Forged Evil’s Bane’s Blade: Making the Perfect 3D Printing Master Sword

The legend of Zelda’s main sword is more than just a weapon. This is an icon. Can be recognized immediately with a winged guard, royal blue grip and glowing blade, which represents a victory over courage, strength and light beyond the darkness. It is a precious dream for role-players, collectors and gamers to have a faithful body replica. Although traditional materials such as wood or metal pose significant challenges in terms of skill, time and cost, modern 3D printing technology provides a revolutionary path to wielding Hyrule’s most sacred blades.

Why 3D printing rule the main sword supreme

Recreate the complex details of the main sword – subtle runes on the blade, complex curves on the guard, complex patterns on the hilt – a manual tool alone cannot be precise. 3D printing is excellent here:

- Digital Accuracy: Starting with high-quality 3D models (widely used in the enthusiast community or custom renderings), every nuance is captured digitally, ensuring perfect symmetry and loyalty to the source.

- Complexity is free: Unlike subtraction manufacturing, 3D printing effortlessly deals with complex internal structures, overhangs (critical to the defender’s wings), and complex surface details without significantly increasing costs.

- Material versatility: Depending on the final appearance required, different materials can be used. Plastic is perfect for lightweight role-playing, and Metal Unlock unrivaled authenticity and durability.

- Scalability: From displaying miniature to full-size hero props, easily adjust the size to suit your needs.

Challenge: Beyond Simple Plastic Prototypes

Desktop FDM printers can be produced form On the main sword in PLA or ABS, achieving a truly premium, durable and worthy of display replicas usually requires more:

- Durability: Plastic swords lack rigidity and are prone to bends or bends, especially blades. This is crucial for something to be held high.

- Weight and Feeling: Plastic feels like a toy. The main sword should have a satisfactory weight similar to its source.

- Surface quality: Layer lines require a lot of post-processing to achieve smooth, upcoming surfaces that are critical to mirror-like blades or complex details.

- Details: Using low-resolution printing methods, highly complex details on guards or handles may be lost.

This is where professional metal 3D printing, especially selective laser melting (SLM), can change the game.

Input Metal: SLM – Future Forging

Selective laser melting (SLM) is a major metal additive manufacturing technology that provides the ideal solution for making a truly legendary master sword:

-

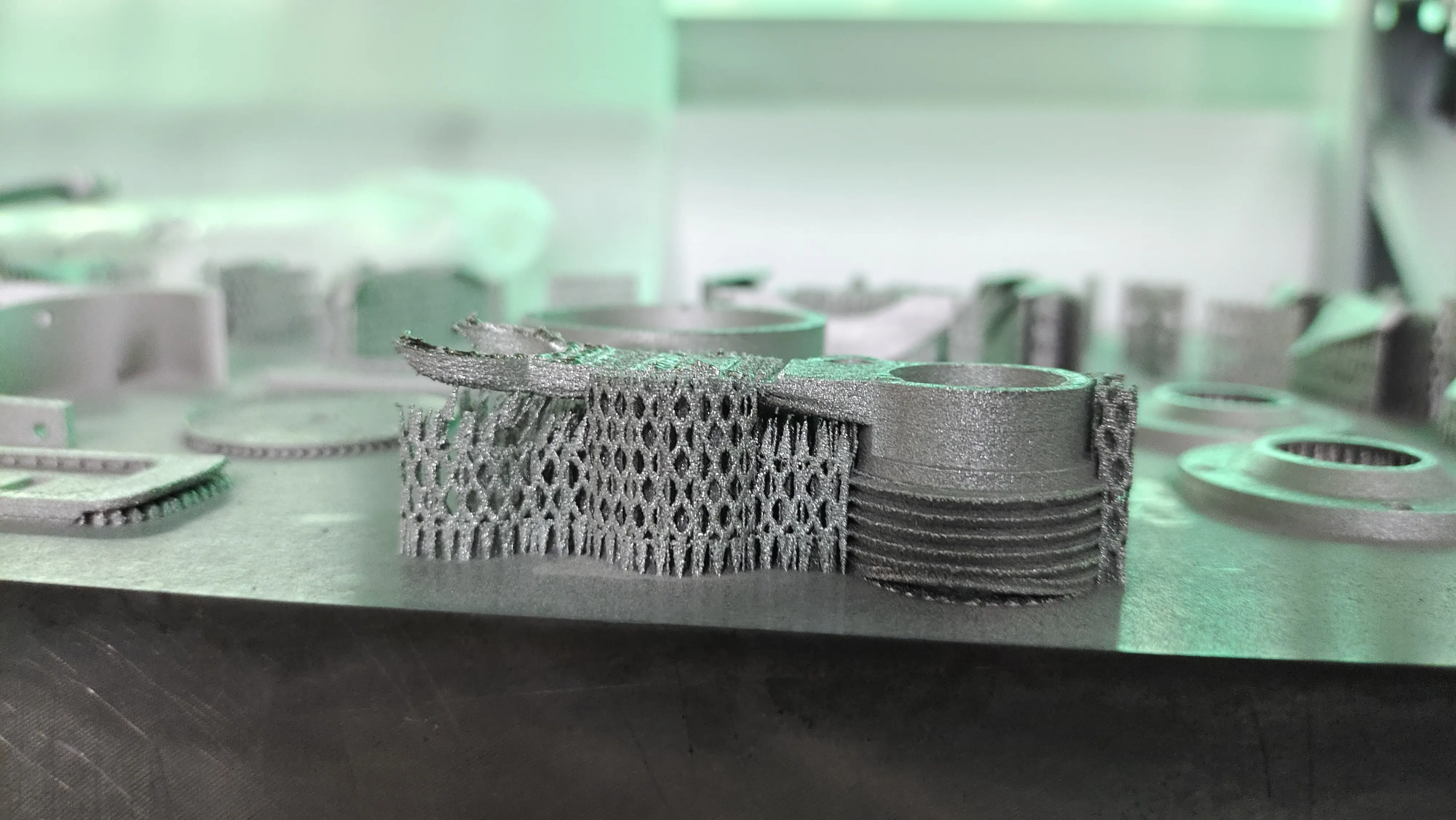

Digital Crucible: The 3D model you choose is actually cut into ultra-thin layers. key? Model optimization By experienced engineers. Support is strategically designed to enable complex geometric shapes such as guard overhangs, while minimizing inevitable artifacts. Wall thickness is analyzed to ensure printability without warpage.

-

Melt metal, melt one layer: A fine bed of metal powder (such as the final exhibition of stainless steel 316L, aluminum alloy and even titanium) is placed accurately. A high-power laser beam fuses the powder particles together and tracks the precise cross-section of the layer with precise accuracy and adheres to the underlying layer. This will be repeated carefully until the entire sword forms inside the powder bed.

- Advantages of Metal SLM:

- Unrivaled strength and durability: Metal prints are rigid and sturdy in nature. Your sword will not bend or break under its own weight or manipulation.

- Outstanding details: SLM achieves incredibly high resolution, accurately recreating the smallest runes and decorative boom.

- Real weight: Metal provides the satisfactory weight expected by the legendary blade.

- Completed Senior Foundation: A well-printed metal surface provides an excellent foundation for polishing, gold plating or plates.

The Art of Post-processing: From Original to Masterpiece

The powder bed appeared with original SLM prints, an incredible feat of engineering, but required a skilled finish to become a seal. Here, full-service providers become priceless:

- Careful support for deletion: Professionals can safely remove complex support structures without compromising delicate features.

- Surface Improvements: Processing begins, including:

- Shooting/Sanding: For initial surface smoothing and texture refinement.

- CNC machining (key): To achieve the perfect flatness of the iconic blade, the mirror-functioning surface is crucial. This is where precision machining capabilities are crucial.

- Hand polishing and polishing: The gradually thinned abrasive removes the tool markings and layer lines, achieving the desired surface quality on all components.

- electricity: (Optional) Used for uniform and smooth micro finishes on metals such as stainless steel.

- Completed by hand:

- Painting and coating: The meticulous masking and spray gun reproduces blue and purple grips, the accent of the golden guard and any blade weathering effect. Heat treatment can induce oxide colors on titanium, such as gold and blue.

- assembly: For seamless end products, precise fit and bond or fixation of components (blades, guards, grips, pommels).

- Final touch: Clear the jacket for protection, apply symbolic decals, and even embed artificial gemstones.

Why collaborate with your sacred replica?

Forging the main sword through SLM requires professional equipment, deep materials expertise, and unparalleled printing and completion skills. Greglight is ready to be your ally in this quest:

- Industrial SLM Powerhouse: We leverage cutting-edge SLM metal 3D printers that are able to handle the large build volumes required for full-size props and complex details.

- Material Master: Custom made with strength, detail and beauty of a variety of certified metal powders (stainless steel, aluminum, titanium).

- End-to-end excellence: A true one-stop service. From initial model optimization and printability checks to expert post-processing, including critical CNC machining of blade precision and hand-finished finishes, Greatlight handles all operations under one roof. There are no multiple suppliers.

- Quick and accurate prototype DNA: Our core expertise is to transform complex digital vision into high-fidelity physical reality. We understand deadlines and quality requirements.

- Core customization: In addition to copying known designs, we can also modify scales, material selection, completion types, and even integrate unique personal styles.

Conclusion: Make your legend true

The dream of holding the main sword no longer requires magic or the life of a blacksmith. Advanced metal 3D printing (particularly SLM) combined with expert post-processing can unlock the ability to create replicas of accuracy, durability and presence. This journey from digital design to artifacts requires not only technology, but also deep technical knowledge and smart craftsmanship.

By working with professional rapid prototyping experts like Greatlight, equipped with the right technology and comprehensive finishing capabilities, you can go beyond the limitations of standard prints. You can access the tools and expertise needed to forge the main sword worthy of display or action – this is the real Hyrule. Unleash your courage; explore how Precision 3D printing brings legendary characters into your world.

Frequently Asked Questions about the 3D Printed Master Sword (FAQ)

1. Can I really buy a 3D printed main sword of metal?

Absolutely! Using Industrial Selective Laser Melting (SLM) technology, companies like Greatlight can professionally print your main sword replica using powerful and durable metal alloys such as stainless steel, aluminum or titanium. In every way, it is much better than plastic.

2. How durability is a metal 3D printed sword compared to plastic?

The league ahead. Metal prints, especially those from SLM, are fundamentally solid and rigid. The high-quality metal main sword replica is powerful enough to display, carefully handle and role-play (weight allowed). Plastic prints (FDM/resin) are accurate but more fragile, with blades prone to rupture and lack overall rigidity.

3. Will the sword be completely finished and look like a game?

It depends on the provider. Find a full-service partner that provides comprehensive post-processing. On Greatlight, we include critical post-processing steps such as CNC machining blades for original flat, professional hand-polishing and polishing, high-quality painting (matching the iconic blue grip, gold guard) and assembly, as part of our metal printing products. The playback completion that can be achieved is possible.

4. Which material is best for display? Cost and authenticity?

- Stainless Steel (316L): The most popular choice for metal replicas. Excellent durability, weight, surface thunderability and cost-effectiveness. Can be polished mirrored or painted/coated.

- Aluminum alloy: Lighter than steel, but still very durable. Perfect for details and finishing. The paint is good. Large chunks or weight are ideal for a problem.

- titanium: Provides the ultimate quality look. Naturally strong. Can be anodized to produce stunning blue, purple and gold – perfect for Master Sword accent without paint. Higher cost, but unparalleled uniqueness. Resin or plastics can only remain budget-friendly if the weight/durability of the metal is not a priority.

5. How much does it cost to make a professionally made metal 3D printed main sword?

Costs are based on size (full size models are larger than many people realize!), material choice (titanium is advanced), requested complexity and level (basic sanding with full mirror polish + painting + components) and ultimate complexity (support structure) (support structure). While metal replicas are more expensive than desktop plastic prints, it is an investment in durable, high-quality craftsmanship. Contact Greglight for specific detailed quotes tailored to your horizon.

6. Can Greatlight modify the design? What if I have my own 3D model?

Yes, yes! We welcome custom projects. We can adjust the size of known designs. More importantly, Gremight excels in custom precision machining. Whether you provide us with existing .STL files online procurement or have your own unique concept, our engineering team can optimize SLM printing, perform printability checks, and guide you in adopting materials and completing choices to bring your vision to life.

Step into your pursuit of waving this legendary symbol. Contact Greatlight now to discuss your own masterpiece of 3D printing masterpieces of swords!