Bring Magic to Life: Make the Perfect 3D Printed Mickey Mouse

Mickey Mouse has been a global idol for decades and can be identified immediately and cherished deeply. Today, 3D printing technology enables fans and creators to bring this beloved character from the screen and into the physical world that has never been seen before. Whether you are a fan who wants a unique desktop companion, a designer creating prototypes for a themed product, or a collector looking for a custom work, it opens up incredible possibilities. This guide delves into the complexity of creating a stunning 3D printed Mickey mouse, highlighting key stages and how expertise can improve the end result.

Digital Blueprint: From Pixels to Prototypes

Everything starts with high quality 3D models. Finding the perfect Mickey Mouse digital model requires careful consideration:

- A wise source: Famous repositories such as Thingiverse, Cults3D or myminifactory offer a variety of designs, usually classified by style (classic, modern, stylized) and complexity. Make sure the file is printable (supported watertight grid). For truly unique or prototype designs, skilled 3D modelers create custom models from scratch based on specific requirements.

- Energy Software: Modify the design, add support structures, or optimize for printing requires software. Beginners can use user-friendly tools like Tinkercad, while professionals use blenders, Zbrush, or Fusion 360 for sophisticated details. Correctly scaling the model correctly is essential for the expected application to scale.

Material Problem: Choose Mickey’s Makeup

The choice of materials greatly affects the appearance, feel and function of 3D printed Mickey:

- PLA: The first choice for enthusiasts. Affordable price, easy to print in all colors (very suitable for Mickey’s classic red shorts), and environmentally friendly. Best for decorative models.

- ABS: Stronger and more heat resistant than PLA, but requires a controlled environment (heating bed, housing) to prevent warping. Suitable for models that require additional durability.

- PETG: Compared with PLA, the ease of use of printing is combined with increased toughness and chemical resistance. A great all-round character that can achieve a stronger character.

- Resin (SLA/DLP): Provides excellent surface smoothness and captures tiny details – ideal for high-fidelity figurines, jewellery or intricate decorations. Ideal for capturing Mickey’s expressive traits. Needs post-treatment (washing and curing).

- Metal: Advanced Conversion: This is where the product enters Heirloom quality and industrial applications. use Selective laser melting (SLM)high-power lasers fuse fine metal powder layer by layer. Imagine a small statue of Mickey Mouse, dressed in polished stainless steel, lightweight but sturdy aluminum, and even titanium. Metal printing produces parts with excellent strength, unique aesthetics and impressive durability. (This feature is the cornerstone of Greatlight expertise.)

The Art and Science of Printing

Different techniques bring Mickey to life:

- FDM/FFF: Common desktop printing. The layer is extruded. Need tricks to minimize layer lines, but accessible and universal.

- SLA/DLP: Use light-cured resin. Achieve superb details – Great for small, sophisticated Mickey models, keychain or jewelry prototypes.

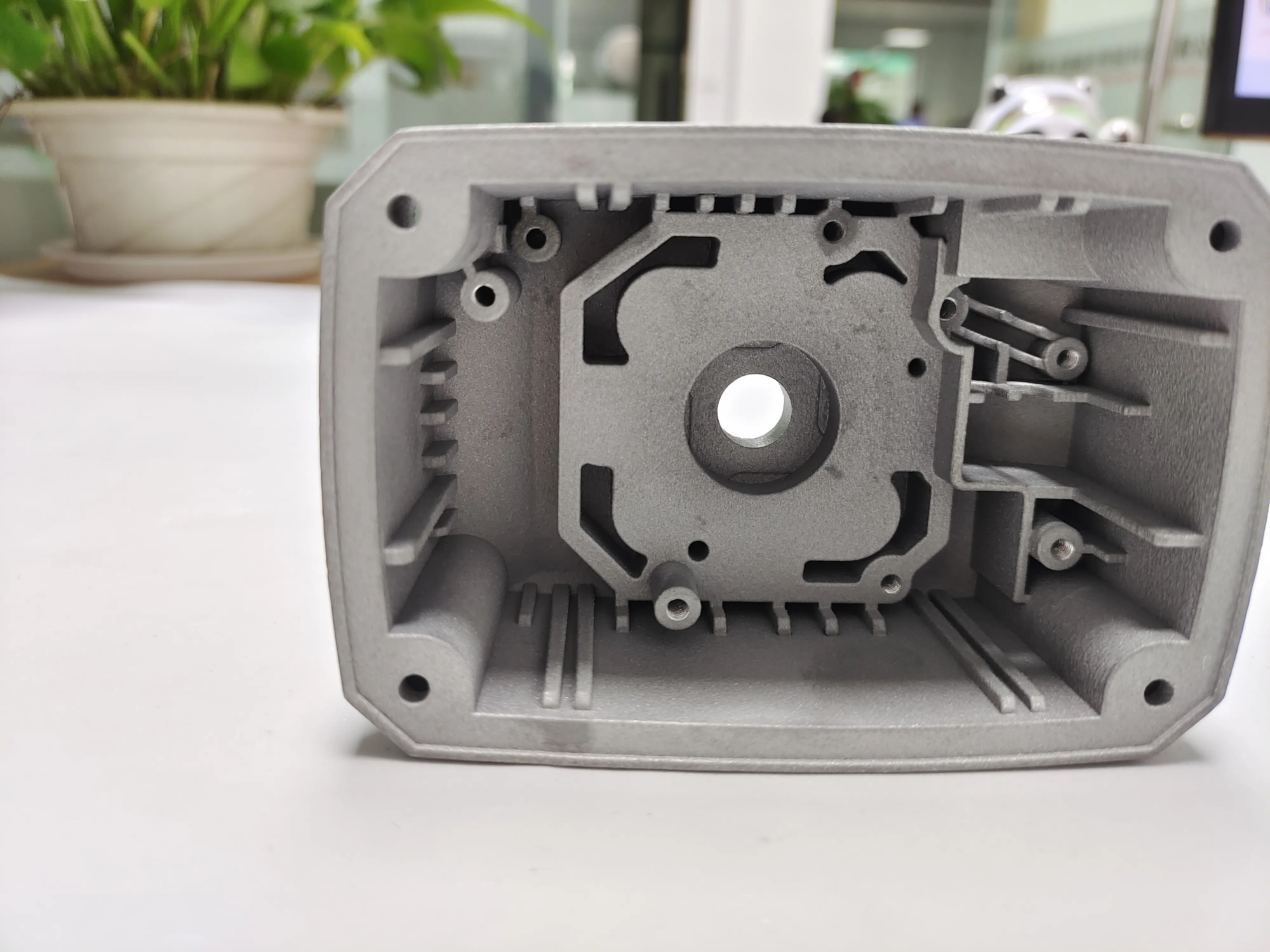

- SLM: Industrial Metal Proficiency: For unrivalled strength and material properties, SLM is unparalleled. It transforms digital Mickey into a structural integrity that works for functional prototypes, high-end collector projects, and even character-inspired custom mechanical components (e.g., dedicated knobs or housings). The technology requires advanced industrial equipment and important process expertise to manage the high temperature, inert atmosphere and complex parameters involved. Companies like Greatlight specialize in leveraging the power of SLM and other advanced metal printing technologies.

Beyond Print: The Critical Stage of Post-processing

Original 3D printing almost always needs to be done to achieve a professional look and functionality. This is the real area where professional services are truly shining:

- Support removal: Carefully remove temporary support structures (critical for complex postures) without damaging the model.

- Grinding and polishing: Smooth the layer lines (especially on FDM printing) or prepare resin/metal surfaces for final finishing. Patience and skill are required to make curves and details.

- Start and Painting: To achieve Mickey’s vibrant, accurate colors require proper surface preparation, primer, skilled painting (including covering up clean lines) and seals. The spray gun provides the smoothest gradient.

- Metal finish: Metal parts have unique finishing options:

- Grinding/Explosion: Achieve the required surface roughness.

- Processing: Add threading or precision function to print.

- polishing: Mirrored and satin finishes.

- plating: Coated with gold, chromium, nickel, etc.

- Anodized (aluminum): Add a durable, colorful finish.

- Greatlight emphasizes its complete post-processing service, bringing metal parts from their original printed state to a fully functional or beautiful masterpiece.

Why 3D print your own Mickey?

- Custom: Mass production of unique stylized postures, personalized sizes or material choices that are impossible. Want a chrome deco art deco Mickey? 3D printing makes it feasible.

- prototype: Designers can improve product creativity (toys, collectibles, decorative elements) quickly and cost-efficiently before committing to expensive manufacturing tools. Both plastic and metal prototypes are priceless.

- Collections and Gifts: Create truly unique works with sensual or artistic value.

- educate: Learn about 3D modeling, printing techniques and completion techniques.

- Functional application: Metal Mickey prints can be used as durable knobs, unique connectors or stylized covers for niche industrial or luxury customization applications.

in conclusion

The journey of creating a 3D printed Mickey Mouse seamlessly blends nostalgia with cutting-edge technology. From sourcing the ideal digital model and choosing the right material (whether it’s the dynamic plastic of the desktop figure or the powerful metal used to state the material) to browsing the complexity of printing and the transformative power of expert finishes, every step is crucial. While desktop printing can enable hobbyists to achieve truly professional, durable or complex results, especially in metals, industrial-grade equipment and expertise are required.

For those looking for high fidelity, powerful and impeccable finished work, whether it’s for prototypes, collectibles or featured applications – it’s crucial to work with experienced rapid prototyping experts. Greatlight stands at the forefront, leveraging advanced SLM 3D printing technology and comprehensive internal post-processing capabilities to turn the complex Mickey Mouse concept into reality. Our expertise ensures that your vision is not only printed, but perfect, meeting the highest standards of precision and quality regardless of the material you choose.

FAQs about 3D printing of Mickey Mouse

-

Is 3D printing and selling Mickey Mouse’s body legal?

- Mickey Mouse is a copyright and trademark character owned by Walt Disney Company. Print the figure of Mickey’s mouse For personal, non-commercial use (for example, as a decor in your home) is generally considered acceptable under the principle of fair use of copyright in many jurisdictions. However, Sale or distribute 3D printing of Mickey without Disney’s explicit permission is copyright and trademark infringement and illegal. Always respect intellectual property rights.

-

What is the best 3D printer for making Mickey Mouse characters at home?

- for High-detailed and smooth surface: Resin (SLA/DLP) printers are the preferred choice, especially for figurines.

- for Ease of use and cost-effectiveness: FDM printers using PLA are perfect for beginners or larger decorative models. Priority is given to printers known for their good resolution and reliability.

-

Why do I choose metal for a 3D printed Mickey mouse?

- Durability and Permanence: Metal parts are significantly stronger and more durable than plastic, suitable for functional prototypes, long-lasting collectibles, or applications requiring weight and elasticity.

- Unique aesthetics: Metals have a premium, unique look and feel – polished stainless steel, anodized aluminum, and even brass/bronze finishes, which prevent the plastic from getting a stunning visual impact.

- Functional properties: Metals are crucial for applications requiring conductivity, heat resistance or specific mechanical properties.

-

How does SLM metal printing work and why does it matter?

- SLM (Selective Laser Melting) uses a high-power laser to selectively fuse fine metal powder in an inert atmosphere and build parts layer by layer. It produces fully dense high-strength metal components with complex geometries that cannot be manufactured using traditional methods such as processing or casting. This allows for complex designs such as detailed metal Mickey with internal structure.

-

What are the completion options for 3D printing of Metal Mickey?

- Professional post-treatment options are a wide range of: grinding, matte (for texture), precise CNC machining (for key features), high polishing for mirror finishes, various gold plating techniques (gold, chrome, nickel), anodizing for aluminum (added color), powder coatings, etc. Companies specializing in metal AM, such as Greatlight, provide comprehensive completion services to achieve the exact desired appearance and functionality.

- I need high quality metal Mickey mouse prototypes/collections. How does Greatlight help?

- Provided by Greghime End-to-end solution:

- consult: Discuss your design, material selection (stainless steel, aluminum, titanium, etc.) and completion requirements.

- Advanced Printing: Leverage industrial SLM machines to produce your complex, high-strength metal Mickey components.

- Experts completed: Apply all necessary post-treatment (support disassembly, heat treatment, machining, polishing, plating/anodizing) to meet the precise specifications.

- quality assurance: Ensure that the final product meets dimension accuracy and quality standards. Please contact Greatlight for a quote to bring your premium metal Mickey project to life.

- Provided by Greghime End-to-end solution: