The world of 3D printing has revolutionized all industries including security and introduced 3D printing locks. These innovative locks have attracted attention in recent years due to their unique features, benefits and potential to undermine traditional locking systems. In this article, we will dig into the world of 3D printed locks and explore their characteristics, advantages and applications.

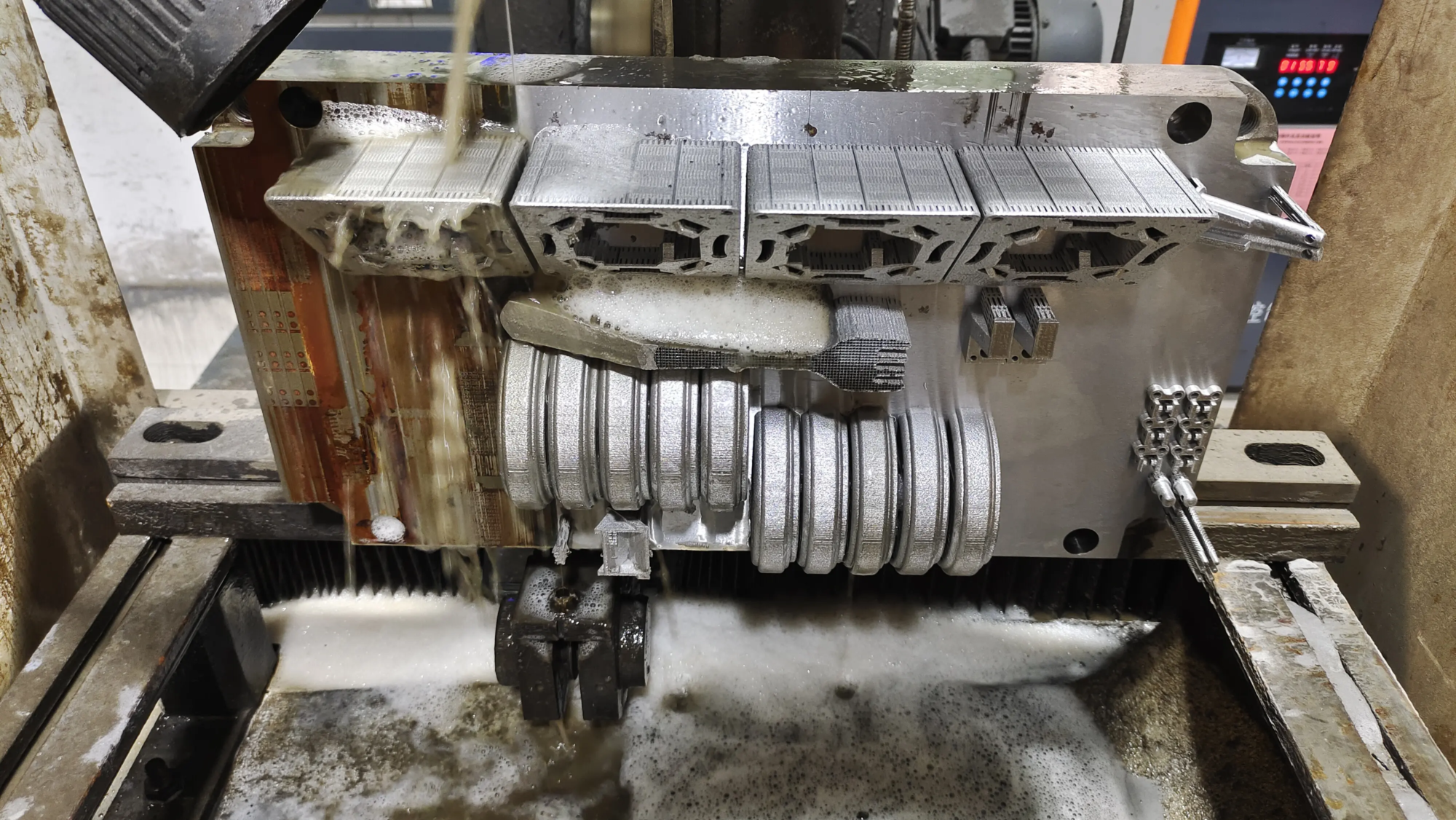

One of the main advantages of 3D printed locks is their customizability. By using advanced 3D printing techniques such as selective laser melting (SLM), the complex geometry and structures produced by traditional manufacturing methods can be designed and manufactured. This allows the creation of locks with unique keyways, shapes and sizes, making them highly resistant to unauthorized access.

Another important benefit of 3D printed locks is their potential to improve safety. Traditional locks usually rely on mass-produced components, which are vulnerable to exploitation by attackers. In contrast, 3D printed locks can be designed using complex internal mechanisms and security features, making them harder to pick or break. Additionally, the use of advanced materials such as metal powders can enhance the strength and durability of the locks, making them more resistant to forced entry.

The applications of 3D printing locks are diversified and diversified. They can be used in a range of industries, including aerospace, automotive and healthcare, requiring high-security locking systems. Additionally, 3D printed locks can be used in consumer products such as safes, cabinets and door locks, providing additional security and protective layers.

Greglight is a professional rapid prototyping manufacturer, the forefront of 3D printing technology, providing advanced SLM 3D printers and production capabilities. With the ability to produce complex metal parts quickly and efficiently, Greatlight has a great location to meet the growing demand for custom 3D printed locks. Their expertise in post-processing and completion services ensures the highest quality of the final product and meets strict standards in the safety industry.

In short, 3D printed locks represent significant innovations in the security field, providing enhanced customizability, security and durability. By using advanced 3D printing technologies and materials, these locks have the potential to disrupt traditional locking systems and provide unparalleled protection for a variety of industries and applications. As technology continues to evolve, we can expect to see further innovations and applications of 3D printed locks, which will revolutionize our view on safety and protection.

FAQ:

Q: What is 3D printing and how to create locks?

A: 3D printing is a manufacturing process that creates objects through materials such as metal and plastic based on digital designs, such as metal and plastic. This technology is used to create locks with complex geometry and internal mechanisms that cannot be generated using traditional methods.

Q: What are the benefits of 3D printing locks?

A: The benefits of 3D printed locks include customizability, safety and durability. They can be designed with unique keyways, shapes and sizes, making them highly resistant to unauthorized access.

Q: What material is used to create 3D printed locks?

A: Advanced materials (such as metal powders) are used to create 3D printed locks, which enhance their strength and durability.

Q: Which industries can benefit from 3D printed locks?

A: Various industries including aerospace, automotive, healthcare and consumer products can benefit from 3D printed locks that require high-security locking systems.

Q: How to get a custom 3D printing lock?

A: Companies like professional rapid prototyping maker Greatlight offer custom 3D printing services that allow you to design and manufacture unique locks that meet your specific needs and requirements.

ISO 9001 Factory