Unlocking Innovation: Accuracy and Potential of 3D Printing Gravity Knife Guide

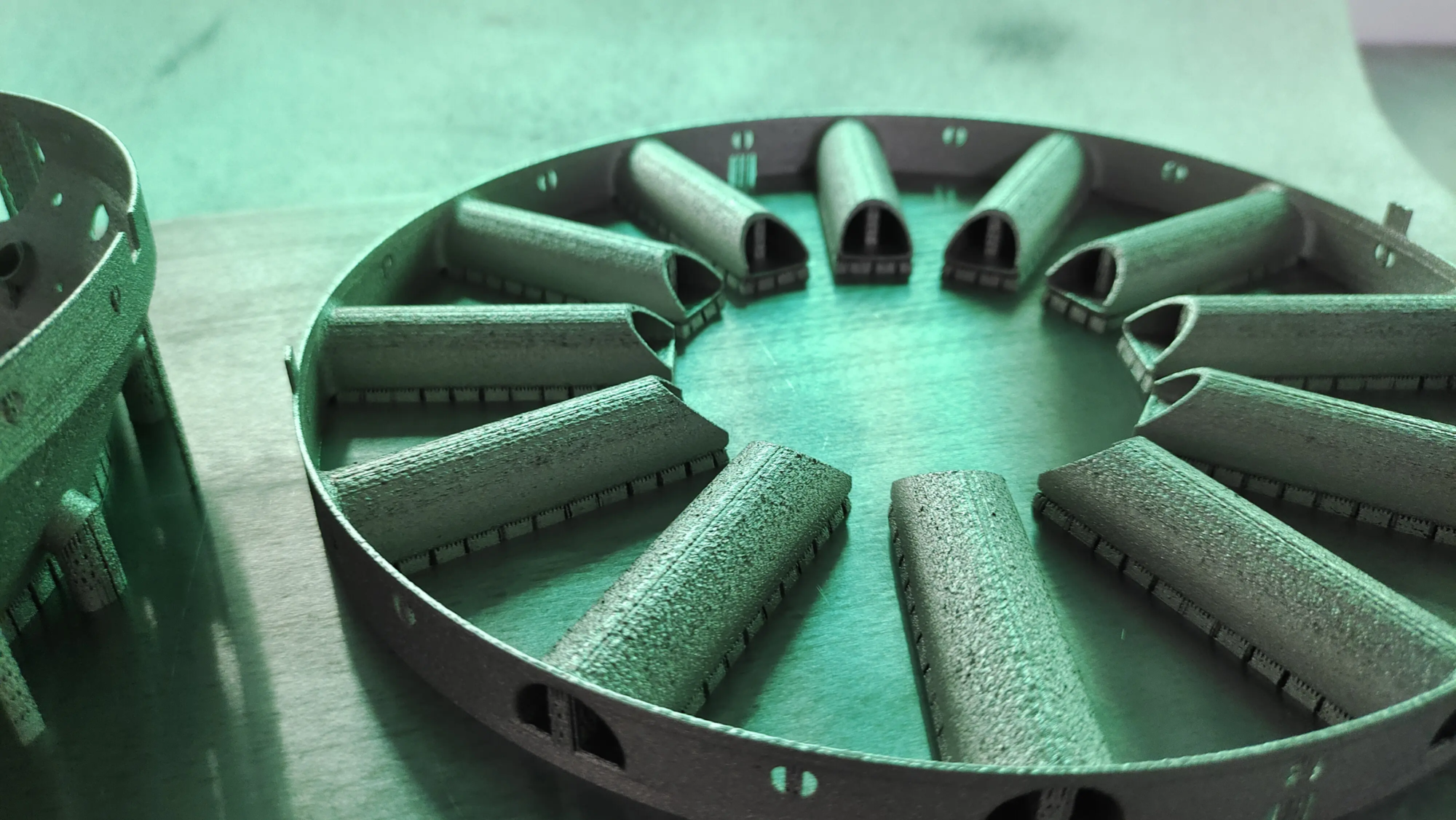

Due to additive manufacturing, the field of tool manufacturing, especially fixtures and fixtures, is underway for a quiet revolution. The 3D-printed Gravity Knife Guide embodies this transition – beyond simple prototypes to create highly functional precise production tools. Once crafted by labor-intensive subtraction methods, these guidelines can now be designed and produced with significant speed, complexity and cost-effectiveness using advanced 3D printing techniques. But what exactly is the gravity knife guide and why 3D print the keys to unlock its potential? Let’s dig into design, engineering and manufacturing advantages.

What is a Gravity Knife Guide? Beyond the blade

First, it is crucial to clarify the context. Gravity Knife Guide is Not the knife itself. This is manufacturing,,,,, assemblyor Quality control Gravity knife mechanism or blade housing. Its main functions usually include:

- Alliance: Ensure the pivot point of the blade, precise positioning of the locking mechanism assembly, and handle the perfectly-moving parts.

- Conference support: When pressing the pin, tightening the screw or adjusting mechanism, securely secure the delicate parts in place.

- Actuation test: Provides a consistent frame to test the smooth opening/closing function and locking reliability of the tool mechanism to be assembled.

- consistency: Ensure that every knife produced in the User Guide complies with the same dimensional tolerances and functional standards.

Traditionally, these guidelines have been processed from metal blocks, require high expertise, a lot of machine time, and can be expensive and inflexible.

Advantages of 3D printing: Converting fixture production

By leveraging technologies such as selective laser melting (SLM), multi-jet fusion (MJF), or high-speed stereoscopic gloss (SLA), manufacturers can overcome the limitations of traditional methods:

- Unparalleled design freedom and iteration speed: Complex internal channels of assembly tools, ergonomic handles for operator comfort, integrated alignment capabilities, and lightweight lattice structures can be easily achieved through 3D printing. Need to adjust the tolerance or add mounting points? CAD updates and new prints replace rescheduled days. This agility is very valuable for rapid prototyping and Adapt production guide.

- Cost-effective (especially for low capacity and prototype): Eliminate expensive tools (molds, fixtures for machining) and greatly reduce machine time, making 3D printing ideal for initial production runs, custom/professional tools and prototype verification tools. Cost and quantity are scaled linearly.

- Precision of matching processing: Advanced industrial printers, especially SLA and metal SLM systems, achieve micron-scale resolution and excellent dimensional accuracy. Combined with precise calibration, they produce guidelines that meet the tight tolerances (<±0.1 mm) required for the tool mechanism to operate in full.

- Customized material properties:

- Rigid, wear-resistant plastics (e.g., nylon PA12 -MJF, PP -SLS, high temperature resin): Provides excellent stiffness, good impact and sufficient wear life for many assembly and testing cycles. Ideal for most guide apps.

- Engineering Metals (Stainless Steel, Tool Steel, Aluminum Alloys by SLM): In demanding production environments, extremely high accuracy or high thermal properties are required for ultimate durability. Greatlight’s SLM functionality shines here, creating a powerful dense metal wizard directly from CAD.

- Lightweight but very strong: Printing guides, especially those using lattices or optimizing topology, achieve excellent strength-to-weight ratios. This reduces operator fatigue in assembly lines and simplifies processing.

- Integrated features: The screw boss, fixture locator, key slot, channel for pneumatic lines or sensors can be integrated directly into the design, simplifying the final guide setup.

GRESTHELLE: Your partner for innovation in precision tools

At Greatlight, we specialize in transforming complex design concepts into high-performance reality. Our expertise Manufacturing of industrial grade additives Perfectly positioned us to provide an excellent guide to 3D printed gravity knife:

- Advanced SLM features: For applications requiring ultimate durability, accuracy and stability (thermal/mechanical), our selective laser melter can produce fully dense stainless steel (316L), tool steel (H13) or aluminum alloy guide. These metal guides are perfect for high-volume production lines where life is critical.

- High-performance polymer solution: Using technologies such as nylon PA12 or technology fusion (MJF) such as Ultratem® Pekk and industrial grade SLS/SLA, we have created a powerful plastic guide with good surface effect, dimensional stability, and common oils/greases in assembly environments.

- Engineering and design support: Our team works for functional and manufacturing optimization guides – suggesting material selection, orientation, critical tolerances and potential reinforcements.

- Complete post-processing suite: We don’t just print the parts; we’ve finished them. Expect options such as: fixed/firing (metal), vapor smoothing (plastic), precision machining of critical sealed surfaces, custom finishes, textures, dyeing, dyeing or clear coatings for protection and identification.

- One-stop prototype production and production: From the initial proof-of-concept prototypes of plastics to hardened steel production tools for factory flooring, Greatlight offers a seamless integrated solution. We’re good at Quick turnaround Uncompromising the quality or accuracy required for tool application.

Material Notes for Guidelines: Greatlight exceeds

| Key Requirements | Recommended material options | Greglight Solutions | Ideal application |

|---|---|---|---|

| High wear resistance/durability | Stainless steel (316L SLM), tool steel (e.g. H13 SLM), PEKK (Ultem®) | SLM metal printing, industrial SLS/powder printing | Large-scale production assembly line, solid test fixture |

| Dimensional accuracy and complex details | Engineering resin (high temperature), nylon PA12 MJF/SLS | High resolution SLA, MJF, SLS | Prototype verification, fixtures requiring fine functions |

| Good strength to weight and impact resistance | Nylon PA11/PA12 (SLS/MJF), similar to ABS-like resin | SLS, MJF, Advanced SLA | Conference Guide, Handling Fixtures |

| Chemical/Electric Oil Resistance | pp-like material (SLS/NJF), ABS-like resin, peep/PEKK | Industrial SLS/powder printing, SLM metal | An environment exposed to lubricants or detergents |

| Cost-effective (prototype/low volume) | Nylon PA12 (MJF/SLS), resin | MJF, SLA, SLS | Initial prototype, low to medium yield |

| Structural integrity/rigidity | Aluminum alloy (SLM), filler resin, Beijing | SLM Metal Printing, Advanced SLA, High Performance Polymer | Large structural guide, requiring minimal flexibility |

GREMLIGHT has deep expertise in materials science and process optimization. We help you browse these options to choose Optimal materials and processes For the specific performance and economic requirements of your tool.

The Future of Printing Tools

The 3D-printed gravity knife guide is just a valid example of how additive manufacturing can reshape industrial tools. It goes beyond fast prototyping, and it provides a faster, more adaptable, and often more cost-effective way to create precise fixtures that are essential for manufacturing quality components. By including complex geometry, integrating functions, enabling rapid iteration and leveraging high-performance materials, from advanced polymers to fully dense metals, 3D printing pushes the boundaries possible in tool production.

in conclusion

The 3D printed gravity knife guide represents a significant leap in the efficiency and capability of knife manufacturing tools. Gone are the days that are limited by the traditional machining limitations of these complex fixtures. Advanced 3D printing technologies such as SLM, MJF and SLS provide the flexibility, speed and design freedom to create superior tools for assembly, alignment and quality control. At the forefront of this transformation, Greatlight combines state-of-the-art equipment, expertise in materials and deep manufacturing expertise to provide customized high-precision guides for durable metals or engineered plastics. Whether you need to design a proven prototype quickly or hardened steel tools for mass production, 3D printing offers a powerful forward-looking solution. Work with Greatlight to design and manufacture precise tools to improve your knife production process.

FAQ: 3D Printing Gravity Knife Guide

-

Q: Is 3D printing powerful enough to be used like a gravity knife?

Answer: Absolute. Using industrial grade materials and processes is key. Durable thermoplastics such as nylon PA12 (via MJF/SLS) or Ultem Pekk provides excellent stiffness and wear resistance for many cycles. For extreme durability in high volume settings, metal options such as stainless steel or tool steel printed by SLM can be compared with traditional mechanically processed metal guides. -

Q: What is the accuracy level of 3D printing guides?

one: Advanced industrial printers (especially SLA and SLM) achieve high dimensional accuracy, usually at ±0.1 mm (±0.004 inches) or higher, depending on the specific technology, material, part size and printer calibration. Precision-processing key surfaces such as post-processing can further improve accuracy when needed. -

Q: Are 3D printed metal parts porous? How does this affect the guide?

one: Selective laser melting (SLM) technology produces parts with close to 100% density when correctly calibrated and leveraged optimized build parameters. This density gives them mechanical properties (strength, stiffness, wear resistance) that can be comparable to, even exceed, casting or even equivalents. Greatlight uses strict process controls to ensure optimal density and material integrity. -

Q: How does the cost compare to the CNC machining guide?

one: 3D printing often wins costs, especially:- Complex design: Due to reduced fixation and tooling requirements, highly complex geometries are often cheaper than machines.

- Low to medium volume: Eliminate tool/setup costs to make printing cost-effective for prototypes and small batches.

- Iteration: The cost of design changes greatly reduces printing.

For simple geometry of very high rolls, traditional CNC machining may be cheap, but 3D printing has the advantage of flexibility.

-

Q: What is the typical turnover time for such a part?

one: Speed is the main advantage of 3D printing. Although complex metal SLM parts take longer (due to building speed and heat treatment), many polymer guides can be printed, completed and transported in a few days. GRESTLIGHT specialized research Rapid prototypingso even sophisticated metal guides made through SLM can be delivered faster than traditional tools. - Q: This guide used to be Production Illegal knife?

one: Gravity Knife Guide is a manufacturing/assembly tool. Its main function is to produce components (mechanism/shell) and ensure assembly consistency and quality. This is not the knife itself. Greatlight provides manufacturing services for precision parts and tools in full compliance with applicable laws and regulations. legality Finished product (Knife) is entirely dependent on the local laws it designs, sells and owns – it is the responsibility of the knife manufacturers and end users.

Work with your next precise tool challenge. Create innovative high-performance guides and fixtures with our advanced SLM metal printing, industrial polymer capabilities and complete post-processing services. Get a quote for custom 3D printed parts now!