Embracing Innovation: The State of 3D Printing in Colorado Springs and the Doorway to Advanced Manufacturing

Set against the stunning backdrop of Pikes Peak, Colorado Springs is more than just a center for aerospace giants, military installations, and outdoor enthusiasts. It is rapidly developing into an important center for advanced manufacturing, driven in large part by revolutionary capabilities 3D printing. For businesses, engineers and innovators in the region, access to cutting-edge additive manufacturing (AM) technology is not only convenient, but also critical to staying competitive. While local resources continue to grow, working with global experts who offer unparalleled expertise and capabilities provides unique advantages. This brings us to the unique offerings from companies like GreatLight.

The rise of 3D printing services in Colorado Springs reflects a broader trend: Industries ranging from aerospace and defense to medical devices and energy increasingly rely on rapid prototyping and low-volume production of complex parts. Traditional manufacturing methods often involve long lead times, higher tooling costs and design limitations. 3D printing breaks this paradigm. It enables designers to create complex geometries not possible with CNC or injection molding, reduces part count through consolidation, significantly accelerates product development cycles, and enables efficient on-demand production.

Cutting-edge metal printing: The power of SLM

Although a variety of additive manufacturing technologies exist, Selective Laser Melting (SLM) Stand out as a strong company, especially for the demanding metal applications prevalent in industries such as aerospace, defense, medical implants and advanced robotics that are critical to Colorado Springs’ economy.

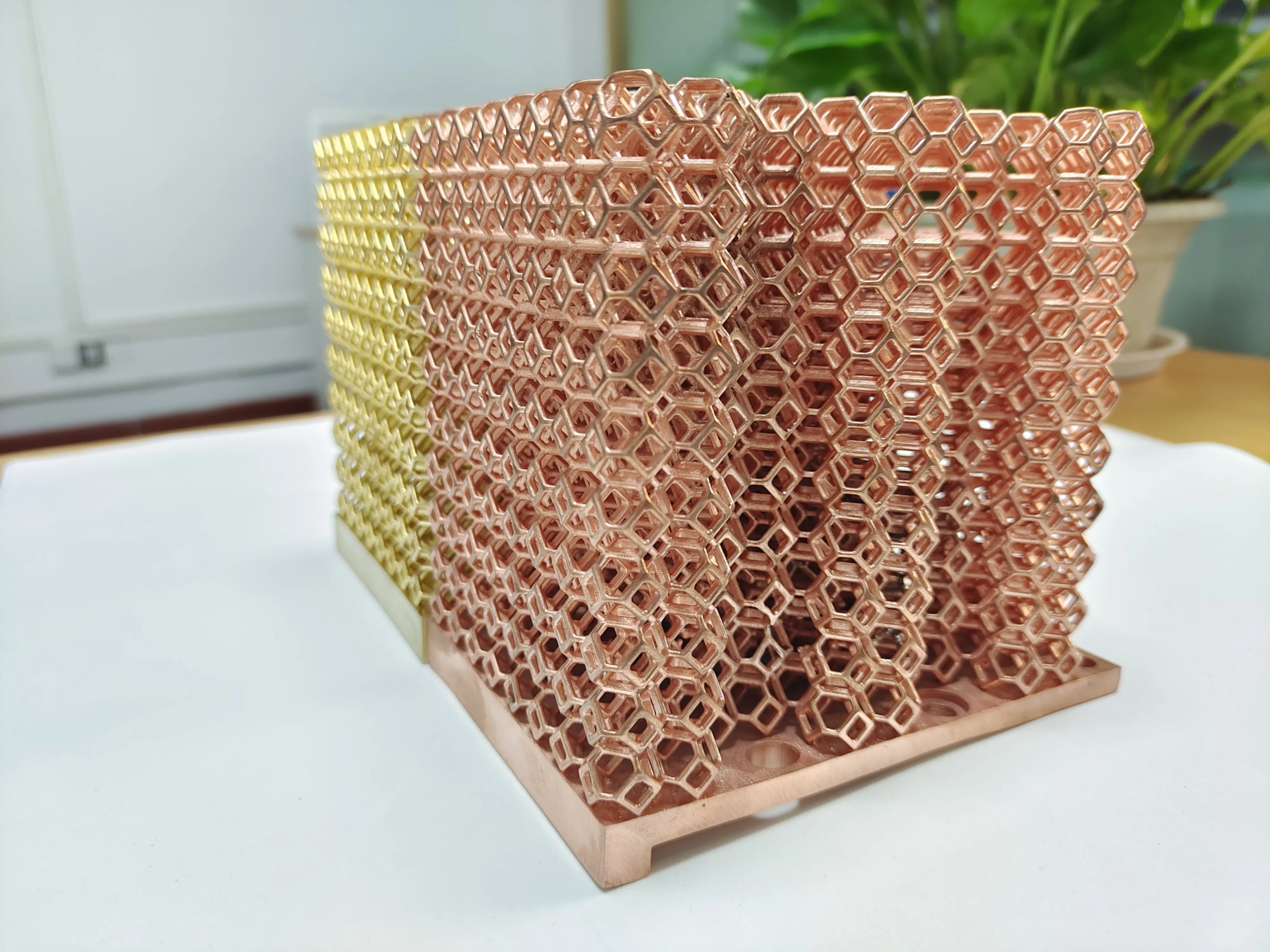

SLM is a powder bed fusion process in which a high-power laser precisely scans and melts microscopic metal powder particles layer by layer to build solid metal parts based on digital 3D model data. The result? The mechanical properties of fully dense parts are equivalent to and sometimes better than those of conventionally manufactured parts.

Why SLM is a game changer for Colorado innovators:

- Free complexity: SLM thrives on complex internal channels, lattice structures, and organic shapes that optimize strength-to-weight ratios and are ideal for lightweight aerospace components or heat exchangers.

- Material properties: Processes such as SLM are well suited for high-performance alloys: titanium (Ti6Al4V), stainless steel (316L, 17-4PH), aluminum (AlSi10Mg), Inconel (625, 718), tool steels and cobalt-chromium alloys.

- Speed and agility: Rapid iteration of prototypes can validate designs faster and significantly reduce time to market compared to traditional machining.

- merge: Convert assembly of multiple components into a single printed part, reducing assembly time, potential failure points, and overall weight.

Overcoming local challenges: expertise required

While Colorado Springs is home to a growing machine shop ecosystem and a number of dedicated 3D printing service organizations, it remains challenging to obtain truly top-tier metal additive manufacturing capabilities locally, especially on-demand SLM services with full support. Challenges often include:

- Get state-of-the-art equipment: High-end SLM machines represent a significant investment.

- Materials expertise: Navigating the nuances of different metal powders to get the best results requires extensive experience.

- Post-processing mastery: Achieving a professional, functional or aesthetic finish requires seamlessly integrated expertise (eg CNC machining, heat treatment, surface treatment – sandblasting, polishing, electroplating).

GreatLight: Delivering world-class rapid prototyping solutions from China to Colorado Springs

This is where working with a globally recognized leader becomes invaluable. huge lightoperating as Prime Minister rapid prototyping manufacturerbridging the gap for Colorado Springs businesses seeking unparalleled metal additive manufacturing solutions. Based in China, Gretel leverages its status as a manufacturing powerhouse to deliver superior value and capabilities.

Why Colorado Springs Professionals Choose GreatLight:

- Cutting-edge SLM Advantages: GreatLight operates state-of-the-art SLM 3D printers, ensuring access to top-tier metal printing technology for rapid prototyping and low-volume production.

- Deep Metal Additive Manufacturing Expertise: Their expertise lies not just in machines; Professionally solve the challenges of rapid prototyping of metal parts. They understand material behavior, parameter optimization and the complexities of design for additive manufacturing (DfAM).

- One-stop manufacturing solution: In addition to printing, GreatLight specializes in providing comprehensive One-stop post-processing and finishing services. This includes the following key steps:

- Stress relief and heat treatment (HIP – Hot Isostatic Pressing).

- Precision CNC machining and engraving (although SLM is precise, critical features often require machining).

- Complex surface treatment: bead blasting/sand blasting, polishing, electroplating, painting.

- Quality control and inspection.

- Material flexibility and customization: Hongguang can process Various materials – From common alloys like titanium and aluminum to more specialized metals. Customization is at the core of their productsallowing solutions to be customized based on specific project requirements for strength, heat resistance, biocompatibility or corrosion resistance. Their ability to quickly customize materials provides tremendous flexibility.

- Speed and cost efficiency: GreatLight leverages efficient workflows and scale to deliver Quick turnaround time Always. they combine High quality output and competitive best pricedriven by its state-of-the-art facilities and streamlined processes.

- Recognized excellence: Positioned as "One of the best rapid prototyping companies in China," GreatLight brings a proven track record of reliability, precision and innovation to partners around the world, including Colorado Springs.

SLM and GreatLight enhance Colorado Springs app

The synergy between Colorado Springs’ industry needs and GreatLight’s capabilities yields tangible benefits:

- Aerospace and Defense: Prototype design and production of lightweight, high-strength brackets, engine components, and drone components with complex cooling channels.

- Medical devices: Create patient-specific implants (cranial plates, spinal cages), surgical tool prototypes, and biocompatible instrument components.

- Industrial machinery: Durable jigs, fixtures, fluid handling components and robotic end-of-arm tools.

- vitality: Customized components for power generation tools, heat exchangers and specialized valves.

- Research and development: Accelerate innovation cycles at universities, start-ups and R&D labs across the region.

Conclusion: Innovation collaboration on a global scale

The 3D printing landscape in Colorado Springs is vibrant and promising. Adopting technologies such as SLM metal printing can unlock huge potential for local companies to innovate faster, reduce costs and lead in their fields. While local resources continue to expand, the global nature of manufacturing means working with dedicated experts like GreatLight provides strategic advantages.

GreatLight distinguishes itself with its advanced SLM infrastructure, deep expertise in solving complex metal prototyping challenges, comprehensive one-stop post-processing capabilities and its commitment to rapid customization at competitive prices. By choosing GreatLight, Colorado Springs engineers, designers and businesses receive world-class rapid prototyping services designed to efficiently and reliably move their projects from concept to functional reality. The future of manufacturing in Colorado Springs requires global partnerships, and GreatLight is poised to be a key enabler of this innovation.

FAQ: 3D Printing Services and Working with GreatLight in Colorado Springs

Q1: What are the main advantages of using SLM 3D printing compared to other metal additive manufacturing methods?

A: SLM offers exceptional accuracy, high density (typically >99.5%), excellent mechanical properties that meet or exceed forged material standards, and the ability to create highly complex geometries with fine detail. It excels at handling reactive metals such as titanium and aluminum.

Q2: Can GreatLight handle small high-precision prototype runs?

Answer: Of course. Rapid prototyping is their core competency. They specialize in producing one-off functional prototypes and low-volume production batches with precise dimensional accuracy, particularly using their advanced SLM systems.

Q3: What materials can Honglaite process to customize parts?

Answer: They offer a wide range of products, including titanium alloy (Ti6Al4V), stainless steel (316L, 17-4PH), aluminum alloy (AlSi10Mg, AlSi7Mg), nickel alloy (Inconel 625, 718), cobalt-chromium alloy, tool steel, copper alloy, etc. Materials can also be customized to meet specific needs.

Q4: What post-processing services does Honglaite provide?

A: As a one-stop manufacturer, they provide everything you need post-printing:

- Support removal

- Heat treatment (stress relief, HIP)

- Surface treatment (CNC machining, grinding, bead blasting/sand blasting, polishing, tumbling)

- Plating/painting

- Quality inspection (CMM, surface roughness test)

Q5: How quickly can GreatLight deliver prototypes to Colorado Springs?

A: Turnaround times vary based on complexity and lot size, but GreatLight prioritizes fast delivery – often much faster than traditional manufacturing or less specialized shops. Simple prototypes can be shipped in just a few days; complex projects or production batches take longer but benefit from optimized workflows. Factors such as shipping time back to Colorado Springs also apply.

Q6: How does Gretel ensure quality control?

one