Unlocking complex sports: Your guide to 3D printed gear balls

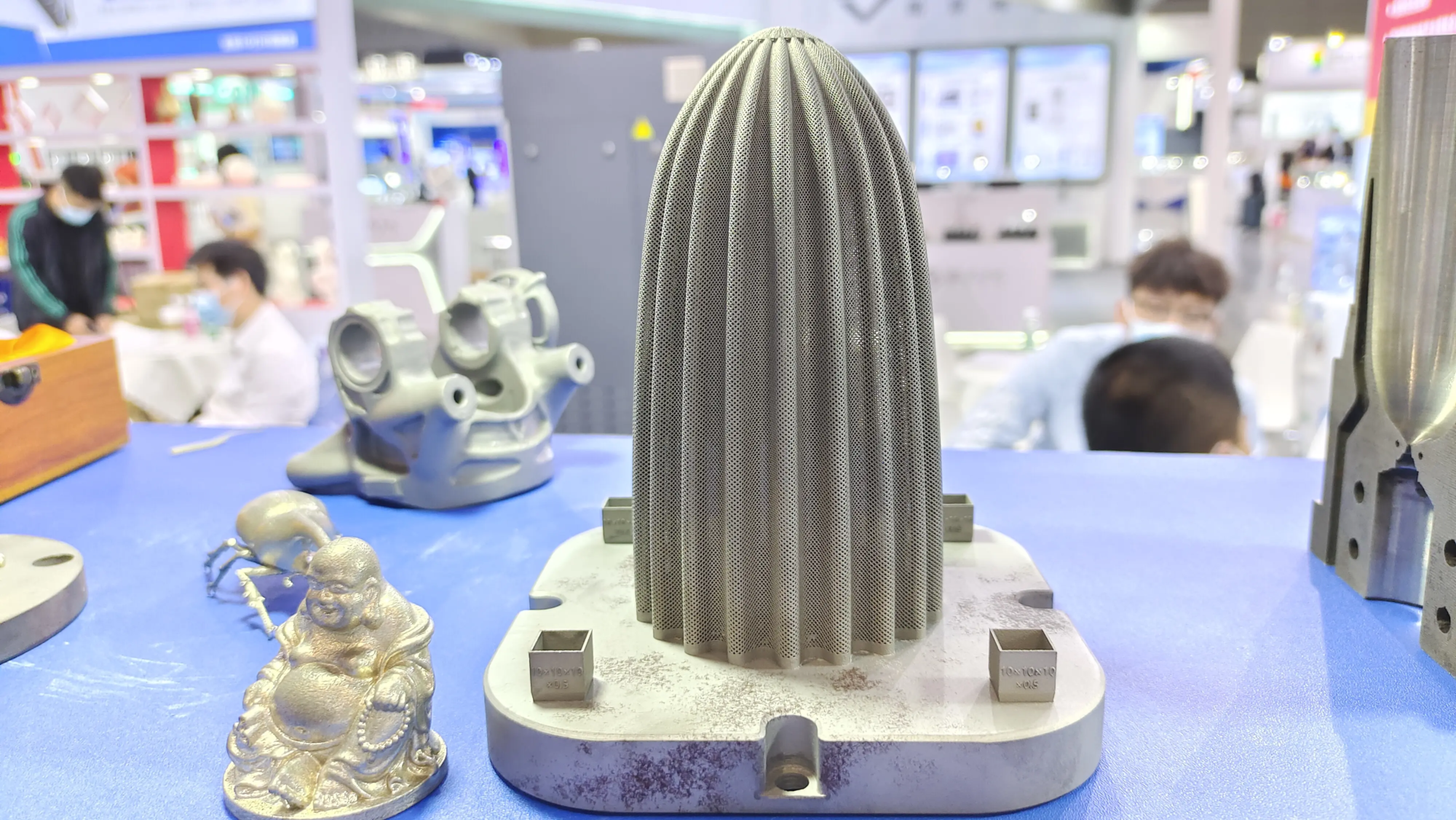

The fascinating complexity of gear balls – a multi-axis puzzle ball composed of intricate interlocking gears – has attracted designers, engineers and puzzle lovers over the years. Traditionally, creating these fascinating objects with moving internal components is a major challenge, often requiring expensive molds, professional tools and assembly gymnastics. Enter 3D printinga revolutionary technology that changed the way we conceived and created objects such as gearballs. This blog post introduces the world of 3D printed gear balls, explores challenges, solutions that additive manufacturing offers and why expertise matters.

The charm and pain of the gear ball

Functional gear balls are a miracle of mechanical design. Multiple nested balls, each of which is divided into gear teeth, must be perfectly meshed on multiple axes. Achieving smooth, reliable movement, seamless contact of gears from any direction is not a small feat. The main challenges of traditional manufacturing include:

- Complex internal geometry: It is nearly impossible to perform intricate pathways and interlocking teeth inside solid spheres.

- Conference Nightmare: It is very difficult to process individual gear segments separately and assemble them internally, often requiring complex fixtures and compromising tolerances.

- Accurate tolerance requirements: Micron-scale accuracy in gear teeth and gaps is crucial for smooth rotation without bonding or overplaying.

- Material constraints: Finding materials that are strong enough for thin gear segments, but suitable for precise machining will add another layer of difficulty.

Why 3D printing is a game-changer

3D printing, especially like Metal powder bed fusion (e.g., SLM-selective laser melting)face these challenges head-on:

- Free Complexity: Additive manufacturing builds objects layer by layer directly from the digital model, making these impossible internal geometries abruptly possible. You design it; the printer builds it, invalidate it, all with one piece or a minimal, intelligently designed subcomponent.

- Integrated assembly: Strategic 3D printing can combine voids, channels and mechanisms that allow printing complex components such as nested gear balls. As a pre-assembled unit Or just a simple final assembly step is required. Functional hinges and moving parts are built-in.

- Accuracy and repeatability: Advanced industrial 3D printers, especially SLM systems, have excellent dimensional accuracy and finishing capabilities that solve good details and tight tolerances that are critical to gear meshing.

- Material versatility: Metal 3D printing provides access to high-strength and durable materials (e.g. Stainless steel (316L, 17-4PH), aluminum alloy (ALSI10MG, ALSI7MG), titanium (TI6AL4V), even specialized tool steel or nickel alloyperfect for functional, wear-resistant gears.

Key considerations for 3D printing of functional gear balls

Successfully printing a gear ball requires not only a hit, but also a "Print." It requires expertise:

-

AM design optimization: CAD Model must Considering 3D printing limitations. This includes:

- Support policies: Determine the support required for the overhang of the gear teeth or internal structure and how to remove it effectively.

- Wall thickness and strength: Ensure that the gear teeth and connection structure are thick enough to successfully perform the material and printing process without warping or layering.

- Gear profile and clearance: Design an accurate (or similar) gear profile with calculated rebounds to smooth the grid, which is potentially secondary printing variance.

- Internal clearance: Define enough gaps between moving parts to prevent post-bonding printing and post-processing.

-

Material selection: Select according to the application:

- Visual/Desktop Toys: Stainless steel, aluminum provides aesthetics, decent strength and corrosion resistance.

- Functional prototype/demonstrator: Engineering grade stainless steel (17-4PH), aluminum, may be higher loads of titanium.

- High pressure applications: Although complex fatigue loads are a major challenge, consider using tool steel or nickel alloys.

-

Key post-processing: Metal 3D printed parts are done directly from the printer:

- Support removal: Careful and precise removal is essential for preserving gear teeth.

- Surface finish: Rolling, sand blue, vibrating finishing surface, partial removal "Stair steps". For ultra-smooth mesh seams, precision polishing and even specialized electrochemical polishing can be used internally.

- Heat treatment: Materials such as 17-4ph require heat treatment to achieve their full strength and hardness characteristics, which is essential for durable gears.

- Secondary processing: Sometimes, critical bearing surfaces or component interfaces may require CNC machining to achieve final accuracy.

- Verification and testing: Strict inspections (CT scans may be invaluable for internal scanning), functional testing is essential to ensure perfect motion.

(Spotlight: Greglime – Your partner in Precision Metal AM)

Successfully navigating the complexity of designing, printing and completing functional metal gear balls requires partners with deep expertise and advanced features. This is Great Good at it.

As a professional rapid prototyping manufacturer at the forefront of metal additive technology, Greatlime has:

- Advanced SLM 3D Printer: Equipped with the latest powder bed fusion technology, it can be used for the high resolution printing required for complex gear teeth and fine functions.

- Master metal materials: From standard stainless steel and aluminum to titanium and more exotic alloys, their unique printing characteristics and post-processing requirements can be understood to handle a wide range of materials.

- End-to-end solution: Gregtime is more than just printing. They provide real One-stop post-processing service: Experts support removal, complex finishes (including complex internal polishing techniques), heat treatment coordination and precise CNC machining integration needs.

- Quickly customize and compete for pricing: Focus on solving rapid metal prototype problems quickly and effectively. Most materials can be processed under pressing deadlines without sacrificing quality, making them one of China’s leading providers of rapid prototyping for demanding applications.

Whether your gear ball is an amazing design display cabinet, functional engineering presenter, or components in a larger mechanism, leverage professional AM expertise such as Greatlight’s ensures the highest quality, functionality and timely delivery.

Beyond the puzzle: Applications

While the iconic is the puzzle, the principle of 3D printing gear balls has found applications in more serious areas:

- Project protesters: Explain complex multi-axis gear concepts.

- Educational tools: Professor of mechanics, gears and advanced manufacturing.

- Replace components: Custom replacement internal gear mechanism damaged (if within size/load feasibility).

- Professional Instruments: Potential applications in gyroscopes or complex flow control valves involve multi-directional motion transfer.

- Art and Sculpture: Push the boundaries of the art of dynamics.

in conclusion

Compared to traditional methods, 3D printing has unlocked the ability to create functional gear balls with unprecedented ease and precision. Transforming from a fascinating concept in CAD to a smoothly rotating sphere in your hand requires understanding of AM design rules, choosing the right materials, applying meticulous post-processing, and identifying machine limitations. Working with experienced metal 3D printing providers, equipped with advanced SLM technology and comprehensive finishing services, greatly enhancing the success of these complex projects. It transforms the impossible of manufacturing into a tangible functional reality. Gearball demonstrates how additive manufacturing has revolutionized the creation of geometric complex, multi-part mechanisms.

FAQ: 3D printed gear balls

1. Can I download the gear model and print 3D by myself?

- you able Download and try to print the model, but The results vary greatly. Designs on free platforms often lack specific optimizations. Printing functional metal gear balls requires industrial SLM printers, complex support strategies, and rigorous post-processing that goes beyond hobby capabilities. The resin/FDM print may be useful as a visual model, but lacks the strength and accuracy of the smooth, reliable metal network fusion expected in a true gear ball.

2. What are the biggest challenges in 3D printing of functional gear balls?

- accomplish Reliable and smoothly across all interlocking gears across multiple axes back Printing and post-processing. This pair:

- Design perfect rebound and tooth profile optimized for potential small deviations.

- Detailed support removal without damaging fragile gear teeth.

- Achieve adequate smoothness on the internal contact surface (it is difficult to complete within the sphere!).

- Relieve thermal stress/distortion during metal printing, which may distort critical geometry.

3. The durability of 3D printed metal gear balls?

- Durability depends to a large extent on Material and Post-processing. Properly printed and heat treated stainless steel (e.g. 17-4ph) or titanium (Ti6al4v) gear balls designed with sufficient tooth strength can be very robust for protesters or lamp load applications. They usually no The purpose is to act as an industrial power transmission component under heavy, continuous loading – over time, wear will be a factor without lubrication. Setting realistic expectations based on material selection is key.

4. How long does 3D printing take and the gear ball is completed?

- Production time involves multiple stages:

- Design Optimization/Comments: 1-3 days (existing models are required if needed).

- print: Depends on size and printer. Balls with a diameter of 100mm may require more than 10-30+ hours of industrial SLM machines.

- Post-processing (key): Supports removal, finishing, heat treatment – Depending on the complexity, the selected finish (e.g., internal polishing) and heat treatment cycle, this can easily increase by more than 3-7 days. Real expectations 1-2 weeks total turnover For high-quality metal parts for professional service providers like Greatlight.

5. Why choose a professional service like Greatlime instead of trying it yourself or using a cheaper one?

- Expertise: Greatlight handles complex AM challenges every day – optimizes direction/support, selects parameters for gear accuracy, and selects the correct material/post-processing strategy.

- Advanced equipment: Industrial SLM machines offer excellent resolution, repeatability and material options that are critical to functional gears.

- Completed: Access specialized technology that is not available for support disassembly and interior finishes that are not available for DIY or basic services.

- Reliability and quality: A proven process ensures that the final product can actually go smoothly. Cheap providers often cut corners in support strategies or finishing, resulting in damage to equipment or parts.

- Material Certification: Professional services ensure material traceability and provide documentation when needed.

If you need functional, high-quality, truly impressive 3D printed metal gear balls (whether in engineering, design or precise presentation) working with leaders of metal rapid prototypes such as Greatlight is the most reliable way to succeed. Contact us today to discuss how we can transform your complex gear mechanism vision into reality.