As a professional rapid prototyping manufacturer, Greatlight has been at the forefront of providing high-quality 3D printing services to customers in various industries. With Advanced SLM 3D printer equipment and production technology, Greatlight specializes in solving rapid prototyping problems of metal parts and provides one-stop post-processing and completion services. In this article, we will dig into the world of 3D printing design techniques, highlighting the basic considerations for ensuring successful printing results.

Understand 3D printing technology

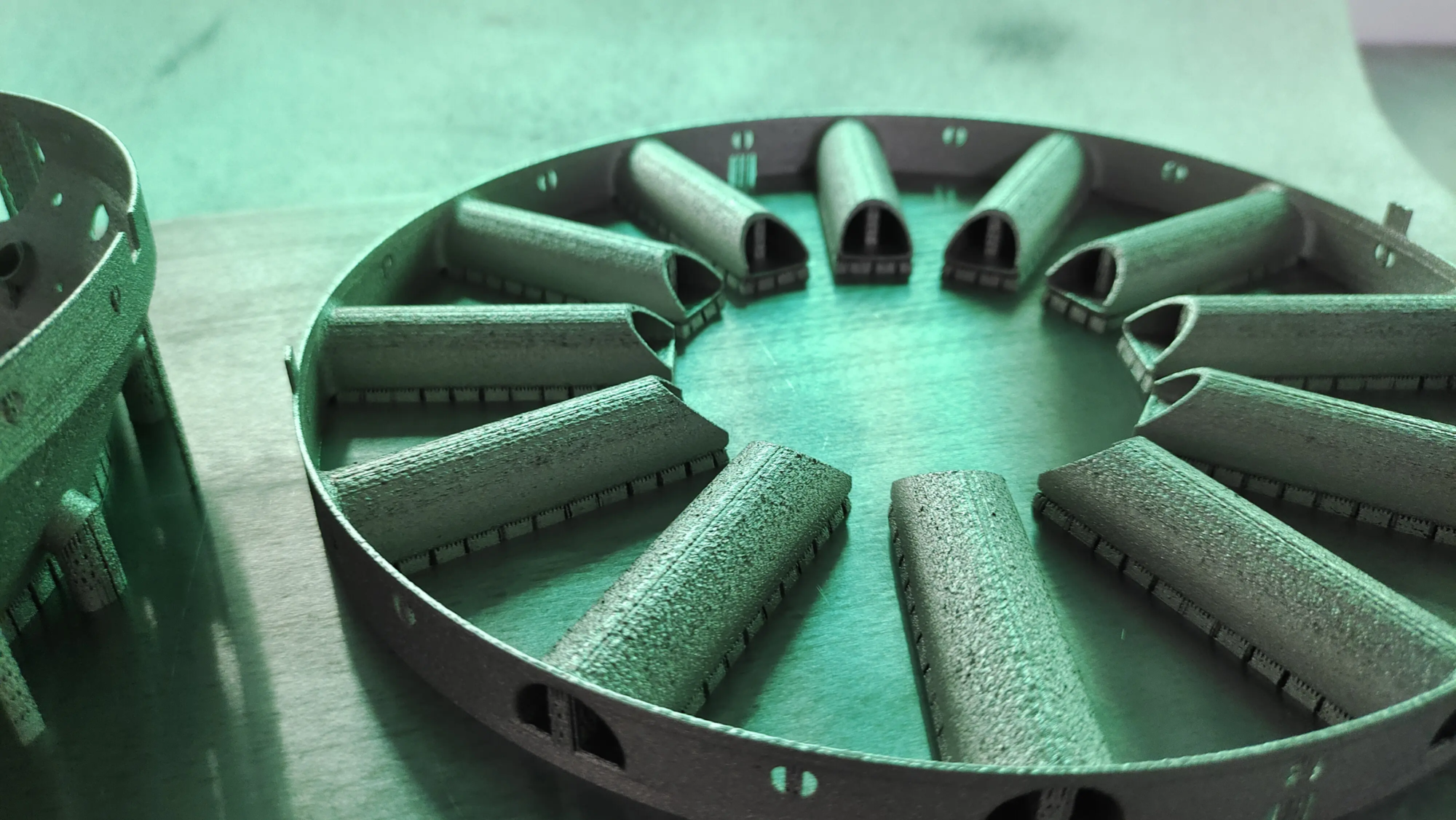

Before digging into design techniques, it is crucial to understand the different 3D printing techniques available. Greatlight utilizes selective laser melting (SLM) technology, which is ideal for producing complex metal parts with high accuracy and accuracy. SLM technology involves using high-power lasers to melt layer by layer and fuse metal powders to create the desired shape. The technology provides excellent mechanical properties, making it suitable for a wide range of applications, including the aerospace, automotive and medical industries.

3D printing design considerations

When designing 3D printed parts, several factors must be considered to ensure successful printing of the results. Here are some basic design considerations:

- Thick wall: The minimum wall thickness will depend on the material used and the intended application. Generally, for metal parts, a wall thickness of at least 1-2 mm is recommended.

- Dangling and support: Overhangs can be a challenge in 3D printing as they need to support structures to prevent them from collapsing. Designers should aim to minimize overhanging or use support structures that can be easily removed after printing.

- Hole and pocket design: The holes and pockets should be designed with draft angles to facilitate easy removal of the support structure and prevent powder from getting trapped.

- Surface finish: The finish of the printed parts will depend on the materials used and the printing technology. Designers should consider the intended application and specify the required surface surface.

- Assembly and tolerance: When designing parts that need to be assembled, designers should consider the tolerances and clearances required for smooth assembly.

Optimize the design of 3D printing

To optimize the design of 3D printing, designers should consider the following strategies:

- Topology optimization: Topological optimization involves the use of software to optimize the internal structure of a part to minimize material usage while maintaining its functional requirements.

- Lattice structure: Lattice structure can be used to reduce material usage while maintaining the strength and stiffness of the parts.

- Hollow: Hollow parts can help reduce material use and weight, but designers should ensure that the parts are maintained with structural integrity.

in conclusion

In short, successful 3D printing results depend on in-depth understanding of the design requirements and limitations of the technology. By considering factors such as wall thickness, overhang, hole and pocket design, surface finish, and assembly and tolerance, designers can create optimized designs to take advantage of the capabilities of 3D printing. At Greatlight, our team of experts is dedicated to helping customers design and print high-quality parts that meet their specific needs. Whether you are looking for custom precision machining or rapid prototyping services, we invite you to explore our features and discover how we can help you bring your designs to life.

FAQs (FAQs)

Q: What is the minimum wall thickness required for metal 3D printing?

A: The minimum wall thickness will depend on the material used and the intended application, but generally a wall thickness of at least 1-2 mm is recommended.

Q: Can I use 3D printing to produce parts?

A: Yes, 3D printing can be used to produce parts, especially for complex geometric shapes or low-volume production operations.

Q: What is the difference between SLM and other 3D printing technologies?

A: SLM technology uses high-power lasers to melt and fuse metal powder layer by layer to create the desired shape. Other 3D printing techniques, such as FDM or SLA, use different materials and printing processes.

Q: Can Greatlight provide post-processing and completion services?

A: Yes, Greglight offers a one-stop after-processing and finishing service, including machining, grinding and polishing to ensure your parts meet your specific requirements.