Click Revolution: How 3D Printing Reshapes Gonggi’s Classic Game

In the whole of East Asia, rhythmic Click string Gonggi (also known as Gonggi Nori, Kongki Nopi or five stones) responded in the playground and in the house. This deceptive and simple game, paired with five small star-shaped pieces of plastic, is abandoned and captured with skill and speed, is a beloved cultural touchstone. But under the charm of nostalgia is a surprising new boundary: Additive manufacturing or 3D printing.

We witness a quiet revolution in which the ancient game is transforming, not by giving up tradition but by embracing cutting-edge technology. Gonggi in 3D printing is not only novelty. It represents a custom, innovative and engaging evolution driven by the unique features of modern manufacturing.

Why 3D printing Gonggi? Beyond nostalgia

Traditionally, Gonggi fragments were mass-produced from injected plastic. This works great, but it fixes the game to unify. 3D printing destroys these limitations:

- High quantification: Want heavier fragments to satisfy? A lighter fast playback? Special texture for enhanced grip? Larger beginners or smaller, complex challenge design? 3D printing allows precise control of material distribution, density and geometric shapes for individual player preferences. Imagine a personalized kit with unique weights that can be adjusted for optimal flips.

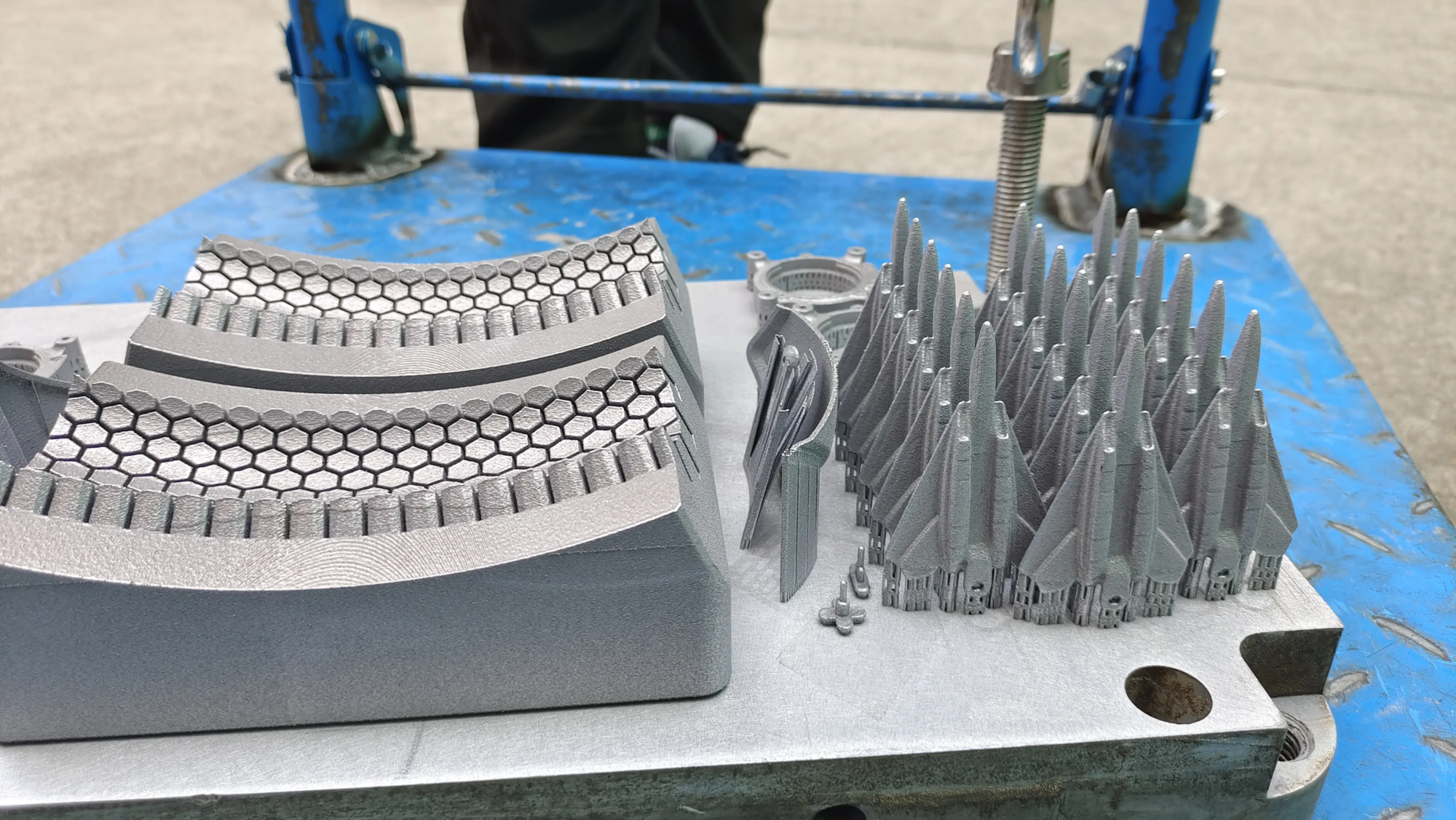

- Material Innovation: In addition to standard plastics (PLA, ABS), 3D printing opens the door to a brand new sensory experience. Print Gonggi nylon Create incredibly durable, lightweight pieces that can withstand intense gameplay. Engineered resins can provide unique elastic properties or crystal clearness. Crucially, for manufacturers like Greatlight, Metal 3D printing by selective laser melting (SLM) Unlock advanced possibilities. Imagine Lightweight titanium alloy – Incredibly strong, very dense, for a quality feel, resists permanent scratches and has unparalleled sound characteristics when hitting each other. Aluminum powder alloys offer another durable metal option. These materials will gongs go far beyond the inconspicuous plastic origins.

- Ergonomic exquisite: 3D printing helps create debris of surfaces with optimized grip and capture. Subtle ridges, specific curvature profiles, and even strategic matte/textured finishes (which can be achieved in post-processing) can significantly enhance player control, especially in complex multi-piece operations.

- Rapid prototyping and design iteration: 3D printing is priceless for game designers, engineers or enthusiastic amateurs. Test new shape changes? Adjust internal weight distribution? Evaluate new surface patterns? Prototypes can be printed in hours or days, tested, and then immediately improve the next iteration in CAD software. This agility is unimaginable to traditional tool approaches.

- Complex geometric and artistic expression: Injection molding struggles with highly complex or hollow geometric shapes. 3D printing flourishes on them. Gonggi pieces can have beautiful internal lattice structures (precise weight control), incorporate personalized prints or logos internally, or take a completely novel art form while maintaining their gameplay functionality. The potential of blending art and gaming is huge.

Technical Advantages: Making Advanced 3D Printing Gonggi possible

Create a gong work look OK, function is one thing. Create fragments Compete with or exceed The performance and durability of mass production versions require profound manufacturing expertise. Here is the light of advanced rapid prototyping technology:

- Precision Engineering: The geometry of each piece of jewelry directly affects its flight, stability during landing, and interaction with other debris. Huge utilization Advanced SLM 3D printer Ability to produce parts with special dimensional accuracy (<0.1mm tolerance) and complex internal features required to optimize weight distribution or specific acoustic characteristics. Consistent, high-quality printing ensures that every part of the set is uniform.

- Materials Science Expertise: Choosing the best material, whether it is a specific polymer or a high-grade metal powder, is crucial. This requires understanding of material properties: density, impact force, surface friction, acoustic properties and biocompatibility (for safe handling). For metal printed metals (such as titanium (TI6AL4V), aluminum (ALSI10MG, ALSI7MG)) or specific steel alloys, precise control of melting parameters is required to achieve the necessary strength to weight ratio and surface finish required for smooth gameplay.

- Surface mastery: Original 3D printed parts often require post-processing. Here, capabilities such as precision blasting (e.g., fine sand or glass beads), tumbling, vibration polishing, hand-fueling, and potentially professional coatings become essential. For Gonggi:

- Polymer Printing: Smooth to eliminate layer lines (to ensure predictable bounce/capture), careful texture or matte finish.

- Metal Printing (SLM): A lot of post-treatment is required, such as stress reduction, removal of support structures, precise machining and grinding, to achieve the desired surface smoothness, tactile feel and aesthetic quality. Service providers like Greatlight and integrated One-stop post-processing function It is crucial to delivering a flawless, i.e. playable metal gong kit.

- Proportion and repeatability: Advanced rapid prototyping is more than just one-off. Reliable high-precision printers and strict quality control processes allow manufacturers to produce small custom batches or larger production runs while maintaining strict consistency – crucial must Behavior the same.

Innovative sound: Acoustics is important

The often overlooked aspect of Gonggi is justified. feature Click,,,,, naggingand roar It is an integral part of the rhythm of the game and the feedback from players. Different materials and internal structures greatly change these sounds. Metal fragments (such as titanium) produce transparent, resonant, treble "ping" or "Ting," Unlike the dim plastic sound. Nylon creates a gentle sensation. Accurate 3D printing allows fine-tuning of internal structures such as controlled fill density or lattice design to achieve a specific resonant frequency or attenuated vibration, resulting in intentional acoustic design at impossible levels in the case of solid injection molding. This creates a unique auditory signature for the custom set.

Beyond the Game: Cultural Meaning and Preservation

3D printing provides innovative methods for cultural literature and preservation. Detailed 3D scans (traditional handmade wood or stone variants) can be captured and printed with durable materials to capture durable materials, creating accessible replicas for museum or educational purposes. This bridges the gap between physical gameplay and intangible cultural heritage.

Conclusion: Eternal Games are in line with tomorrow’s technology

3D printed Gonggi not only replaces plastic. It uses materials that were previously unavailable to the game manufacturer to unlock unprecedented customization, durability, and performance. From the lightweight, elastic nylon set to the premium weight and sound clarity of titanium chips created through SLM, additive manufacturing allows us to reimagine this traditional game of the modern era.

The revolution lies in the integration of nostalgic gameplay with advanced engineering and manufacturing capabilities. For manufacturers like Greatlight, have expertise High precision rapid prototyping using SLM and other leading technologies, coupled with comprehensive post-processingthe potential is huge. We can create a:

- Personalization: Precisely tailored to individual needs and desires.

- Enhanced: Optimized for performance, feeling and longevity.

- Innovative: Explore new materials, textures and acoustic experiences.

- Durable: To endure years of passionate games.

Whether you are rediscovering childhood games, introducing them to a new generation, or being fascinated by the intersection of tradition and high technology, the 3D-printed Gonggi represents an exciting evolution of timeless classics. Iconic Click string Now comes with precisely manufactured echoes.

FAQ: 3D Printing Gonggi

- Are 3D printed Gonggi works as durable as traditional plastic? They can More Durable. Use engineering plastics such as nylon (PA) or advanced metal alloys (titanium, aluminum) to generate fragments that are highly resistant to debris, cracks or wear through processes such as SLM. They are excellent in impact resistance.

- Which material is best for 3D printed Gonggi?

- plastic: Nylon (PA 11, PA 12), which can be lightweight, durable, flexible; PETG or ASA, which can be replaced with strong and slightly harder.

- Metal: Titanium alloy (TI6AL4V) for top-notch advanced feel, sound and intensity weight; aluminum alloy (ALSI10mg) has excellent durability and is lighter in weight than stainless steel. The choice depends on the weight, feeling, acoustic preferences and budget required. Greatlight specializes in these high-performance metal materials.

- Can 3D printed Gonggi works be heavier? Absolutely! This is a key advantage. For polymer prints, denser fill patterns and strategic solid layers add weight. Metal printing naturally uses intensive materials. The design can be combined with internal structures to concentrate mass while maintaining consistent shape and rebound characteristics.

- How do you achieve a smooth, playable surface, especially metal prints? Post-processing is crucial. Original 3D printing requires a finish. On Greatlight, this involves techniques such as precise machining of critical surfaces, custom sand blue routines with specific media sand particles, which can tumbling and sometimes specialized printing orientation/settings to minimize initial roughness. This ensures that the touch meets the needs of gameplay. For SLM metal parts, this process is included in our one-stop solution.

- Can I customize the appearance of 3D printed Gonggi? Yes! In addition to colors, you can customize your geometric design (add subtle patterns, logos), select different surface textures (smooth polish, matte, light explosion), and mix colors in a single piece using a dedicated multi-matter printing method (less common, but possible).

- Can I make a custom 3D printed Gonggi suite? Yes. Professional rapid prototyping service services like ours specialize in creating custom designed Gonggi suites. You can specify materials (from advanced polymers to metals like titanium or aluminum), the required weight range, the finish (for example, a smooth polish for metal, the grit texture used for the grip), and maybe even personalized elements. Greglight provides end-to-end precision manufacturing services and consulting for such customized projects.

- Can metal Gonggi parts be handled safely? Yes, when professionally manufactured. Post-treatment can remove any sharp edges or sintered particles. Metals such as titanium and aluminum are biocompatible alloys. The smooth, polished or blasted finish achieved by the service provider ensures a comfortable and safe handling.

- How does the sound of a metal gong compare to plastic? Metal fragments produce unique, clearer, and more resonant "ping," "Ting," or "clink" When they collide or land sounds. Plastic usually makes a soft "Click" or "roar." This acoustic difference can be an ideal quality feature and can be ingeniously influenced by the internal design and the particular metal selected. Titanium has a particularly unique treble ring.

GRESTHERMENG: Your Precision Game Innovation partner

At Greatlight, we not only build parts; we help shape the experience. As a professional Rapid Prototyping Manufacturer Equipped with the latest SLM (Selective Laser Melting) 3D Printer With comprehensive manufacturing expertise, we specialize in solving complex complex complexes Rapid prototyping of metal parts challenge. Our overall approach includes One-stop post-processing and completion servicemake sure your vision (whether it’s a super-cliented Gonggi set or other demanding applications) is transformed from digital models to perfect physical reality.

We understand the complex requirements of functional components, especially for haptic products (such as gaming), accuracy, weight, balance, surface feel and material performance. From proof of concept to functional prototypes to scalable low-volume production runs, Custom precision machining exist The best price No compromise on quality or innovation.

Innovate your game. Customize your Gonggi experience. Explore the potential of advanced manufacturing with Greatlight – one of the best rapid prototype companies in China.

Customize your precision speed prototype parts now! Contact us to discuss your project.