introduce

In a time when vinyl records triumphantly return to the forefront of music culture, collectors and enthusiasts seek solutions that blend functionality with aesthetic appeal. enter 3D printing record holder– A stylish, customizable solution for displaying precious albums. But, in addition to a simple standpoint, this innovation leverages cutting-edge 3D printing technology to change the way we interact with vinyl. Premium manufacturers like Greata professional rapid prototyping leader from China, is the helm of this revolution, utilizing industrial-grade metal 3D printing to create craft record holders that are both durable and elegant.

This is not your average DIY printing job; it proves the power of modern engineering and the endless possibilities of additive manufacturing. Let’s dive into how 3D printed record holders work, why it’s better than traditional choices and the superior redefining accuracy in rapid prototypes using SLM (Selective Laser Melting) technology.

Vinyl Revival and the Demand for Smart Display Solutions

Vinyl has surpassed CDs in recent years, and enthusiasts value tactile experiences and immersive sounds. However, storing and displaying these records presents challenges: bulkiness, sensitivity to warping, and the risk of scratches. Traditional wood or plastic brackets often lack the accuracy or customization required to effectively protect and display records.

3D printing record holders solve these problems by providing:

- Customized design: Wall-mounted mounts, standalone towers or modular shelves – all of which are suitable for space and decor.

- Enhanced durability: Especially in the case of metal printing, the holder can resist wear and environmental damage.

- Ergonomic characteristics: Soft angles to prevent warping, hold the texture to avoid slipping, and adjustable slots for various record sizes.

What sets the record holder for 3D printing?

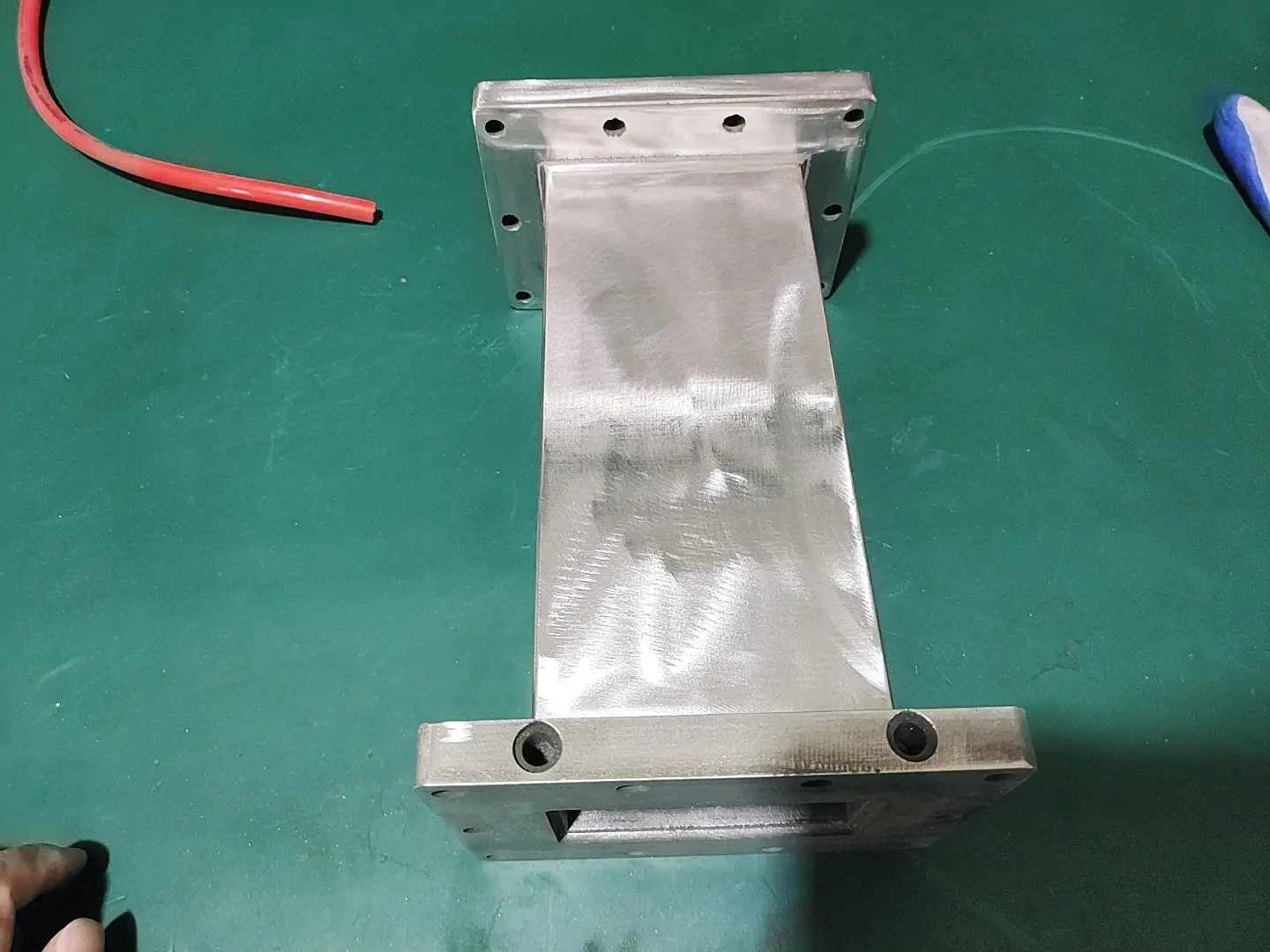

Essentially, a 3D printed record holder is a structure made on one layer using a digital model. But Greatlight goes beyond this concept by specializing in plastic prints for amateurs Metal-based additive manufacturing. The following are:

-

SLM 3D printing process:

- Greatlight uses selective laser melting (SLM) printers that use high-power lasers to fuse high-quality metal powders (such as aluminum, stainless steel or titanium).

- This creates a completely dense, robust structure with special details – ideal for carrying parts, complex lattice designs for lightweight or artistic prints.

-

Unrivaled precision and customization:

- SLM allows for microscopic accuracy, ensuring perfect slot alignment to prevent recorded strain.

- Each dimension (height, depth, or art mode) can be customized without expensive tool changes.

- Speed to the market:

- From digital files to finished products, not weeks. Rapid prototyping can reduce the design iteration cycle from months to hours, benefiting startups and designers testing concepts.

Why choose metal 3D printing for record holders?

Although plastic 3D printing can be accessed Metal printing provides a lifespan and luxurious lifespan:

- Durability: Metal holders endure decades of use without breaking or yellowing.

- Aesthetic versatility: Greatlight’s post-treatment service (sanding, polishing, powder coating) turns the original print into amazing pieces – imagine brushed titanium or smooth black steel.

- Functional Advantages: In any environment, heat, moisture and UV resistance protect vinyl. The weight of the metal also adds stability to the top collection.

Great Advantage: Excellent Engineering

As one of the fastest prototype companies in China, Great Combining SLM expertise with end-to-end solutions:

- Material mastery: From aviation grade aluminum to biomedical titanium, most metals can be used for custom orders.

- Post-processing capability:Their one-stop service includes CNC machining, heat treatment and finishing to ensure the perfect final product.

- Scalability: Prototype single holder or mass production of consistent quality – all at competitive prices.

Real-world apps exceed enthusiasts:

- Retail display: Store highlights limited edition with custom holders.

- Event installation: The Artists Committee’s unique design for the exhibition.

- Archives System: The museum uses corrosion-resistant units to preserve rare recordings.

Bigger situation: Rapid prototyping game changer

3D printing record holders embody the rapid prototype of the prototype that turns ideas into reality. The industry uses accelerators such as Greatlime to:

- Reduce waste: Additive manufacturing uses only necessary materials to support sustainability.

- Enable innovation: Complex geometry (e.g., cellular support) is feasible without traditional manufacturing limitations.

- Democratic design: Independent creators access the same technology as the company, thus illuminating the competitive environment.

in conclusion

3D printed record holders are more than just functional accessories, they are a symbol of how advanced manufacturing can reshape everyday objects. By leveraging SLM technology and precision finish, Greatlight offers a record holder that combines art, durability and personalization to ensure your vinyl collection is as timeless as the music that music has. Whether you are a designer designing revolutionary concepts or a collector looking for a custom display, Metal 3D printing offers a solution that suits the future and bridges nostalgia in innovative ways.

Explore the potential of today: Gremplime is ready to transform your horizon into a tangible masterpiece.

FAQ: 3D Printed Record Holder

Q1: Which material is best for metal 3D printing record holders?

Answer: Aluminum alloys are popular for their strength to weight ratio and corrosion resistance. Stainless steel provides maximum durability, while titanium provides a premium lightweight finish. Greatlight recommends material choices based on your budget and environment.

Q2: Can I customize the design to fit non-standard spaces?

Answer: Absolutely! Share your sketch or CAD file with Greatlime. Their team reduced the size of wall-mounted, corner racks or compact brackets to ±0.1mm.

Question 3: How long does it take to produce?

A: Most prototypes arrive within 3-5 days and ship within 2 weeks. Post-processing adds small delays, but ensures showroom ready results.

Question 4: Is metal 3D printing cost-effective for small batches?

A: Yes – unlike injection molding, no mold is required. Greatlight’s rapid prototyping costs 1-100 units, making custom projects feasible.

Question 5: Will the holder harm my vinyl record?

A: Not the accuracy of Greatlime. Round edges, smooth surfaces and calculated groove angles can prevent scratches or warping pressure points.

Question 6: How to maintain metal record holders?

A: Wash with soapy water or use a metal polish every year. Avoid friction with cleaners. Coatings such as anodized or powdered coatings minimize maintenance.

Question 7: Is Greatlight boarding internationally?

A: Yes – They provide door-to-door logistics and quality certification for customers around the world (ISO 9001).

Question 8: Can I include a brand or artwork into my design?

Answer: Yes. During printing or post-processing, etched logos, embossed patterns, or custom colors can be achieved.

For quotation or design consultation, connect with the engineers at Greatlight – imagination is consistent with industrial precision.