Make legendary artifacts: A guide to 3D printed Majora masks with industrial precision

For fans The Legend of ZeldaMary’s mask is more than just a game souvenir, it is an iconic symbol of mystery and craftsmanship. Recreating such complex artifacts requires precision, creativity and advanced manufacturing technology. As a professional rapid prototype manufacturer, Great Lever tip SLM (Selective Laser Melting) 3D Printing Technology and comprehensive collation services transform your vision into a tangible masterpiece. This guide explores the journey from digital models to completing masks, showing how industrial-grade 3D printing can solve complex manufacturing challenges.

Why 3D printing is great for Majora’s masks

Majora’s masks have organic curves, intricate prints and asymmetrical details that go against traditional manufacturing. CNC machining or hand-engraved with:

- Complex geometric shapes: Undercut, hollow parts and fine surface texture.

- Substance restrictions: Durability is required to display or role-play.

- Time/cost efficiency: Small volume production without custom tools.

Especially 3D printing Metal SLMconquered these obstacles. Layer-by-layer manufacturing perfectly constructs the alien aesthetic of the mask while achieving custom size, material selection and structural integrity.

Step by step: From model to masterpiece

1. Digital design improvements

- Source 3D models (e.g. from CAD software like game tear or Blender).

- Optimized printability: Ensure wall thickness ≥1mm, strengthen stress point and direction support to minimize post-processing.

- Greglight’s expertise: Our engineers optimize design manufacturability to avoid warping or failed printing.

2. Material selection

- Stainless steel 316L: Ideal for durability and metal finish.

- Titanium (Ti6al4v): Lightweight but robust, perfect for role-playing.

- Copper or bronze:For antique aesthetics, compatible with patina finish.

- GRESTILLE ADVATICE: Extensive material customization (even exotic alloys) and with fast-changing procurement.

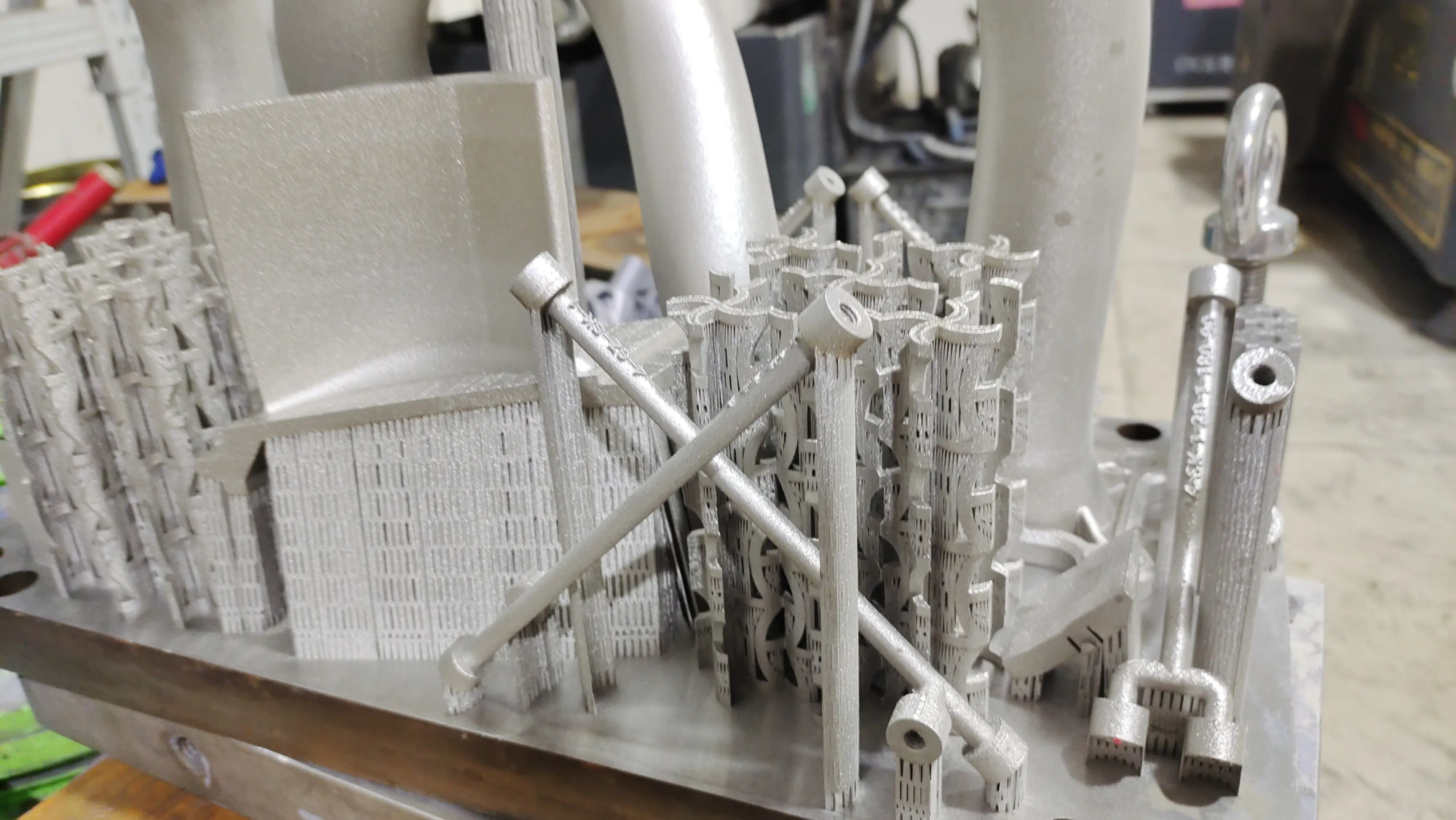

3. SLM 3D printing process

Our industrial SLM printers fuse metal powder with high power lasers to form a completely dense layer (as thin as 20μm). Benefits include:

- accurate: ±0.1mm precision captures all engravings.

- strength: No weak joints; overall building.

- speed: 48–72 hours of printing cycle with several weeks of traditional methods.

4. Excellent post-processing

The original print needs improvements to achieve the legendary effect of the mask:

- Support deletion: CNC assisted cutting for complex geometric shapes.

- Surface polishing: Rolling, bead blasting or hand-dividing.

- detail: Chemical etching to enhance texture.

- Finish: Electroplating (gold/silver), powder coating or antique filling.

- One-stop solution: Greatlight handles all post-processing internally to ensure seamless quality control.

Pushing the Boundaries: Advanced Applications

- Functional Role Playing: Integrate LED eyes or modular parts with the accuracy of SLM to interchange expressions.

- Art installation: Expand to wall-mounted displays with aluminum alloy to reduce weight.

- Collector’s version: Combining 3D printing with lost wax casting to achieve limited bronze replicas.

Why collaborate with Greatlight?

As one of China’s fastest prototype companies, we address challenges other providers cannot:

- Fast Market: 5-7-day production for most metal projects.

- End-to-end control: Design support, material procurement, printing and finished under one roof.

- Accurate certificate: SLM technology ensures aviation-grade tolerance (<0.1mm).

- Cost-efficiency: Customized one-time or batch (1-100+ units) competitive prices.

Elevate your project with industrial rigor – the demanding design of the mask doesn’t match the technology of Greatlight.

in conclusion

3D-printed Majora’s masks blend fanatics with engineering innovation. By leveraging SLM technology and overall finishes, Greatlight turns digital dreams into heirloom quality artifacts. Whether used for role-playing, art or collectibles, our expertise ensures unparalleled incomparable to the weird grandeur of the original. Embrace additive manufacturing to create what was once considered impossible – incorporate the legend of Hyrule into reality.

FAQ: 3D Print Majora’s Mask

Q1: Can I print Majora’s mask in plastic instead of metal?

Yes, but metals (especially stainless steel or titanium) offer high durability and finish. For lightweight needs, we offer engineered resin or nylon composites.

Q2: How much does it cost?

Palm-sized stainless steel mask (6-8 cm) costs $200. Factors include dimensions, materials, and finish complexity. Request a free quote using 3D files.

Q3: What if my model is not printed?

Our engineers will optimize your design at no extra cost – maintain structural integrity while preserving details.

Q4: Is the painted finish durable?

Yes! Our powder coatings and electrochemical finishes resist chipping. For metal mass, seamlessly seam the bonds with the base material.

Q5: How long does it take to produce?

SLM printing takes 2-3 days; post-processing increases by 3-5 days. Urgent services are available.

Question 6: Can I expand my mask to life size?

Absolutely. SLM handles large builds (up to 300x300x350mm), and components can seamlessly combine multiple printed parts.

Q7: Are you shipping globally?

Yes, it contains tracked logistics and customs documents.

Q8: Which file format do you accept?

stl, obj, step or 3mf. For complex designs, the compressed (ZIP) folder is preferred.

Unleash your creativity –Customize Majora mask now With Greatlight’s primary rapid prototyping service! If you have any questions or ideas to share, feel free to comment and follow our newsletter for more innovative projects.