Unleash your inner mouser: A comprehensive DIY guide to 3D printing mouse ears

Remember the iconic silhouette of playful mouse ears? They’re more than just theme park souvenirs, they’re symbols of joy, whimsy and personalized fandom. If you could make your own A unique pair? Enter the amazing world of 3D printing! This guide enables you to design, print, and assemble custom mouse ears, turning your digital dreams into a wearable reality. Forget generic designs; imagine ears shaped like the Milky Way, decorated with your favorite animals, or sparkling metallic elegance. Let’s start your DIY journey!

Why go the DIY 3D printing route?

- Unparalleled customization: Get rid of mass-produced designs. Create ears inspired by anything: zodiac signs, sports teams, abstract patterns, beloved characters (original designs) or seasonal themes. Your imagination is the only limit.

- Cost-effective fun: Printing your own ears is much cheaper than buying high-end branded versions, especially for complex or multiple designs.

- Empowering creation: It’s so rewarding to wear something you designed and made yourself.

- PERFECT FIT AND COMFORT: The base is designed to contour to your headband for comfort and ensure stability.

Step-by-step guide to creating your signature ears

-

Conceptualization and design:

- inspiration: Draw your ideas! Think shapes, themes, and colors. Simple geometric shapes (circles, ovals, stars) are easier for beginners, but complex designs can also be achieved with practice.

- Software proficiency:

- Beginner friendly: Tinkercad (free, web-based). Great for combining basic shapes, creating cutouts, and adding simple textures.

- Intermediate/Advanced: Fusion 360 (free for enthusiasts) or Blender (free). Provides greater accuracy for organic curves, intricate details, and parametric modeling. Consider designing the ear shape itself and a separate, sturdy mounting clip base.

- Key design considerations:

- Dimensions and scale: Typical ear surface diameter is 3-4 inches. Consider weight distribution.

- Attachment system: Design a sturdy clip, slot or loop that securely attaches to a standard headband. Make sure the contact area distributes the force to prevent breakage. Sloped base improves fit.

- Wall thickness: Aim for a minimum of 1.5-2.5 mm to ensure structural integrity. Avoid very thin parts that can break easily.

- Details and holes: Make sure fine details (like small text or holes) are large/sturdy enough to print reliably.

-

Materials matter – choose your filament/medium:

- Standard plastic wire:

- People’s Liberation Army: Easiest to print, wide color range, biodegradable (industrial). Great for beginners and decorative ears. Less flexible – avoid very thin designs.

- Polyethylene glycol: More durable, impact-resistant, flexible and slightly temperature-resistant than PLA. Excellent balance for wearable items. Better withstands bends in the headband.

- TPU/flexible filament: Ideal for ears that require extreme flexibility or bendable attachments. Printing fine shapes is challenging.

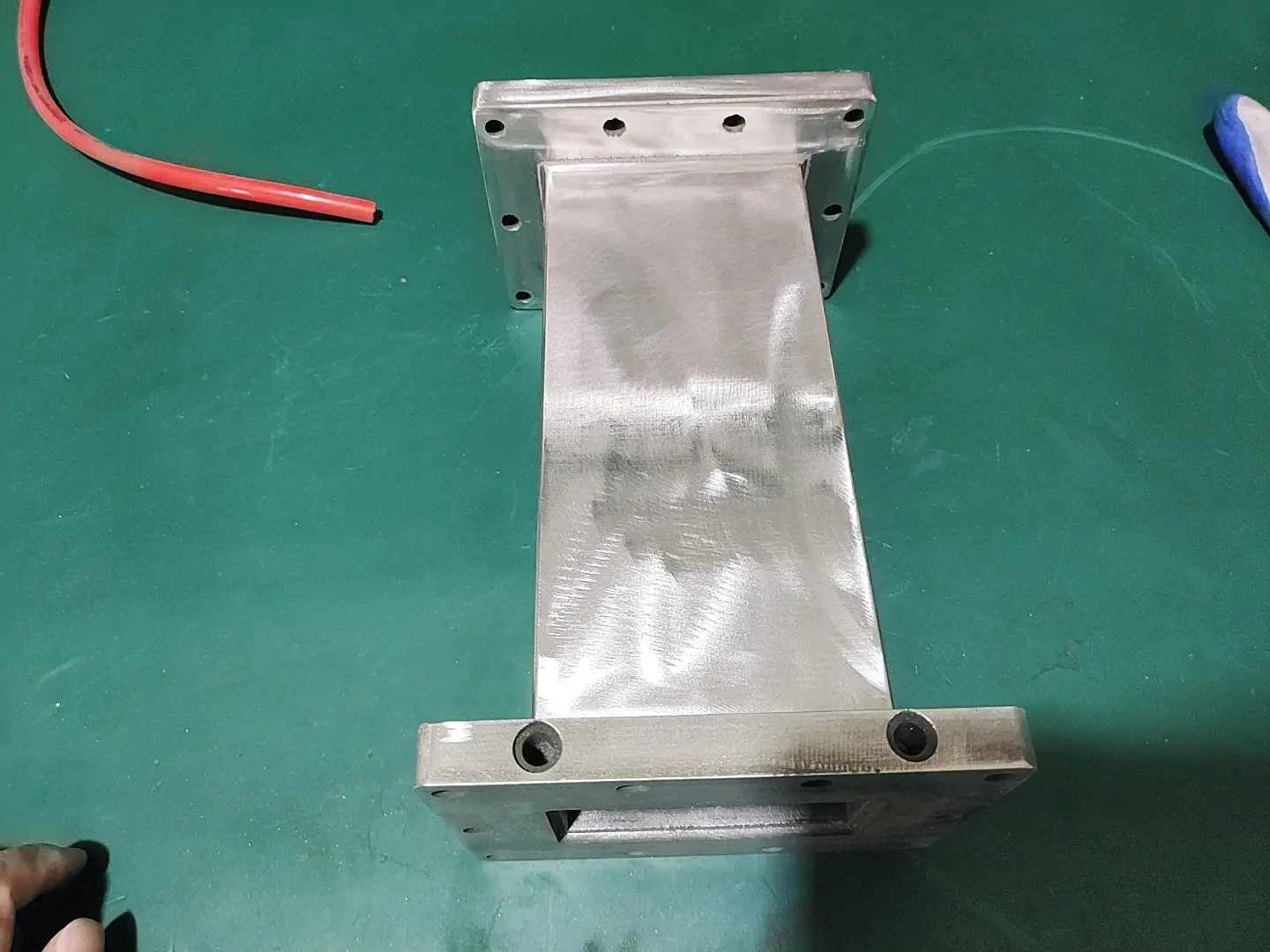

- Going pro and metal? : Dreaming of lightweight, polished aluminum or stylish titanium ears? This is where collaboration with huge light Sparkling. As the leader in rapid prototyping with advanced SLM (Selective Laser Melting) metal 3D printers, they can transform your complex digital designs into stunning, durable metal realities. Its one-stop post-processing (smoothing, polishing, powder coating) ensures a luxurious, skin-safe finish not possible with desktop FDM printers. Perfect for quality, jewel-like ears.

- Safety first: With plastic, be sure to sand the surface that contacts your skin smooth to avoid irritation. For metal parts from services like GreatLight, discuss biocompatible coatings if sensitive skin is a concern. Remove sharp points/edges.

- Standard plastic wire:

-

Print your ears: Convert bytes to bits

- Printer preparation: Carefully level your bed. Make sure the filament is dry.

- Support structure: Most designs, especially those with overhangs or complex bases, require supports. Use trees or organic supports (in slicers like PrusaSlicer, Cura, etc.) to minimize contact points and material waste/cleanup.

- direction:

- Flat: Print the ears face down for the best top surface quality. Support is required below any overhang/attachment points. Removal of supports may result in markings on the surface.

- upright: Print with the accessory base facing down. Minimize support within The ear design itself but needs support behind There is a protruding part on the ear surface. Post-processing (sanding/painting) is crucial for layering lines on the face.

- set up: Use recommended filament temperature settings. Moderate padding (20-30%) is enough. The goal is to achieve finer layer heights (0.15-0.2 mm) for a smoother surface that requires less sanding.

-

Post-processing and finishing magic: Transform rough prints into masterpieces

- Cleanup: Carefully remove the support structure using flat-head scissors, tweezers, and a needle file.

- Polishing: Start with coarse granularity (e.g. 120) and gradually move to finer granularity (up to 800+). Wet sanding reduces dust. Sand all surfaces smooth, especially attachment points and edges.

- Primer and Paint:

- Use a thick build primer spray (light coat) to hide layer lines. Sand again between coats for an ultra-smooth finish.

- Paint with acrylic paints. Use a stencil or a fine brush for details. Seal with clear matte/satin/gloss acrylic spray sealer for protection and UV resistance.

- Alternative finishes: Consider adhesive-backed glitter, vinyl graphic coverings, or removable coverings (like felt/fabric).

- Professional metal surface treatment: if huge light Use their expertise to build your metal ears. They can handle complex post-processing such as professional CNC machining for a perfect fit, smooth/vibrated finishing for an incredible tactile feel, precision polishing (mirror or brushed finishing), and even durable color coatings such as PVD (Physical Vapor Deposition) plating. Their finishing transforms raw printed metal into eye-catching jewelry.

- Assembly and decoration: Putting it all together

- scarf: Use a comfortable, fabric-covered plastic headband. The metal band can be bent to achieve the perfect head contour.

- Attachment mechanism:

- Clip/snap design: Make sure the printed clip is sturdy and sized for the thickness of the headband.

- glue: Strong epoxy or cyanoacrylate (superglue) is best for plastic to plastic bonding. Make sure the surface is clean and rough for the glue to be applied.

- Sewing/Fabric: Create the base of the fabric sleeve that sews over the ears and slide/sew it onto the headband.

- decorate: Sew on bows, ribbons, beads or sequins. Attach studs or charms. Let your creativity run wild!

Conclusion: The magic is in your hands

3D printing opens up an unparalleled avenue for personal expression. Creating your own mouse ears isn’t just about making a fun accessory; It’s a journey of design thinking, problem solving, and turning a unique vision into reality. Whether you choose to print vibrant, playful PLA ears at home or envision stunning, lightweight ears made from titanium glorious Precision metal printing and finishing services, the results are unique. Embrace the process, learn from iterations, celebrate flaws as they are ironed out, and wear your creations with pride! Keep designing, printing, and visiting the Magic Kingdom—or wherever your imagination takes you!

FAQ (Frequently Asked Questions)

-

Can I legally sell 3D printed mouse ears?

- you can sell ears your own original design. The unauthorized use of copyrighted characters, logos or trademark symbols (such as the famous mouse silhouette) is an illegal infringement. Focus on unique patterns, shapes and themes.

-

What materials are best for comfortable, durable ears?

- For home printing: PETG offers the best balance of durability, ease of printing, and slight flexibility.

- For a premium feel: consider glorious Metal printing services. Materials such as aluminum or titanium combined with professional smoothing/polishing provide unparalleled lightness, strength and luxury.

-

My ears keep breaking at the connection point! help!

- Redesign: Significantly thicker clip/base. Add fillets/fillets at stress points. Print reinforcements such as extra layers or ribs underneath. Orient the print so that the layers are parallel to the headband for increased strength.

- Material: Switch from PLA to PETG or PETG-CF (carbon fiber filled for stiffness). If strength is the most important thing glorious Metal printing offers exceptional durability.

-

How do you get a super smooth, shiny, professional finish?

- plastic: Repeating the primer sanding (tapering grit) cycle before applying/sealing chemical smoothing (acetone vapor for ABS only, not PLA/PETG) is key, but requires caution. Metal: Metal printing inherently has the potential to be smoother. Services such as huge light Focus on advanced technologies such as CNC machining of specific surfaces, flow/polishing vibration finishing, micromachining, precision electropolishing or mirror polishing – achieving smoother, glossier surfaces than plastic FDM printing.

-

Can GreatLight print my custom plastic design?

- although huge light Specializing in advanced Metal Rapid prototyping using SLM technology, with a focus primarily on metals (aluminum, titanium, stainless steel, etc.). They specialize in transforming complex metal designs into tangible, high-performance parts. Additional FDM/SLS printing services exist for your plastic prototyping needs. connect huge light Acknowledge current products as functionality evolves.

- How much does it cost to professionally print metal ears?

- Cost depends heavily on design size/complexity, metal material selected, and post-processing finishing required. Metal printing services tend to be much more expensive than FDM plastic printing due to equipment/material costs. huge light Specializing in high quality, precision metal parts where lightweight strength and premium finish are critical. It is best to request a quote for your design.