Unlock Custom Magic: Your Final Guide to 3D Printed Gibbets

Desire for a pair of crocodiles that really reflect your personality? Jibbitz – those iconic charms that pop out of the crocodile shoe hole – is the ideal canvas for self-expression. But why adapt to mass-produced designs when you can create unique custom charms? Entering the world of 3D printed Jibbitz, imagination fits in precise manufacturing. This guide takes a deep dive into everything you need to know about design, production, and having custom Gibitz, leveraging the cutting-edge power of modern 3D printing technology.

Why 3D Print Your Gibbets?

- Final Personalization: Design with charm of your pet, favorite logo, internal joke or original artwork. Stand out of the crowd with a unique talent.

- Unrivaled details and complexity: With traditional injection molding, complex geometric shapes, textures and miniature details cannot be achieved.

- Small batches and prototypes: Perfect for testing designs, creating limited edition runs or having personalized gifts without a large number of minimum orders.

- Material versatility: Explore a wide range of aesthetics and characteristics – from lightweight plastics to premium metals.

- Create on demand: When you need it, you can produce exactly what you need, reducing waste and inventory costs (especially for businesses).

Jibbitz Journey from 3D Printing: From Concept to Croc

1. Design: bring your vision to life

- Concept sketch: Start with a clear idea. Consider size (the diameter of the standard Gibitz is about 15mm and has different heights), complexity and it "Back" To fix the shoes.

- CAD Modeling: Translate your sketches using 3D modeling software (Tinkercad for beginners, Fusion 360 or blender for advanced users). Pay close attention:

- Anti-slip cleats: The backbone of the Jibi tribe! This small cylindrical pin (approximately 5mm in length and approximately 5mm in diameter) must be strong and precisely sized to securely insert it into the alligator hole without loosening or damaging the shoe. Design it as an integral part.

- Wall thickness: During printing and use, ensure a uniform thickness (usually 1mm+ plastic, adjusting the metal) for structural integrity.

- Dangling and support: Designed to minimize overhangs that require support material, which may leave markings. Smooth curves are usually better than clear undercuts.

- Document preparation: Export the design as an STL or 3MF file. This universal format is ready for slicing software to be ready for printing.

2. Material Selection: Balancing aesthetics, durability and cost

- Plastics (FDM/SLA):

- PLA: Biodegradable, user-friendly, wide range, affordable. Best for low-coat decorative charm. Maybe crunchy.

- ABS: Stronger and more temperature resistant than PLA. Bed and shells that require heating. Good durability. Smells during printing.

- Resin (SLA): UV cured resins offer excellent smoothness, detail and diversity (standard, tough, flexible, castable). Great for highly detailed charm. The cured resin is rigid, but can be fragile unless a special mixture is used (e.g., durable/long life resin). Need to cure.

- Metal (SLM/SLS- Gremight Advantage):

- Nylon insert metal (e.g., aluminum): The polymer is mixed with metal powders such as aluminum to provide a metal appearance, good detail and impact resistance. Usually used for functional prototypes.

- Solid Metals (SLM): This is Gre Big Doctor’s expertise shines. use Selective laser melting (SLM)They can produce Jibbitz from powerful materials Stainless steel (316L),,,,, titaniumor Aluminum alloy.

- benefit: Unrivaled strength, durability, advanced feel, heavy presence, biocompatibility (titanium). Ideal for designs that are easy to break or require extreme life and high-end finishes.

- Notes: More costly, longer production time, much heavier than plastic/resin.

3. Printing the Perfect Charm: Technology is Important

Choose the technology that aligns with your material, detail and durability needs.

- Fusion Deposition Modeling (FDM): Melt the plastic wire layer by layer. Advantages: Accessible, inexpensive printer, powerful parts. Disadvantages: visible layer lines, low detail resolution, requiring post-processing to smooth. Best for simple PLA/ABS JIBBITZ prototypes or decorations, with high details not important.

- Stereo-lithography (SLA): UV light is used to cure the liquid resin layer by layer. Advantages: Surface Surface Excellent surface, high detail and accuracy. Disadvantages: After careful resin treatment and curing, the parts may become brittle without using special resin. Best for highly detailed plastic/resin charm.

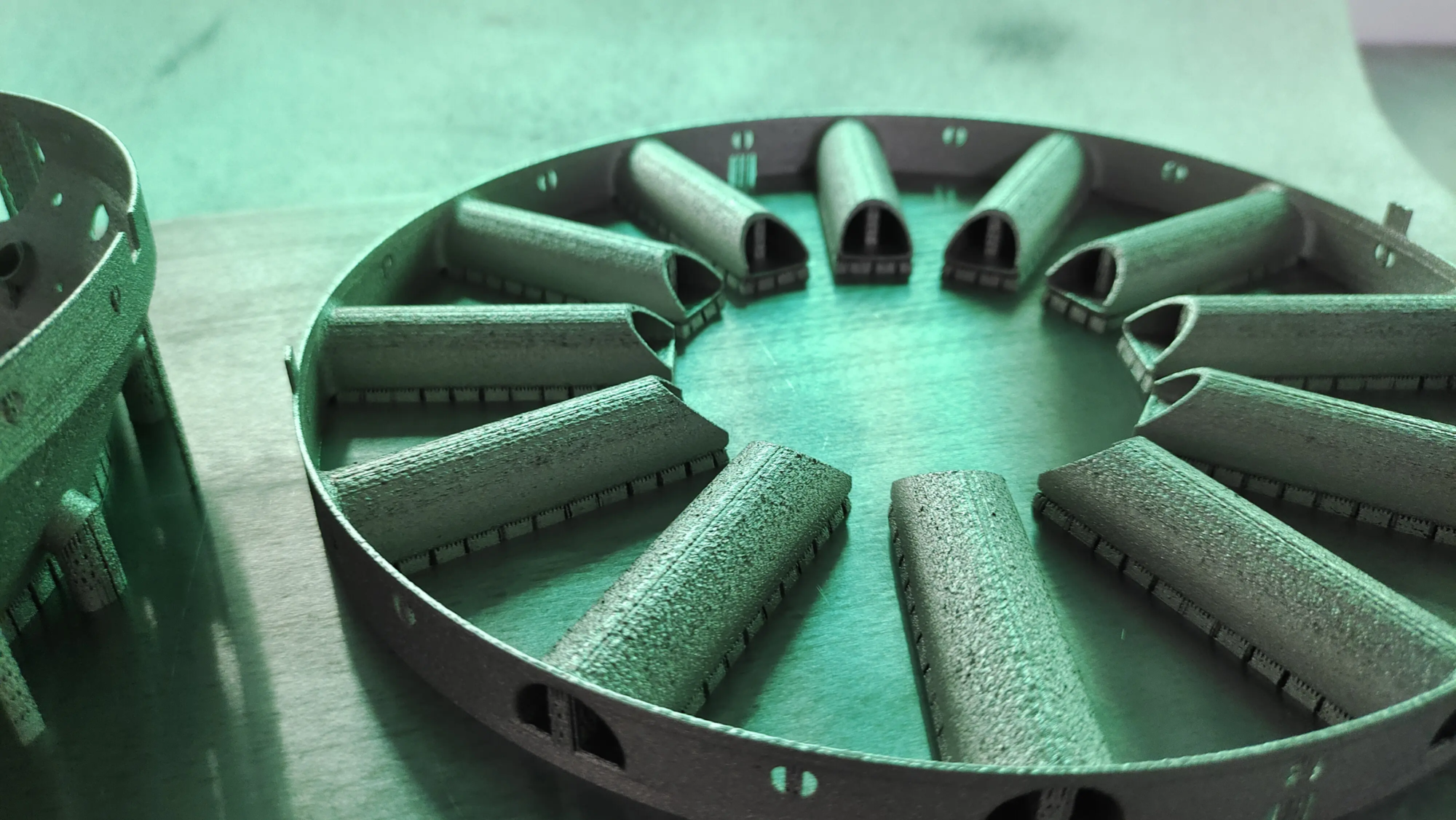

- Selective laser melting (SLM): (Industrial Specialty) Completely fuse fine metal powder particles using high-power lasers. Generate completely dense metal parts.

- Why Greatlight does a great job here: They leverage advanced SLM equipment and proprietary process knowledge to overcome the challenges faced by printing small complex features such as Jibbitz Cleat Pin. Their expertise ensures that the small needles catch firmly without breaking, and that the entire charm maintains structural integrity despite their small size. This requires precise laser control, optimized scanning strategies and a deep metallurgical understanding – something that amateur printers cannot achieve.

4. Post-processing: Polish your masterpiece

Original 3D printed parts often require improvement, especially for consumer-facing items.

- plastic:

- Support removal: Carefully shear and polish the structure.

- Grinding and polishing: The surface of the sand is gradually smooth. Can wet sand metal for a high quality finish.

- Painting/Sealing: Starting and painting enhances aesthetics. The sheer jacket is sealed and protected. Possible for electroplating of resin printed materials (e.g., gold, chromium).

- Metal (SLM):

- Powder removal and stress relief: Partially recycled, clean excess powder and heat-treated to relieve internal stress.

- Supports deletion and completion: Highly accurate cutting/grinding to remove metal support. A skilled technician is required to avoid damage to parts. Various finishes possible: matte or polished smooth.

- Greglight one-stop service: Crucially, like Great handle all Necessary post-treatment – Experts support disassembly, pressure-reducing heat treatment, precise machining with precise precision and required surface finishes – ensures that the final metal Gibbie Bibiz is not only printed out, but is professionally finished and can be worn.

Why collaborate with Pro for your Jibbitz project?

Creating functional, durable, high-quality 3D printing Jibbitz, especially in metals, is an engineering challenge beyond hobby capabilities. Here, working with expert rapid prototyping manufacturers becomes an essential place. Greglight stands out:

- Expertise on micro precision: They have advanced manufacturing technology, including complex SLM 3D Printerspecifically calibrated for complex features and materials.

- Material mastery: Extensive experience working with demanding metal powders (SS316L, titanium, Al Alloys) and engineering plastics ensures optimal printability and final partial characteristics.

- End-to-end solution: From design consulting (DFM-manufacturing recommended design) to printing, comprehensive Post-processingand finished (smoothing, polishing, gilding, painting), they provide a worry-free one-stop service. You will get the charm of ready.

- Quick customization: They effectively handle complex geometric shapes and unique material requests, enabling true custom production without high costs or long waits.

- Quality and reliability: As a professional rapid prototyping company focusing on precision and durability, Greatlight offers parts designed for execution – ensuring your custom Jibbitz Charm shoots firmly, looks great, and lasts long.

Conclusion: Beyond ordinary charm

3D printed Jibbitz represents the forefront of personalized fashion accessories. This technology enables individuals and businesses to create charm only limited by imagination. While home printing provides an entry point for simple plastic design, it can achieve professional-grade durability, complex details or advanced metal finishes that require industrial-grade features and expertise. Work with professional manufacturers Greatwith its advanced SLM technology and comprehensive post-processing services, ensure your custom Jibbitz Vision becomes a high-quality, wearable reality.

Ready to change the crocodile with unique precision design charm? Explore the possibilities of custom 3D printing Jibbitz now!

Frequently Asked Questions about 3D Printing Gibitz (FAQ)

Q1: Can my home FDM 3D printer make Gibbets well?

A1: Yes, for simple PLA designs, but visible layer lines are expected. Focus on a sturdy design, ensuring that cleat pins are carefully designed (appropriate nozzle width), using high-precision settings and sand/paint for better finish. Details will be limited and durability may not match professional prints or resin/metals.

Q2: How strong is the 3D printed Gibbets in metal compared to plastic?

A2: Significantly stronger and more durable. SLM printed stainless steel or titanium Gibitz is almost indestructible under normal wear, far exceeding the durability of plastics or resins. They have a huge sense of superiority. The cleat pins are very powerful.

Q3: Are anti-slip pins a weakness? How do you make sure it doesn’t catch?

A3: it able Become a weakness in poor design or print. Professional metal SLM printing solves this crucial challenge. Manufacturers like Greatlight can optimize pin designs for metal powder bed fusion, precisely control parameters of dense material structures, and often use specialized post-processing to ensure that the PIN maintains its strength. The enormous difficulty in printing this tiny metal feature is exactly why their expertise is crucial.

Question 4: How long does it take to make a custom metal gibbet?

A4: Delivery times vary, but professional services are usually within 1-2 weeks. On Greatlight, effective metal printing, rapid prototyping optimization and simplified post-processing can achieve rapid turnover of customized metal parts that meet stringent quality standards.

Q5: What is the cost difference between 3D printing of plastic and metal Gibitz?

A5: Plastic/resin jibbitz (especially DIY or basic service prints) are much cheaper (usually $1-$10 per piece of charm). SLM Metal Jibbitz is a premium product due to material costs, complex machinery, expertise and intensive post-processing (especially working on small parts). Expected to be significantly higher (accomplished by size/complexity/material, over $25 per piece), which reflects advanced manufacturing and durability.

Question 6: What file format do I need to customize production?

A6: Industry standards are step files or parasite files, but always convert your files to industry standards. Steps or parasite files are usually the first choice for containing design trees and native model data. However, Greatlight and similar services will require precise digital models in closed/solid formats to clearly define the surface. Step geometry file. *Always confirm specific requirements with the manufacturer.

Question 7: If I only have one idea or 2D sketch, can Greatlight provide design support?

A7: Absolutely. Well-known rapid prototyping companies such as Greatlight provide designs for Manufacturing (DFM) services. Their engineers can review the concept, create manufacturable 3D models based on sketches, propose optimizations for the 3D printing process, and ensure that Jibbitz designs will be functional and efficiently produced.