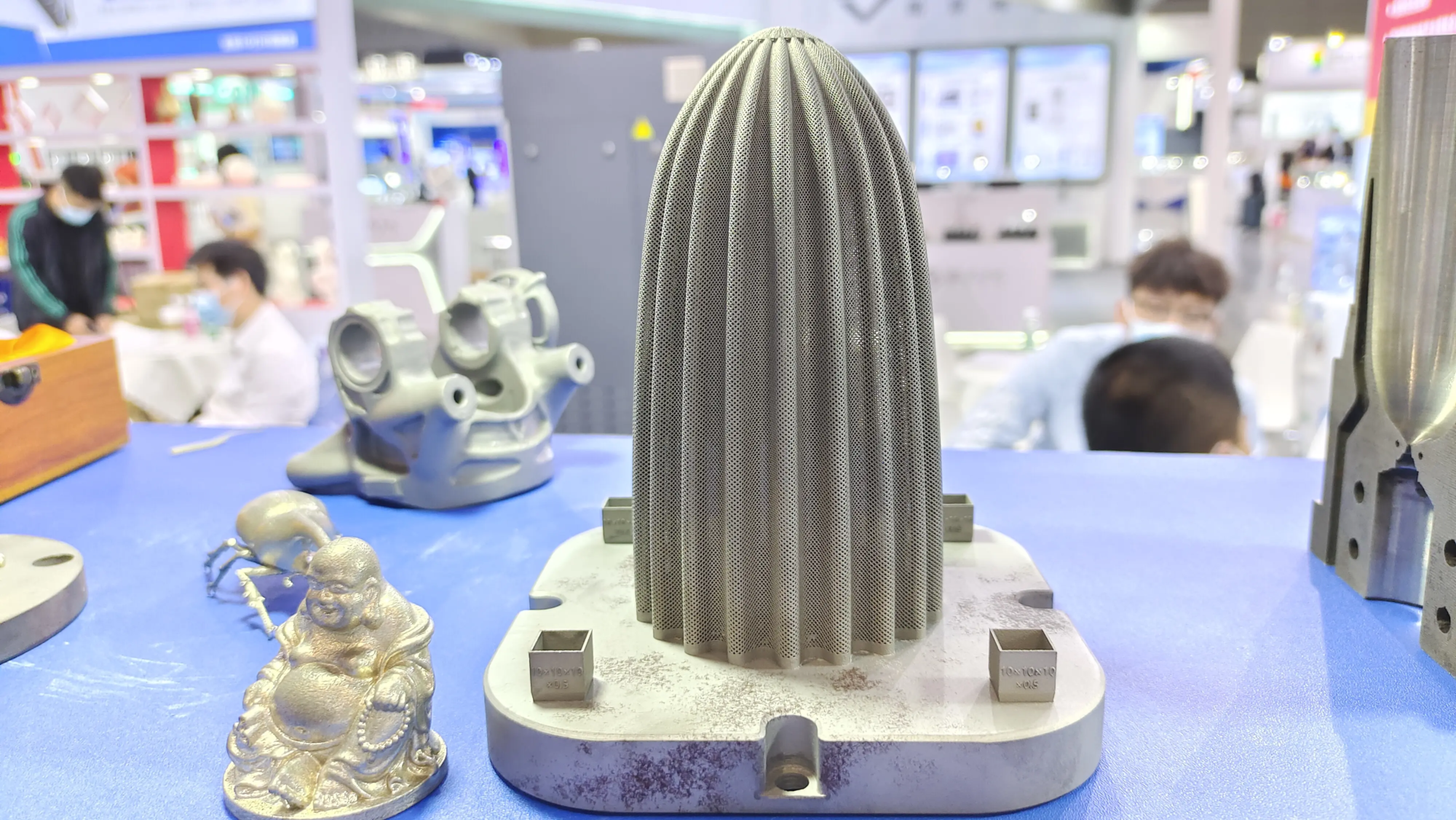

3D printed cylinder unlocks unprecedented design freedom – weight reduction, conformal cooling channels or a consolidated internal lattice assembled. However, the transition from CAD models to functionally reliable cylinders requires in-depth understanding of SLM processes, material behavior, and filling techniques.

At Greatlight, our expertise happens to be here. With cutting-edge SLM printers, deep experience in metal powder metallurgy, and comprehensive in-house post-processing capabilities including precision CNC machining, honing and advanced surface treatments, we specialize in transforming complex cylindrical designs into high-performance, stress-critical reality. We understand how directions, wall transitions, support strategies and completion choices relate to each other to ensure your 3D printed cylinder meets stringent functional requirements.

Stop falling in the cylindrical performance limits of traditional manufacturing. The potential of using additive manufacturing – Contact Greatlight now. Get excellent quality and fast turnaround at a competitive speed.

FAQ: 3D printed cylinder

Q1: What are the biggest advantages of 3D printing metal cylinders and traditional methods?

Answer: The key advantage is Free design (Complex internal geometry, integrated features such as cooling channels or fluid ports, cannot be milled/drilled), Weight loss (lattice structure inside a hollow cylinder), merge (Print the component as a single part) and Prototyping speed/low volume Production of highly complex designs.

Q2: Can I 3D print a cylinder with smooth holes directly, prepare the piston seal?

A: Very rarely possible "first aid" with SLM. Although the surface quality continues to improve, mating surfaces such as cylinder holes usually require After surgery (such as honing or fine boredom), to achieve effective, long-lasting piston sealing performance and precise tolerances (diameter, roundness, surface roughness) required for low friction.

Q3: How accurate is the cylinder 3D printed in SLM? What tolerances can I expect?

A: Standard SLM printing usually implements tolerances around +/- 0.1% Size (minimum feature dependency) or approximately ISO 2768 medium (M). For critical functional surfaces, such as hole ID or mating hole ID or mating OD, +/- 0.05mm Or usually needs to be more detailed. this need Designate processing allowances in the design and utilize professional post-processing (CNC machining/hardging). Always consult your manufacturer about key dimensions.

Question 4: Greatligh mentions SLM – Does this work for all cylindrical projects?

A: SLM is very suitable for complexity and completely dense Metal The cylinder requires strength and detailed characteristics. For simple plastic prototype cylinders that lack structural requirements, SLS or even FDM may be sufficient. Greatligh’s focus is on SLM, especially because we provide industrial-grade structural integrity surface finish control for functional metal parts. Hybrid manufacturing (printing near mesh and then processing) while tailoring precise economic benefits around workpiece features – why are you waiting for discussion now?

Q5: How do you deal with internal support in deep, narrow cylindrical holes?

A: This is challenging, but manageable! We adopt technology including strategy Printing direction (Usually vertical is best), Optimized support structure Designed for easier disengagement or machining, integration Drainage hole During design for fluidized media blasting or chemical removal, and specialized manipulators utilized extracting residues accurately following detachment procedures leveraging precision probing systems avoiding scratches contain-environment clean-out – once recognized needing specialist precision over domestic tools plus all waste disposal/recyclizing phases integrated onsite certified compliant processes firmly implemented.

Let Greatlight handle complexity so your cylinders perform perfectly – Contact us today to explore the feasibility of your project’s custom pricing packages, deliver unrivaled expertise, and consistently deliver timely contract arrangements.