Gothenburg: 3D printing innovation drives industrial development

Situated on the west coast of Sweden, Gothenburg is famous for more than just its canals and Volvo cars. It is quietly becoming the nerve center of transformative progress Metal 3D printingdriving new possibilities in aerospace, automotive and healthcare. Here, academic brilliance, industrial prowess and sustainability pioneers come together to redefine what additive manufacturing can achieve.

The Goldberg Effect: Innovation Ecosystem

The core of this revolution is Chalmers University of Technologya global leader in materials science research. Chalmers’ job High performance metal alloys – such as corrosion-resistant titanium alloys and thermally stable nickel superalloys – directly address aerospace durability challenges. Cooperate with giants such as Volvo and Saab Translate theory into practice. Volvo is using metal 3D printing to create lightweight, complex engine parts, while Saab is pushing the boundaries of defense applications with topology-optimized parts that cannot be manufactured traditionally.

Gothenburg takes the lead in breakthrough

- Multi-material and hybrid printing: Local startup is a pioneer printer that combines metals, such as steel-aluminum composites, in a single build. This enables functionally graded parts with variable properties, such as fusing heat-resistant edges to a lightweight core, which is critical for energy turbines.

- AI-driven process optimization: Gothenburg-based tech company integrates artificial intelligence with SLM (selective laser melting) machines. A real-time monitoring system predicts defects in prints and automatically calibrates laser parameters, reducing waste by up to 30% and improving repeatability.

- Sustainable metal additive manufacturing: Researchers are focusing on recycling high-value metal powders, such as titanium scrap, without losing quality, addressing the environmental footprint of additive manufacturing. The project funded by the Swedish Energy Agency aims to achieve a zero-waste metal additive manufacturing ecosystem by 2030.

Why industries trust Gothenburg-inspired solutions

In addition to R&D, Gothenburg fosters agile prototyping processes to speed up product development cycles. Its ecosystem masters the entire process: from computational design simulation to superior post-processing. This is where global players collaborate to tackle complex challenges such as:

- Prototype biocompatible implants with porous structures for better osseointegration.

- Manufacture conformal cooling injection molds for automotive plastics, reducing cooling time by 40%.

- Produce on-demand spare parts for marine engines, bypassing traditional supply chain delays.

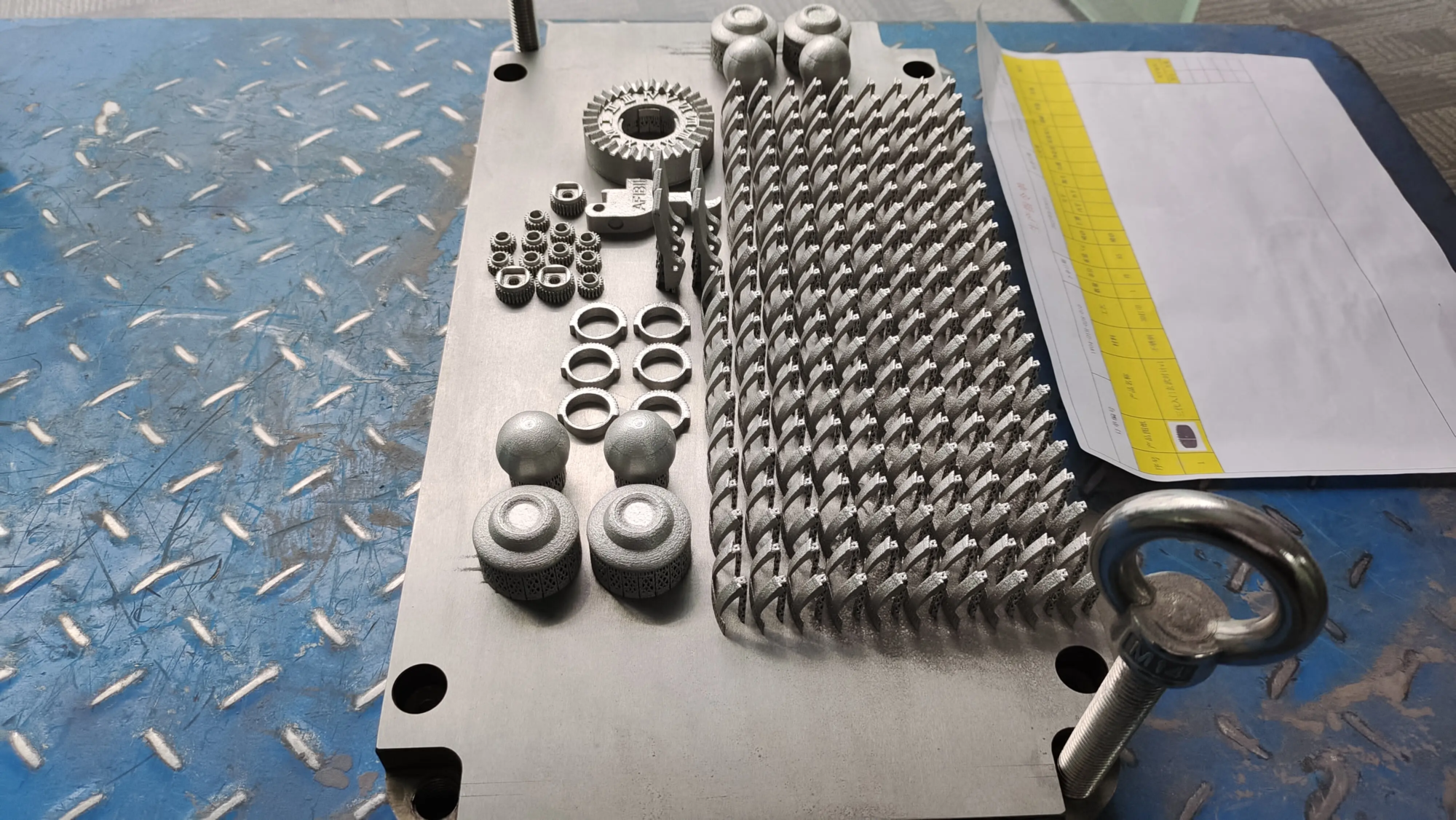

GreatLight: The gateway to Gothenburg-scale rapid prototyping

As Gothenburg pushes the technological frontier, companies around the world are looking for partners who can actually leverage these innovations. exist huge lightwe bridge this gap. As a leading rapid prototyping manufacturer, our factories integrate cutting-edge technologies SLM 3D printer and proprietary production technology. We solve complex metal part challenges quickly and accurately, providing:

- End-to-end metal solutions: From topology optimization design to heat treatment, surface polishing or EDM processing – everything is done under one roof.

- Material diversity: Machining stainless steel, aluminum, Inconel, titanium and custom alloys for special applications.

- Strict quality control: Laser scanning and CMM inspection ensure micron-level accuracy in compliance with ISO 2768 standards.

We help engineers in Europe and beyond iterate quickly and reduce product launch risk. Whether you are developing a fuel nozzle or a robotic surgical arm, our expertise turns groundbreaking concepts into functional metal reality. GreatLight provides prototyping to be production-ready.

in conclusion

Gothenburg exemplifies how regional cooperation can lead the transformation of global manufacturing. Its overall ecosystem blends academia, sustainability and industrial pragmatism to set the benchmark for metal 3D printing efficiency and innovation. For businesses, taking advantage of this change means partnering with forward-thinking suppliers. huge light Get ready to turn these advances into a competitive advantage: fast, accurate, and cost-effective metal prototyping to power your next breakthrough.

FAQ: Metal 3D Printing and Rapid Prototyping

Q1: What is the importance of Gothenburg for 3D printing?

A: Its dense network of R&D institutions (e.g. Chalmers University) and global manufacturers (e.g. Volvo, SKF) accelerate practical innovation, particularly in high-strength metal alloys, AI-enhanced printing and sustainable practices.

Q2: Which industries benefit the most from metal rapid prototyping?

Answer: Automotive (lightweight components), aerospace (heat-resistant turbine components), medical (custom implants) and energy (complex fluid handling systems). Prototyping allows for rapid iteration without expensive tooling or minimum order constraints.

Q3: Can Ferrite perform post-processing on metal parts?

Answer: Of course. We offer comprehensive post-processing services: stress relief, CNC machining of critical surfaces, polishing, powder coating or ultrasonic cleaning. Our one-stop approach ensures dimensional compliance and cosmetic excellence.

Q4: How do you ensure the materials are suitable for my project?

A: Our engineers review your performance requirements (e.g. thermal stability, corrosion resistance, fatigue strength) to recommend the best alloy – from aerospace-grade titanium to thermally conductive copper. Most materials are customizable.

Q5: What is your turnaround time for metal prototypes?

Answer: Typical SLM project delivery 3–7 working daysdepending on complexity and post-processing requirements. We speed things up without sacrificing quality – because getting things done quickly is at our core.

Q6: Why choose Huileite instead of competitors?

A: We combine German-designed SLM machines with strict quality protocols and proactive technical support. Our expertise ensures functional integrity – critical for the transition from prototype to production. Additionally, competitive pricing removes cost barriers.

Ready to take advantage of industrial-grade prototypes? Access the GreatLight platform now. Simply upload your CAD files to get instant quotes and design feedback for manufacturability. Quickly customize precision parts – innovation shouldn’t wait.