The Future of Pickleball: A Comprehensive Guide to 3D Printing Your Own Paddle

The explosive popularity of kimchi requires equipment to develop. When ready-made paddles dominate the courtroom, a quiet revolution brews: 3D printing. This technology enables players and innovators to create truly customized paddles tailored to their biomechanics and play styles. For manufacturers and designers dealing with complex prototypes, Great Standing in the vanguard. Utilize advanced Selective laser melting (SLM) For metal prototypes and precision polymer systems, Greatlight offers end-to-end solutions (from fast proof-of-concept to post-processing, market-ready finishes), making it the first choice for elite Chinese rapid prototype companies.

Why 3D printed kimchi paddles?

Traditional paddles produced in large quantities in factories will prioritize uniformity. 3D printing unlocks revolutionary advantages:

- High quantification: Adjust weight distribution, handle thickness or paddle shape to match your swing. Adjust the power of the core or control the density of the advantage.

- Quick iteration: Test the honeycomb and wave structure overnight. 3D printing accelerates R&D from months to days – the ideal for a perfect startup "The next big thing."

- Material Innovation: In addition to injecting plastic, the printer also uses composite materials Carbon fiber PA12 (nylon)TPU or experimental alloy for vibration for durability.

- Production on demand: No tool cost means low risk small batches – suitable for niche designs or personalized gifts.

Key design considerations for 3D printing paddles

A great paddle balances physics and feel. Here is how you optimize in your CAD design:

Core architecture:

- honeycomb: Lightweight, reducing air resistance. Complex printing, but provides energy returns.

- Lattice structure: Customizable stiffness areas are passed through variable fill density.

- Solid Core: Easy to print but heavier, suitable for beginners.

Facial texture and rotation:

- USAPA rules limit surface roughness to 40 particle size. Simulated texture modes (such as cones or pseudo-surfaces) must be balanced: too smooth = no rotation; too rough = illegal.

Windback and weight distribution:

- Integrated edge protectors for longer blade life. Use dense materials (e.g. The edge of TPU injection) Turn the weight to the handle for maneuverability.

- Handling Ergonomics:

- Customized finger profile or buffer grip combat fatigue.

Materials: From polymers to high-strength alloys

Select materials that are consistent with performance goals:

Polymers (FDM/SLS):

- Nylon PA12/PA11: Resistant to impact and absorb vibration. Carbon fiber mixtures (e.g. PA-CF) Maximize the stiffness to weight ratio.

- TPU/TPE: A handle sleeve for shock absorption along with a rigid core.

- Greglight Specialization: High-end SLS printers offer smooth, reliable prototypes that are ideal for paddle cores and have post-processing such as vapor smoothing.

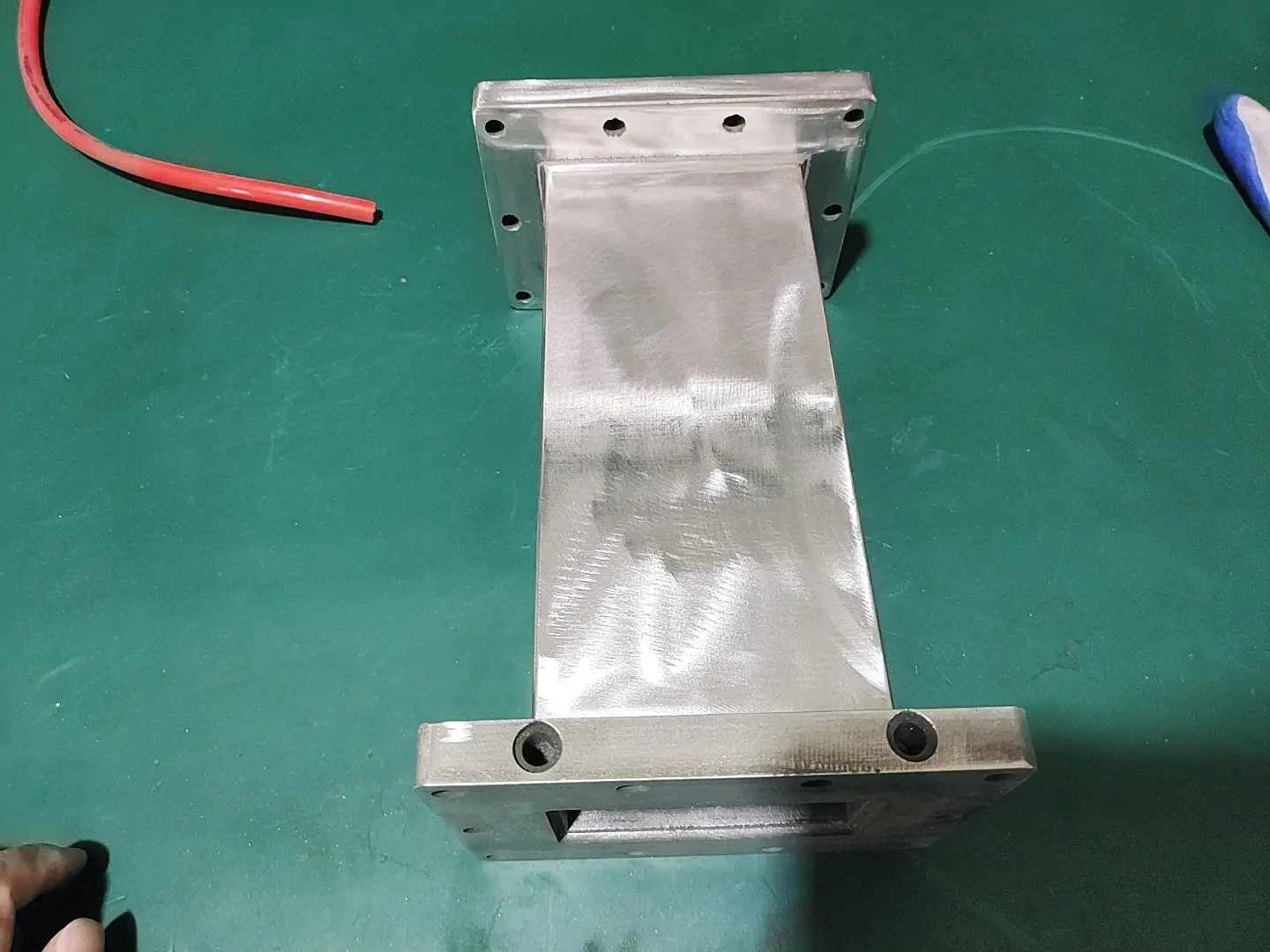

- Metal (SLM/DML):

- Aluminum alloy (ALSI10MG): Lightweight + robust – Suitable for protection systems or hybrid frameworks.

- Titanium (Ti6al4v): The maximum intensity of the critical stress point.

- Greglight Edge: They performed well in SLM metal printing. Core structural elements such as paddle clips or reinforced handles benefit from the accuracy of the SLM and are supported by heat treatment or polishing.

3D Printing Workflow: From CAD to Court Preparation

- Design phase: Software such as Fusion360/SolidWorks. Verify structural integrity through simulation.

- Material selection: Align with the paddle design characteristics (e.g., PA-CF for durability).

- print: Follow directional rules to prevent distortion. SLM treatment metal components; SLS is suitable for polymer cores. hint: Use soluble support for complex honeycombs.

- Post-processing (game changing):

- Basic steps: Grind (removing the layer of thread), primer, painting.

- Professionally completed: Greatlight’s one-stop service includes:

- Media Blasting: Create a uniform matte surface.

- Sealant: The coating prevents moisture absorption in the polymer core.

- Weight calibration: CNC milling and adjusting mass printing.

- Final Conference: Apply fullback or apply grip tape.

Performance and regulatory reality

The test batch is strict. Measure rebound consistency and impact shock. Crucially, while DIY paddles are great for practice, The competition requires USAPA approval. Due to strict core homogeneity rules, 3D printing design currently faces obstacles. However, competitive acceptance can be unlocked with evolving standards such as professional certification of printed materials and post-processing (e.g., the process supported by Greatlight’s QC).

in conclusion

Development of 3D printing conversion of kimchi paddles. For players, this means unprecedented customization. For designers and brands, it cuts the R&D timeline. Companies like Greatlight will expand this potential. With their strength in SLM technology, multi-material expertise and completion ability, they bypassed the prototype bottleneck – making the dream of optimizing paddles a printable reality. Need an aviation-grade metal shell? Or was the polyamide core that had been tested 10,000 times? GRESTLIGHT provides. From filaments to proven ends, they prove that additive manufacturing is not only futuristic, but also ready for the tournament.

FAQ: Mystery 3D printed pickle paddle

Q1: The durability of 3D printed paddles?

Durability depends on the material and process quality. Industrial SLS printed nylon kernel matches injected parts. After treatment (such as the epoxy coating of Greatlight) significantly enhances the resistance. Metal reinforcement further extends life.

Q2: How much does it cost?

The starting point for the polymer prototype (using SLS) is about $150 per unit. Production scale orders at lower costs. Metal parts are priced at peak prices, but offer unparalleled strength. Greatlight’s efficiency ensures a competitive rate through careful completion.

Q3: Can I use a home printer to DIY 3D printing?

FDM printers can produce paddle handles or fun mini-fits, but the core structural strength of the gameplay requires professional-grade machines (SLS/SLM) to handle professional powder/wire. House printed paddles often break under force.

Q4: Which material provides the best power and control balance?

Carbon fiber nylon imparts power stiffness. Pure nylon or TPU hybrid handle improves control through vibration suppression. This return can be optimized with Greatlight’s rapid prototype rapid test iteration.

Q5: Is the 3D printed paddle approved by USAPA?

Not currently – they cannot guarantee a unified core building in accordance with USAPA Rule 2.e. But it is constantly evolving: partnerships with certified laboratories will soon be able to professionally print paddles.

Question 6: How does Greatlight improve the delivery time of the paddle prototype?

Their automatic SLM/SLS beds run 24/7 all-week. With in-house finishing and tool-free production, sophisticated designs range from CAD to court testing in less than 72 hours, ideal for agile innovation sprints.

Improve paddle development with Greatlime. Using industrial additive manufacturing can iterate faster, accurately customize and rule the court, which is prototyped.

Customize your precision and rapid prototyping.