As professionals in the field of rapid prototyping, we understand the importance of achieving high-quality 3D prints. But despite the best efforts of manufacturers and technicians, there are and do happen 3D printing failures. In this article, we will explore common causes of 3D printing failures, the consequences, and most importantly, what measures can be taken to prevent or mitigate them.

3D printing is a complex process involving the interaction of multiple factors, including the 3D printer itself, the printing material, the design of the printing object, and the printing environment. Any difference or failure of these factors can lead to 3D printing failure. Some common causes of 3D printing failures include printing at wrong temperatures, incorrect beds, insufficient adhesion, and the use of low-quality printing materials.

One of the most frustrating types of 3D printing failures is the “print lift.” This happens when the printed object starts to lift the printing bed during printing, causing the object to be disengaged and render it unusable. This may be caused by insufficient adhesion between the object and the printing bed or due to temperature fluctuations.

Another common problem is “strung up” or “leak out”, where excess molten material is deposited between the layers, resulting in a messy print. This may be caused by incorrect retraction settings, too high printing temperatures or clogged nozzles.

In addition to these technical issues, human errors can also play an important role in 3D printing failures. For example, incorrect calibration of 3D printers, incorrect slice settings, or failure to follow the appropriate printing process can lead to secondary printing.

So, how to prevent or mitigate 3D printing failures? First, it is necessary to ensure that the 3D printer is properly calibrated and maintained. This includes regular cleaning and lubrication of moving parts, as well as updating the printer’s firmware and software. Second, the printing materials should be of high quality and suitable for specific printing applications. Third, considering factors such as wall thickness, overhang and support, it should be optimized for 3D-printed object design.

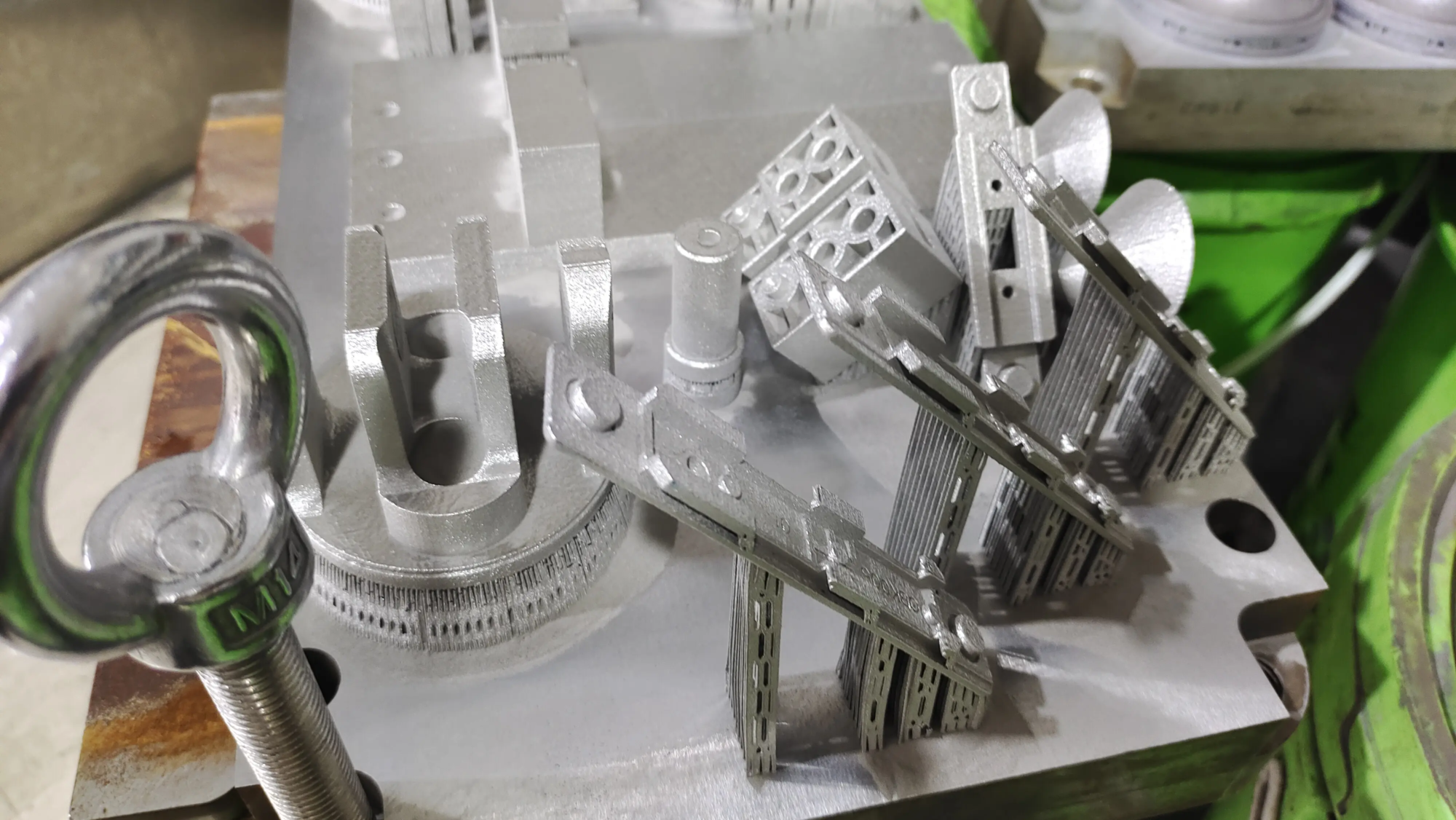

At Greatlight, we understand the importance of producing high-quality 3D prints. Our team of experts has many years of experience in rapid prototyping and 3D printing, and we use only state-of-the-art SLM 3D printers and production technologies to produce metal parts with precision and accuracy. We also offer one-stop post-processing and completion services to ensure our customers receive their parts under the exact conditions required.

In short, 3D printing failures can be frustrating and expensive, but by understanding common causes and taking steps to prevent or mitigate them, manufacturers and technicians can significantly improve the quality and reliability of their prints. By choosing a well-known and experienced rapid prototyping manufacturer, such as Greatlime, customers can ensure that their 3D printed parts meet the highest standards of quality and accuracy.

FAQ:

Q: What are the most common reasons for 3D printing failure?

A: The most common causes of 3D printing failures include printing at wrong temperatures, incorrect beds, insufficient adhesion and the use of low-quality printing materials.

Q: How to prevent “print lift”?

A: To prevent “print lifts”, make sure to level the printed bed correctly and securely secure the object to the bed using adhesive or other means.

Q: What is “string” or “exudation” in 3D printing?

A: “string up” or “leakage” refers to the deposition of excessive molten material between layers, resulting in messy and imperfect prints. This may be caused by incorrect retraction settings, too high printing temperatures or clogged nozzles.

Q: How to ensure high quality of my 3D printed parts?

A: To ensure that your 3D printed parts are of high quality, choose a well-known and experienced rapid prototyping manufacturer (such as Greatlight) and ensure that the printing materials and designs are suitable for a specific application.

Q: What services does Greatlight provide?

A: Greatlight provides fast prototyping services including 3D printing, post-processing and completion services, as well as custom metal parts to meet specific customer needs.

ISO 9001 Factory