Shaping the Future: Navigating the Exciting Career Landscape of 3D Printing Engineering

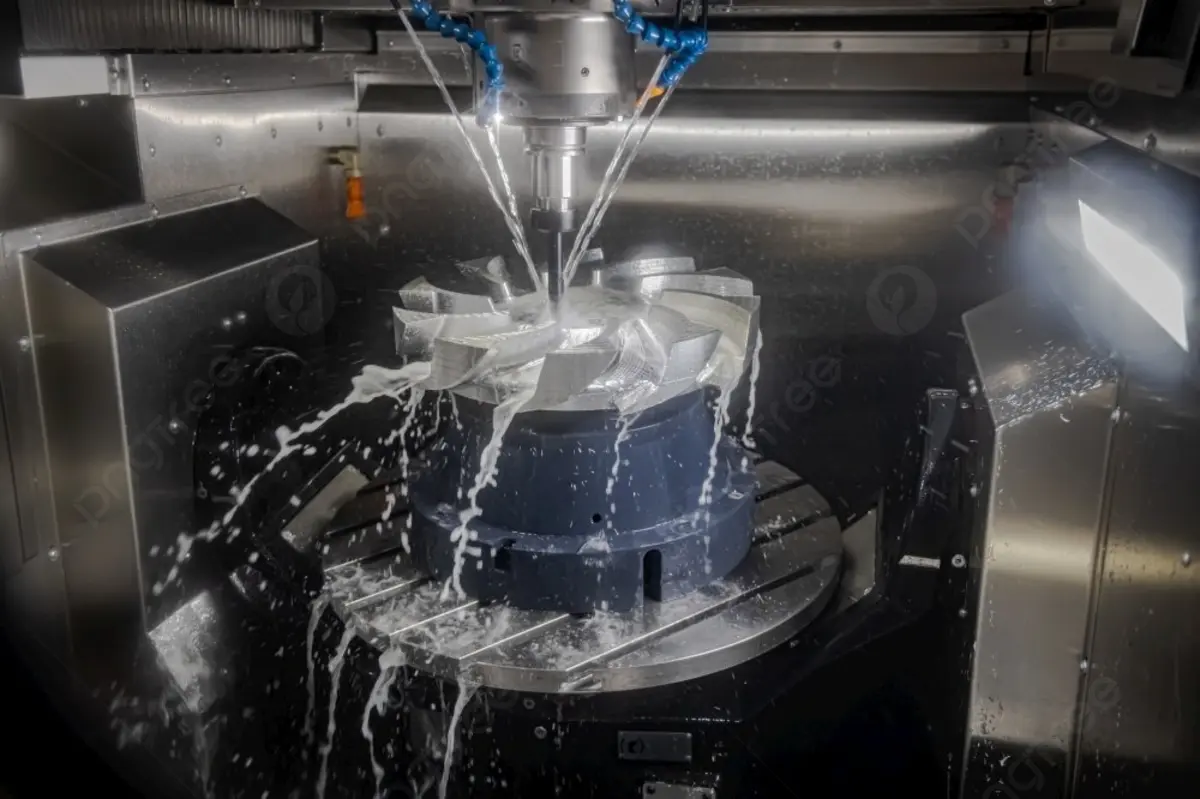

The resonant hum of the printer layeres the molecules of the material molecule by molecule, transforming the digital blueprint into tangible functional objects – this is the evocative reality (AM) of additive manufacturing (AM), commonly known as 3D printing. Apart from the microcosm of amateurs making, it is a profound industrial revolution that fundamentally changes how we design, prototype and manufacture in aerospace, healthcare, automotive and consumer goods. The forefront of this transformation is the bridge design of 3D printing engineer-curator with physical reality. If you are fascinated by technology, innovation and problem-solving problems that solve complex problems, a career in 3D printing engineering can provide dynamic and beneficial paths.

More than just operating a printer: The essence of 3D printing engineering

Eliminate the Myth: 3D Printing Engineers Are More Better than the machine operator. They are multidisciplinary problem solvers, combining in-depth understanding of physics, materials science, mechanical design, computer-aided design/engineering (CAD/CAE) and specialized manufacturing principles. Their mission is:

- Unlock design freedom: Leverage AM’s ability to create geometry through traditional methods (internal channels, lattice structures, topologically optimized components).

- Optimization process: Determine precise parameters (laser power, scanning speed, layer thickness, temperature, support strategy) for a specific material and geometry to achieve the desired characteristics and minimal defects.

- Main Materials: Understand the complex interactions between raw materials (polymers, metals, ceramics, composites) and the printing process, predict and influence microstructure and final part performance.

- Integration post-processing: Consider the necessary downstream finishes (heat treatment, surface finishing, hips, machining), design parts and processes for the final function.

- Drive innovation: Continuously explore new applications, improve existing technologies, reduce costs and increase sustainability.

Various career paths in 3D printing engineering

The field is vast and offers professional avenues based on your passion and skills:

Process Engineer: The core of production. Focus on developing, optimizing and scaling specific printing processes (e.g., SLM, SLS, FDM, SLA, Binder Jetting). Expertise includes parameter adjustment, machine calibration, material qualification, defect analysis and ensuring consistent high-quality parts output. Work closely on store floors often.

- Skill: In-depth process knowledge, statistical analysis (SPC), DOE, metallurgy/polymer science, problem solving, careful attention to detail, machine operation expertise.

Application Engineer: The bridge between customer needs and technical feasibility. Work directly with customers to understand their challenges, design parts for AM, select the best materials and processes, guide design optimization (DFAM), prototype and validation solutions. Provide key technical sales support.

- Skill: Excellent communication, strong DFAM principles, technical sales acumen, CAD capabilities, a broad understanding of AM technology and materials, project management.

R&D (R&D) Engineer: Push the boundaries. Engaged in developing new materials, novel printing technologies, improving existing processes (faster, cheaper, higher performance), exploring unique applications (bioprinting, electronics), and addressing basic materials science challenges related to AM.

- Skill: Strong analytical and research background, deep scientific understanding (metallurgy, polymer physics, thermal fluid dynamics), innovative thinking, experimental design, data analysis, publishing skills.

Design by Additive Manufacturing (DFAM) Engineer: Specializes in taking advantage of the unique features of AM from the first sketch. Optimize printability and performance CAD models with lattice structure, topology optimization, part merging and generation design tools. Ensure the manufacturability of uncompromising functions.

- Skill: Advanced CAD/CAE (especially AM simulation tools), a deep understanding of AM processes and constraints, mechanical design principles, creativity, and topological optimization.

Materials Engineer (specially for AM): Focus entirely on the material side. Develop or limit new metal alloys, polymers, ceramics or synthetic materials specially formulated for additives. Analyze microstructures – specially made relationships and post-printing, develop material models for simulation, and build processing structures – training envelopes.

- Skill: Materials Science/Engineering Degree, Feature Technology Expertise (Microscopy, Spectroscopy, Mechanical Testing), Understanding of Phase Transformation, Powder Metallurgy (for Metals), Polymer Chemistry.

Simulation Engineer (AM Focus): Use advanced computing tools to simulate the complex physics of the printing process (thermal stress, melt pool dynamics, distortion) and predict the final partial properties forward print. For minimizing trial and error, it is crucial to predict failures and actually optimize the build parameters.

- Skill: Computational mechanics, finite element analysis (FEA), CFD, multiphysical simulation, programming, a deep understanding of AM thermal/mechanical phenomena.

Metering and Quality Engineer (AM context): Ensure printed parts meet strict quality standards. Professional inspection protocols for complex AM geometry were developed using CT scanning, 3D scanning and advanced microscopy. Implement statistical process control (SPC) and data-driven quality assurance systems, unique challenges specific to AM.

- Skill: Metering expertise (non-destructive testing, GD&T), data analysis, SPC, quality systems (ISO), understanding of AM defect patterns, CT/SEM/XRD explanations.

- AM Production Manager/Operation Leader: Oversee the entire AM production facility to ensure smooth workflows, optimize resource allocation (machinery, materials, personnel), manage budgets, implement safety protocols, and improve efficiency and productivity improvements.

- Skill: Strong leadership, project management, operations management, budgeting, communication, a deep understanding of AM production workflows and challenges.

Where did you start? Educational Pathways

- undergrad: A bachelor’s degree in mechanical engineering, materials science and engineering, manufacturing engineering, aeronautical engineering or related fields is typical of the foundation. Look for programs that offer professional AM courses, certificates or labs.

- postgraduate: Master or PhD programs in advanced manufacturing, materials engineering or specialized AM programs provide deeper specialization and research opportunities, especially value for R&D or technical roles.

- Certification: Industry-recognized certification in specific software (CAD, simulation), process (ASTM/ISO AM standard) or DFAM principles greatly improves credibility and employment.

- Practical experience: Crucial! Seek internships, cooperatives, research projects, and even personal projects for designing, printing and testing parts. Understanding the actual reality is priceless. Contribute to open source projects or online AM communities, build networking and practical knowledge.

Conclusion: Exercise the path in the changing industry

3D printing engineering is more than just a job; it is an opportunity to become a future architect. As technology develops at an astonishing rate, it requires technical acumen, innovative thinking and a passion for continuous learning. From the perfect printing parameters of the carefully crafted key jet engine turbine blades to the design of lightweight biosimulated implants, the effects are tangible and profound.

Career paths are diverse, from deep technical specialization to customer-oriented roles and strategic leadership. The company likes it Great,exist Metal additive manufacturingreflects the advanced industrial applications that truly shine by 3D printing engineers. Take advantage of the most advanced SLM (Selective Laser Melting) Printer And have deep expertise Process optimization, complex material behaviorand Key post-processing techniquesGremight solves the most demanding rapid prototyping and production challenges. Their capabilities One-stop solution – covering precise printing, custom material handling and expert finishing services – Emphasizes the essential comprehensive skill set in modern AM engineering and demonstrates the work of complex ecosystem professionals operating in it.

Whether you are attracted by the complexity of materials science, the elegance of computational simulation, the creativity of design, or the challenges of high-risk production, 3D printing engineering can be dynamic, influential and meaningful careers at the forefront of manufacturing. The factories of the future are built layer by layer, and skilled engineers are essential builders.

FAQ: Your 3D Printing Engineering Career Questions Answered

Question 1: Does it require a master’s degree to get a good job in 3D printing engineering?

Answer: Not sure. Relevant bachelor’s degree combines strong hands-on experience, proven skills (e.g. CAD, specific AM process experience), relevant certifications and enthusiasm to find excellent entry-level positions (e.g. technicians, junior process engineers, application support). However, a master’s or PhD degree becomes very beneficial for research-intensive roles (R&D, material development, advanced simulation), dedicated niche or position designed to rapidly improve leadership.

Q2: What is the typical salary range for 3D printing engineers?

A: Salary varies greatly depending on location, experience, industry, specialization and company size. The entry-level role may start in the $60,000-$80,000 range. Experienced process, application or design engineer can earn $80,000-$120,000+. In research and development or management in areas such as aerospace or MEDTECH, highly professional roles may exceed $120,000+. Technology/manufacturing specific benefits and bonuses also apply.

Q3: Which industries employ the most 3D printing engineers?

A: This field spans multiple departments:

- Aerospace and Defense: Lightweight, complex internal structure, old parts.

- Medical and Dental: Custom implants, surgical guides, tools, bioprinting research.

- Cars and Motorsports: Prototypes, lightweight components, custom tools.

- Industrial Equipment: Special fixtures/fixes, spare parts on demand.

- Dedicated AM Service Bureau: (Just Greatlight) Prototyping and production services in different industries.

- Consumer Products: Custom, prototype, complex design.

- vitality: Turbine assembly, heat exchanger.

Question 4: What is the biggest challenge in the 3D printing engineering career?

A: The main challenges include:

- Rapid technological change: There is constant need to learn new machines, materials and software.

- Process complexity: Master many interdependent parameters that affect part quality.

- Substance limitations and variability: Understand and mitigate unique AM material behaviors and inconsistencies.

- Postprocessing complexity: Integrate and optimize cleaning, heat treatment, machining and surface finishing.

- Standards and Qualifications: Working in an evolving regulatory landscape, especially for safety-critical parts.

- Adopt business: Compared with traditional methods, it is sometimes necessary to justify the return on investment of AM.

Question 5: How important is design to additive manufacturing (DFAM)?

Answer: DFAM is Absolutely critical. The unique advantages of AM can only be fully utilized only when designed specifically for the process from the beginning. engineer must Understand DFAM principles for weight loss, part merger, performance growth and manufacturability. This is not just an add-on; it is crucial to implement successfully.

Question 6: Which skills are becoming increasingly important in this field?

Answer: Beyond the core engineering skills:

- Data Analysis and Machine Learning (ML): Used for process monitoring, anomaly detection and predict quality.

- Advanced simulation: Multiphysical modeling of the entire printing process.

- Automation integration: Robotic technology for powder processing, part removal, and post-treatment.

- Software skills: Proficient in AM-specific software suites (simulation, build preparation, PLM).

- Digital threads: Learn how to integrate into digital manufacturing workflows (IoT, MES, ERP).

- Sustainability awareness: Optimize resource usage, energy efficiency and life cycle.

Question 7: How do companies like Greatlight leverage the skills of these engineers?

A: Advanced manufacturers like Greatlight need this diverse talent pool to provide high-value services:

- Process Engineer: To optimize its SLM printing parameters for use in different metals and complex parts.

- Application Engineer: Work with customers on DFAM and convert challenging requirements into printable functional solutions.

- Materials Expert: Handle complex alloys and ensure material characteristics meet specifications.

- Post-processing experts: Proficient in managing critical completion steps required for aviation or medical applications (precise machining, polishing, hip joints).

- Measuring Engineer: Use advanced CT scans to verify dimensional accuracy and internal integrity of precise prototypes and production parts.

Taking a career in 3D printing engineering means entering a field that actively reshapes the world how to build things. It is demanding, constantly changing for those who have the curiosity and dedication to master it.