3D Printed Luffy: Bring the Straw Hat Captain to Life with Custom Collectibles

The world of collectibles has been revolutionized thanks to 3D printing technology. Perfect for fans of iconic anime and manga series one piece the dream of having a unique and personalized Monkey D. Luffy figure can now come true. Unlike mass-produced figures, the 3 Tohoku 3D printed versions offer unparalleled customization – whether capturing Luffy’s mid-range 5 transformation, replicating Arlong Park’s battle scars, or designing original poses. As demand grows, hobbyists and creators turn to advanced prototyping partners such as huge light Guide the complex journey from digital design to masterpiece worthy of display.

Why 3D print a Luffy model?

Mass-produced anime characters, while visually appealing, lack uniqueness. They are limited to predefined poses, expressions and accessories. Via 3D printing:

- true customization:Create dynamic poses, personalized facial expressions or alternative outfits (e.g. Wano outfits).

- scale flexibility: Print a miniature for your desk or 20-inch centerpiece.

- creative ownership: Get rid of licensing restrictions. Design hybrid concepts, e.g. "Cyberpunk Luffy" or "Samurai Luffy."

- Cost effective: Low-volume prototyping costs less than traditional injection molding.

How It Works: From Sketch to Straw Hat Pirates

Step 1: Digital Modeling

Start with an accurate digital model. Use sculpting software like ZBrush or Blender, or optimize existing STL files from platforms like Thingiverse. Pro Tip: Ensure mesh integrity with waterproof geometry to avoid print defects.

Step Two: Material and Technology Selection

Your choice depends on aesthetics, durability and budget:

- Resin (SLA/DLP): Great for hyper-realistic details (e.g. facial features, gum fruit textures). Beautiful; best for display.

- PLA/PETG (FDM): Durable and affordable, but lacks the finesse of resin.

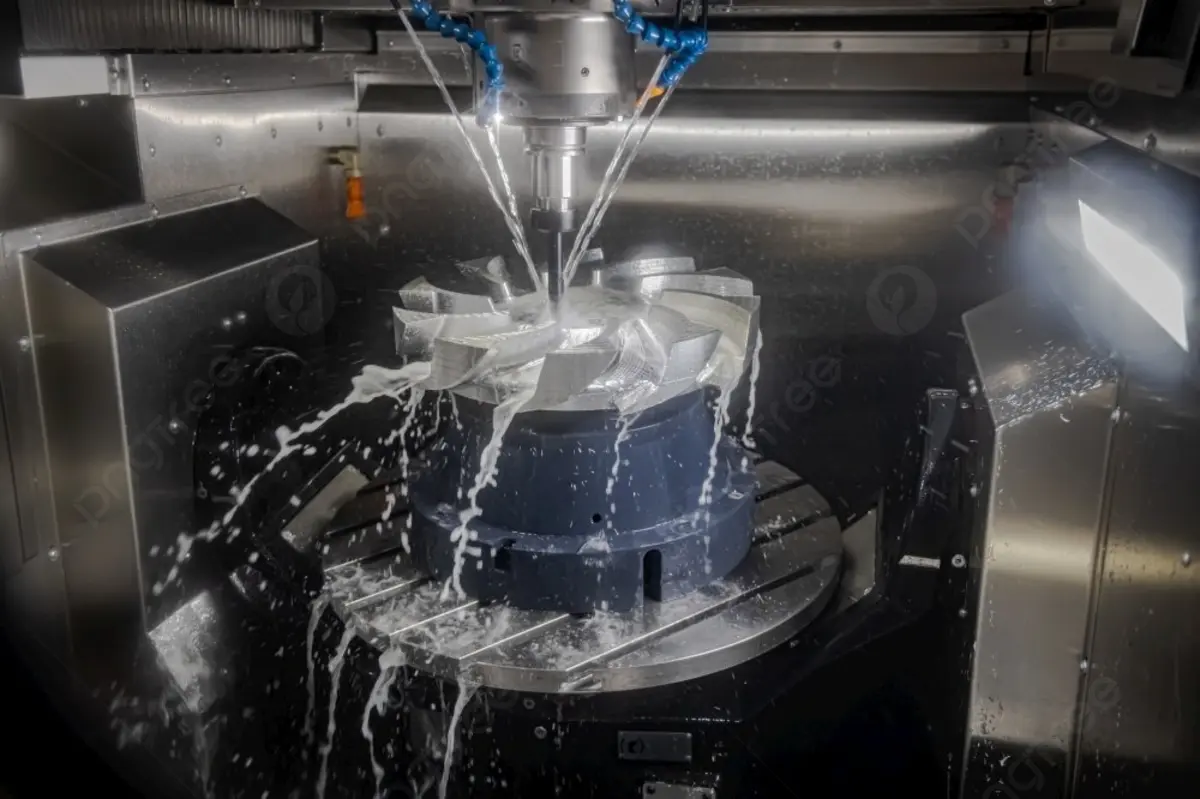

- Metal (SLM): For premium metal finishes. company likes huge light Specialize in SLM printers that transform stainless steel, titanium or aluminum into durable works of art. Metal is great for accessories like Luffy’s hat or base.

Step 3: Post-Processing – Where the Magic Happens

The original print requires refinement:

- SupportSuppor support removal: Carefully dismantle the scaffolding structure.

- Sanding/Polishing: Smooth layer lines on plastic; polishes metal to a mirror shine.

- painting:Hand-paint with acrylics or use an airbrush to paint the gradient. Seal with matt/gloss varnish.

- assembly: Attach multi-part prints (e.g. detachable arms for pose variations).

Work with a full-service professional such as huge light Simplify this stage. They handle it all: precision machined returns, electroplated metal effects or sandblasting for a uniform matte texture.

Overcome common challenges with professional partners

Print enthusiasts often face obstacles:

- loss of detail: Complex Gear 5 features or flowing cape textures require an industrial-grade printer. huge lightOur high-resolution SLA/SLM machines perfectly capture details down to 0.05 mm.

- structural weakness: Thin elements (such as Luffy’s outstretched arm) may not be FDM printable. Metal SLM or composite-infused resin ensures rigidity.

- Cosmetic defects: Layer lines, bubbles or distortions destroy realism. Professional post-processing eliminates these.

- Material limitations: Standard plastic looks cheaper than die-cast metal. GreatLight’s custom metal alloys add weight and authenticity.

Why Choose Professional Rapid Prototyping Services?

While DIY printing is valuable, outsourcing it to experts like huge light Offers advantages:

…………………

- speed: Get parts in days instead of weeks with automated production lines.

- accurate: Achieve dimensional accuracy within ±0.1 mm using calibrated industrial printers.

- Material range:Use engineering grade nylon, flexible TPU or unused corrosion resistant metal for consumer machines.

- One-stop organization: From heat treatment to powder coating – all under one roof.

As a leader in rapid prototyping manufacturing in China, GreatLight combines cost efficiency with cutting-edge SLM 3D printing capabilities to solve the complex metal part challenges that plague hobbyists. Their expertise ensures your Luffy character is well constructed, visually stunning, and truly unique.

in conclusion

3D printing unlocks unlimited potential one piece Fans immortalized their favorite pirate captain in physical form. Whether you want a battle-ready Luffy frozen in jet pistol action or a metal rendition fit for a treasure trove, the fusion of digital design and advanced manufacturing allows for unparalleled creativity. For projects requiring complex geometries, high-quality materials or exhibition-grade finishes, work with experienced partners such as huge light Transform ambitious visions into tangible realities. They bridge the gap between fan art and professional collectibles, ensuring every Straw Hat badge, scar and smile is represented with cinematic fidelity.

Are you ready to start your custom Luffy adventure? Embrace excellence in prototyping.

Frequently Asked Questions (FAQ)

Q1: Is it legal to 3D print a Luffy figure for personal use?

A: Yes, creating unlicensed characters for personal display falls under "fan art" and is generally allowed. promiseHowever, selling copyrighted designs violates intellectual property laws.resonance resonance

Q2: How much does it cost to print a 12-inch Luffy figure?

A: Resin prints start at about $50 for a basic model. Professionally machined metal or multi-material partshuge light May range from $200 to over $600, depending on complexity and enhancements such as painting or metallization.

Q3: How long does metal 3D printing take?

A: For a normal statue, SLM printing takes 24-48 hours. Including design, post-processing and quality inspection, turnaround time from a professional company like GreatLight is typically 5-10 days.

Q4: Can I use my own 3D model?

Answer: Of course. Provide your STL/OBJ files and the prototyping service will optimize them for printing. Many also offer modeling assistance to refine details or ensure structural integrity.

Q5: Why choose metal instead of resin or plastic?

Answer: Metal (e.g.,