Unleashing Perfection: The Final Guide to 3D Printing Dice Towers (From Prototyping to Production)

Dice tower. Those random elegant guardians transform the crazy rolling ceremony into rituals. They are functional works of art that are crucial to level competition and are increasingly icons on desktops around the world. For gamers, designers and manufacturers, 3D printing offers unparalleled freedom to create custom dice towers – from initial concepts to high-performance production units. This guide delves into the process, considerations and choices to bring your ability to bring the perfect dice tower vision to life.

Why 3D printing dice towers? Advantages have been expanded

- Unrivaled customization: Get rid of universal design! The singta reflects your RPG character, game theme or unique aesthetics. Integrated logos, intricate patterns, and even functional elements such as integrated trays or storage. The design is indeed your own.

- Complex geometric shapes make the truth: Printing the internal baffle for optimizing the random dice rolls is impossible or expensive for traditional manufacturing. Create seamless organic shapes, lattice structures and interlocking components.

- Quick Prototyping Perfect: Test, iterate, perfect! 3D printing can produce prototypes quickly before promising expensive molds or mass production. Improve the baffle angle, interior layout, exit ramps and overall profile with minimal waste and maximum speed.

- Low volume cost-effectiveness: Equip a small game group? Create a custom match? Run Kickstarter? 3D printing, especially for one-time or small batch printing, eliminates mold costs and minimizes initial investment. Material cost becomes the main variable.

- Material versatility: Select attributes that match your needs. Durable PLA or PET for daily protection? Impact-resistant ABS or nylon for reuse or travel? Elegant resins get amazing details? Even exploring high-end clothing Metal alloy The final heirloom? (We’ll touch the metal more later!).

- Personal satisfaction: Design and make your gaming accessories layer by layer satisfying.

Your path to the perfect 3D printed dice tower

-

Conceptualization and design:

- Functions first: Define the core purpose. Is it purely functional? Display piece? Portable? Does it have to handle large D20 or small D6 effectively? How many dice should it roll at a time?

- Form and Aesthetics: Sketch ideas! Consider the theme, overall shape (pyramid, castle, futuristic, abstract), size and desired level of detail.

- Internal logic: The heart of the tower! Understand how the baffle works – staggered plates force the dice to roll, randomizing its trajectory. The target has at least 3-4 baffles with different angles. Plan smooth entry ramps and exit paths. Make sure the maximum dice has enough gap.

- Tool selection: Utilize 3D modeling software.

- CAD software (Fusion 360, SolidWorks, Tinkercad): Best for functional design and parameter control. Ideal for making precisely tilted baffles.

- Engraving software (Blender, Zbrush): Very suitable for complex organic shapes, textures and character-based towers.

- Key Checkpoints: Watertight grid? Suitable wall thickness (usually dependent on material 2-5mm)? Exhaust hole? Minimal overhang? Split/assemble? Round corners? Access support?

-

Procure or create a model:

- Designed by yourself: The ultimate creative control requires CAD/sculpting skills and time.

- Commission Designer: Find a skilled CAD artist familiar with functional print or gaming aesthetics.

- Download and modify: Repositories like Thingiverse, Printables, or myminifactory offer thousands of designs. Remember permission! Use these as is or as inspiration to mix in CAD software.

-

Material Selection – Matching substances with styles and substances:

- PLA: Main force. Easy to print, wide range, stiff and biodegradable. Perfect for prototypes, displays and modest home use. It is prone to warp in heat and resists less impact than others.

- PETG: Durable upgrade. Excellent layer adhesion, impact resistance, temperature resistance, chemical resistance. "Full of vitality" Clearance is very popular. Feature tower that is perfect for watching regular games.

- ABS: Tough, impact-resistant, slightly flexible. Case that needs to be printed (ventilated required). Provides steam smoothing to the glass finish. Suitable for durable uses, but smoke needs caution.

- Asa: Like abdominal muscles, but with a little less anti-UV rays. Perfect for towers that may see the sun. Need a shell.

- Nylon (e.g. PA6, PA12): Extremely tough, wear-resistant and flexible. Great for high-end parts. Needs careful printing (dry, high temperature, housing). Professional performance.

- Resin (SLA/DLP/LCD): Unrivaled surface details and precision. Ideal for miniature decorative towers or highly sophisticated designs. Positively more fragile; there is a strong resin. Chemicals need to be cured and processed. The most undesirable Influence area.

- Metal (SLM/DML): The pinnacle of performance. think Stainless steel, aluminum alloy (such as Alsi10mg), titanium. Unrivaled durability, weight, heat resistance and accuracy. create Heirloom quality dice tower With excellent acoustics. Necessary for large capacity commercial production or super high-end custom works. Professional industrial equipment and expertise are required (more on our roles!).

- Selection factors: Durability, level of detail, weight, sound (metal vs. plastic), cost, printability.

-

Printing process and precautions:

- FDM/FFF (plastic wire):

- Support structure: Crucial for overhanging (bezel!). Use tree support to make it easier to remove where possible. Cleverly designed to minimize them.

- Layer height: 0.15mm -0.3mm. Lower = Smoother ramps/more details = longer prints.

- filling: 15-30% is usually enough. More fill = heavier/slower/stronger. Consider 100% of the critical joint areas.

- Wall (perimeter): 2-4 walls of walls.

- Surface finish: Grinding helps. Start/Fill is essential for smoothing the painting.

- Resin: Focus on direction to minimize support and suction. Clean and carefully cure. Careful post-processing.

- Metal (SLM/DML): Need advanced Industrial grade machinery and expertise. Precise laser melting required for metal powder:

- Specialized document preparation focuses on supporting strategies that support thermal stress/dimensional accuracy.

- Post-treatment: critical heat treatment (pressure relief), precise support removal, surface finish (sandblasting, tumbling, polishing, etc.).

- Significant advantages: Amazing strength to weight ratio, complex internal geometry can be manufactured for excellent durability – The ultimate solution for advanced or high volume dice towers requires absolute accuracy and longevity.

- FDM/FFF (plastic wire):

- Post-processing and finishing:

- Support removal: Carefully remove the support (scissors, pliers, precision knife). The sand blocks are smooth.

- Grinding: From coarse sand to smooth layer lines, especially on exit ramps.

- painting: Mainly! Use spray paint (light coat) or acrylate. Sealed with a sheer jacket (matte/gloss). Filling/priming is essential for the best results.

- assembly: If the modular design (epoxy, CA glue, plastic weld – matches the plastic type), the glued part is glued. Make sure to clean the bonded surface.

- Metal finish: Options range from industrial (evenly matte bead blasting, glossy CNC polishing) to art (Patinas, enamel). You can add hinges or grips.

Industrial Edge: Prototypes are in line with production

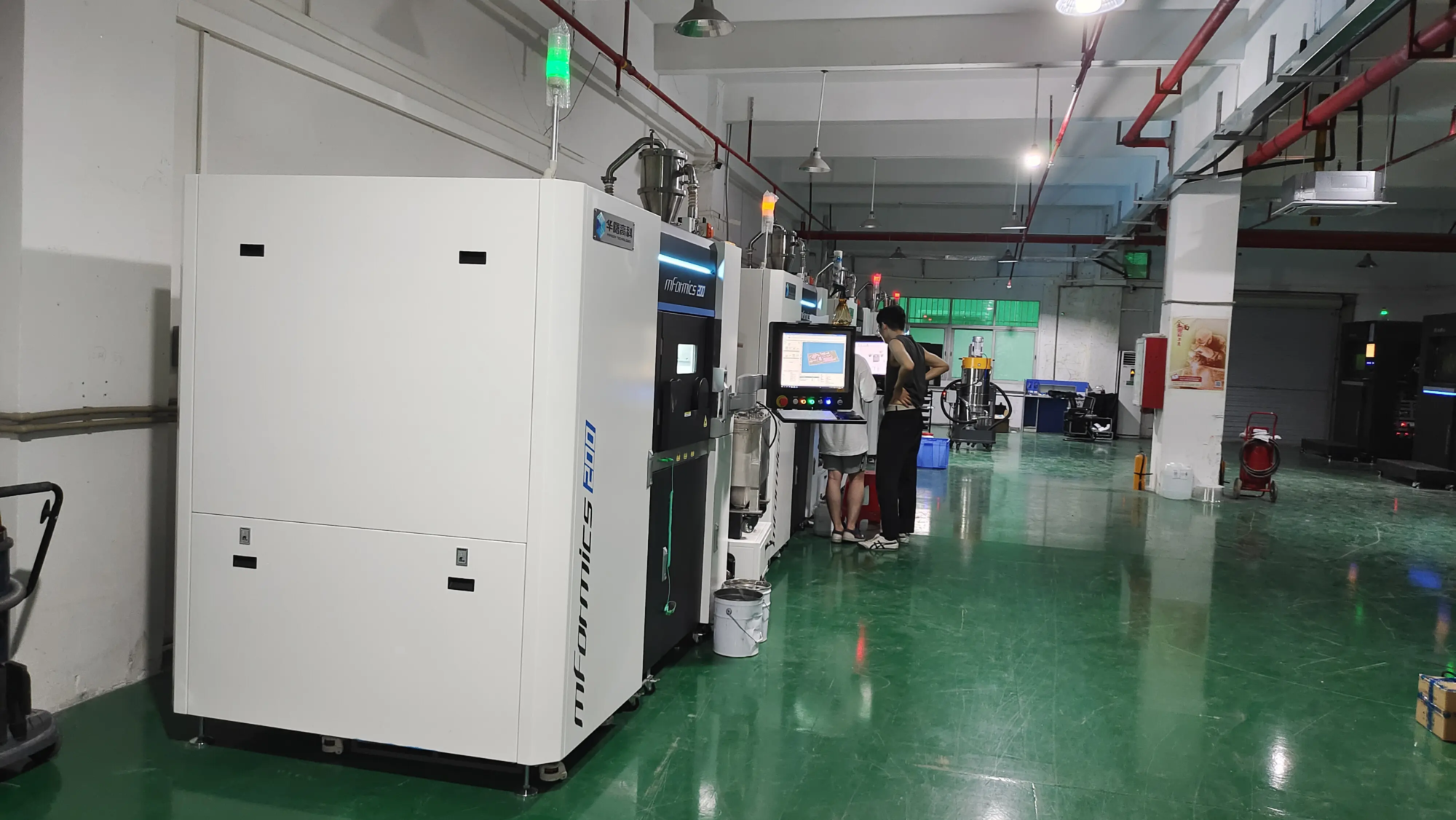

For game designers or entrepreneurs to build dice towers commercially, the leap from prototypes to high volume production requires more than FDM printers. That’s the expertise like us Great Become essential.

As Professional rapid prototype manufacturerwe specialize in research Blink the gap between design concepts and market-ready products.

- From FDM to Production Reality: Greglight adopts your initial FDM prototype and Complete design design. We analyze stress points, optimize the wall thickness of the metal, ensure smooth old-detached paths, and deal with tiny features that are prone to failure. Our Expert DFM (Manufacturing Design) Feedback Prevent expensive errors.

- Precision metal production: Need unrivaled durability to compete or promotion towers? Our Advanced SLM (Selective Laser Melting) 3D Printer Build a dice tower from high performance Metal alloys (stainless steel, aluminum alloy, titanium) With incredible accuracy and structural integrity. SLM creates parts intensive and robust for use in demand.

- Material flexibility and customization: Whether it is a specific exotic plastic such as reinforced nylon/peep or complex metal components, Greatlight offers a wide range of material options and Customized material solutions Meet unique performance requirements (e.g., specific weights, acoustics).

- Comprehensive post-processing: Beyond basic cleaning. We provide One-stop post-processing and completion service: Accurate support for disassembly, heat treatment, polishing (mirror explosion effect), shading/anodizing/painting, assembly and quality control inspection. Your dice tower is ready for shelves, tournament tables or collector displays – No dirty work required.

- Speed is crucial: We understand that the market is changing rapidly. Greglight is for Quick delivery No damage to quality. Our simplified process from digital models to parts completion ensures you meet deadlines.

- Solve complex problems: Struggling in baffle design, can a consistent random roll achieve, balancing aesthetics with metal structural integrity? Our team has Expertise in diagnosing and solving complex rapid prototyping challengesensure that the final dice tower performs perfectly.

Conclusion: From enthusiasts to business

3D printing enables everyone from amateur gamers to professional manufacturers to create exactly the dice tower they envisioned. The journey involves thoughtful design, the selection of smart materials, and mastering the printing and finishing process. Desktop FDM printer unlocks fantastic possibilities at home, access True production-grade metal 3D printing and professional finishing services unlock the ultimate layer of performance, durability and quality aesthetics.

Whether you are printing a unique tower for yourself, making designs for Kickstarter, or preparing for mass production, understanding and leveraging the capabilities of modern 3D printing, including the most advanced possibilities offered by partners like Greatlight – make sure your dice is loud, fair, fair, and incredible every time.

FAQ: Your Dice Tower Print Question Answer

-

Q: How to make my 3D printed dice tower fair?

- one: The key is the bezel! Multiple plates interleaved at different angles (ideally 3-5) within the tower, so the dice hits the edges unpredictable. Smooth entry and exit ramps are also crucial. Prototyping and testing different designs! Avoid completely parallel or mirroring bezels.

-

Q: What is the best material for durable 3D printing dice towers?

- one: For general use, PETG is excellent (tough, heat resistant, not as brittle as PLA). ABS/ASA is perfect for sturdy but difficult to print. Nylon offers excellent durability and flexibility. For ultimately, indestructible luxury goods, Metal alloys (SLM printed aluminum or stainless steel) It’s the peak.

-

Q: My dice keeps jamming in the tower. How can I solve it?

- one: Common reasons include: insufficient gaps in the dice size, too steep bevels of the baffle incline to wedge the dice, too much overhang can block the fall, or sticky residues in the tower (common with resin). Increase the internal dimensions slightly, adjust the angle of the bezel to make it lighter, ensure a clean internal edge and minimize lubrication if needed (gently spray silicone on the bezel).

-

Q: Should I design a tower on a part or a piece of tower?

- one: There are pros and cons. One piece by one minimizes seams/seas, but requires support of the inner baffle. Multi-sections make it easier to print complex overhangs, clean access, customize (swap top/bottom) and simplify painting. This is usually the preferred choice, especially for larger towers or complex designs.

-

Q: How important is the smoothness of the inner surface of the tower?

- one: Very important for dice flow! Rough surfaces, layers, spots or bad support removal points will grab the dice, resulting in jam. Carefully polish the inner baffle and ramp. Printing at lower altitudes improves internal traffic. Metal SLM parts essentially have a smoother interior surface than FDM plastic.

-

Q: Why do I choose professional metal 3D printing (such as SLM) as the dice tower?

- one: Metal printing offers unparalleled advantages for premium or commercial dice towers:

- Extreme durability: Almost unbreakable, endured drops and heavy use.

- Excellent feeling and weight: A large amount of weight conveys quality, excellent acoustics ("Click string"! ).

- High precision and details: Create complex internal geometric shapes with high dimensional accuracy for perfect rolling dynamics.

- Production scalability: Greglight can effectively produce consistent high-quality metal towers.

- Luxury aesthetics: Plastics cannot be unique, professional finishes.

- one: Metal printing offers unparalleled advantages for premium or commercial dice towers:

-

Q: What are the post-treatment options for plastic and metal towers?

- Answer: Plastic: Grind, primer, painting, clear coating, light polish. Metal (in Greatlight): Sand/soda blasting (various finishes), CNC polishing (with mirror gloss), vibration rolling, chemical polishing/passivation, electroplating, anodizing (aluminum), powder coating, paint, heat treatment.

- Q: I have a complex design. How do I get started with professionalism?

- one: GRESTLIGHT specialized research Solve complex rapid prototyping and production challenges. Just share your 3D model with us! We provide expert designs for manufacturing (DFM) feedback, material recommendations for your needs (from engineering plastics to exotic metals), and handle Everything from precision printing to final finishprovide prototype or end-use parts ready for production. Customize the tower at the best value. Get your custom quote now!