Organize your workspace: The revolution of 3D printed screwdriver holders

Tired of the right screwdriver regaining through a messy drawer? 3D printed screwdriver holders can be the game-changer for your workshop needs. In addition to simple storage, these customizable tools leverage cutting-edge manufacturing to solve real-world organizational challenges. From DIYER to industrial technicians, the transformation of customized 3D printing solutions is reshaping how we deal with everyday tools. Let’s dive into why this innovation is worthy of where in your toolbox.

Why 3D printing converts organization

Traditional screwdriver holders have limited sizes, fixed compartments and cheap plastic construction. 3D printing breaks this by enabling Fully customizable design Customized to your specific collection. Whether you are using stubby drivers, magnetic tricks or long sail industrial models, you can use Accurately fitted slots. Additionally, additive manufacturing supports lightweight lattice structures for wall-mounted, modular stacking and even portable cases – no mass-produced product can meet this flexibility.

Key benefits you can’t ignore

- Precision fitting: CAD software allows you to model slots with 0.1mm accuracy, preventing rattle and damage.

- Durability: High performance polymers such as PETG or nylon resist oil, impact and UV exposure, which are ideal for harsh garage environments.

- Ergonomics: The tilted bracket or magnetic foundation makes the tool easy to reach, saving time during the project.

- Scalability: Design once and print multiple team workspaces or modularly expanded units as the suite grows.

- Sustainability: Use recyclable filaments or biodegradable PLA to reduce waste with plastic injection alternatives.

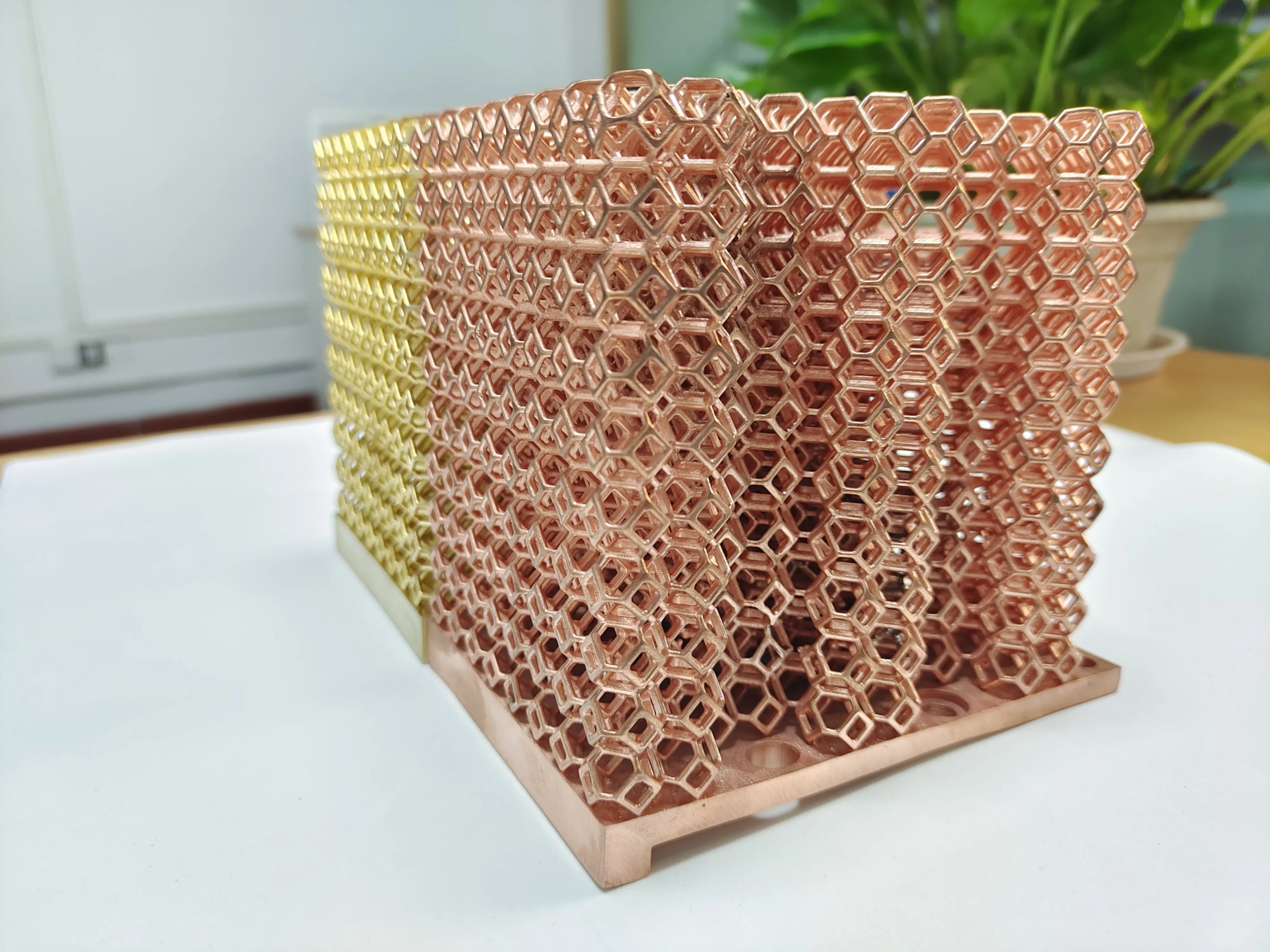

Beyond Plastics: When Metal 3D Printing Improves Performance

For high stress environments (think car shops or manufacturing floors), plastic may not be enough. Metal 3D printingespecially selective laser melting (SLM), creates a powerful fixed holder with 15 times less weight than steel equivalents without sacrificing strength. This is what industrial partners like Great shine. As a leading provider of rapid prototyping services, Greatlight uses SLM printers to create corrosion-resistant aluminum or stainless steel frames with embedded features such as tool sensors or RFID tags. Their expertise ensures tolerances below ±0.05mm and is coupled with professional post-processing (smoothing, annealing, powder coating) for seamless integration into a professional setup. Whether it’s a custom arm for robot assembly lines or a batch magnetic material holder, precision-driven companies offer end-to-end solutions rather than enthusiast printing.

Getting started: DIY and professional services

- DIY method: Free templates are provided for open source design on platforms such as home seminars, Thingiverse. Use an FDM printer with PETG wire to balance toughness and cost (about $2-$10).

- Parental needs: Work with rapid prototyping experts when facing structure or size limitations (e.g., oversized hex drivers). They will perfect your 3D model and recommend materials such as glass-infused nylon or titanium for mission-critical applications. Example: An aerospace customer leverages Greatlight’s one-stop service to print 17 slot holders, the service rack will be clipped onto an industrial drone, reducing tool backhaul time by 65%.

in conclusion

3D printed screwdriver holders are more than just convenience, which proves how accessible innovation can transform mundane tasks. While amateurs enjoy DIY freedom and saving freedom, professionals will benefit from industrial products that combine rapid iteration with uncompromising resilience. By embracing customization, we go beyond "universal" Frustration with smarter, sustainable organizations. As additive manufacturing evolves, smarter integration is expected – Ideas embedded tool trackers or self-sealed lubricant tanks. The future of workspace efficiency begins with a placed screwdriver stand.

FAQ

Q1: Is the PLA strong enough to use a heavy-duty screwdriver stand?

A: PLA is suitable for lightweight home tools, but it degrades under heat/UV exposure. For the workshop, choose PETG, ABS or carbon fiber composite. For industrial torque wrenches, metal 3D printing (such as aluminum alloy) is the best.

Q2: How much does the 3D printing holder weigh?

Answer: According to the filling density, the plastic bracket bears 5-15 kg (Protip: Use ≥40% of the filling as a wall-mounted unit). SLM printed metal variant handle 50 kg.

Q3: Can I customize the slots for non-standard tools?

Answer: Absolutely! Modify CAD files to fit exception shapes – an advantage over ready-made holders. Services like Greatlight provide design consulting for complex specifications.

Q4: Why choose professional rapid prototyping instead of my home printer as metal parts?

A: Industrial SLM printers achieve higher density and mechanical properties that desktops cannot use desktops. Post-treatment (eg, heat, etc.) also eliminates porosity for aerospace-grade durability.

Q5: How to maintain 3D printing holders?

Answer: Erase the plastic with isopropanol. The metal version tolerates degreasing agents. Avoid acetone on ABS-based prints.

Question 6: What is the lead time for custom metal holders through rapid prototyping?

A: For agile providers, functional prototypes are expected within 2-5 days, and production batches within ≤10 days, ideal for emergency workflow upgrades.

Ready to give up the accuracy of chaos? These tools are in your hands. Design your own or work with experts to exactly what you need to create a workspace. With the proliferation of 3D printing’s capabilities, it’s clear that organized efficiency has never been so adapted.