The fascination of 3D printed suppressors: Understanding complex realities and significant risks

The digital revolution, led by accessible technologies like 3D printing, is democratizing manufacturing like never before. From intricate works of art to functional prototypes, the capabilities are seemingly limitless. This accessibility inevitably extends to more sensitive areas, including gun accessories. Among them, the concept of 3D printed suppressors (often mistakenly referred to as "silencer") has aroused great curiosity online. However, before succumbing to such curiosity, it is crucial to peel back the layers and face the significant technical, legal and ethical risks involved. As a professional rapid prototyping manufacturer, committed to industry progress Legal and responsible frameworks (such as GreatLight’s SLM metal printing), we feel the need to discuss this topic clearly and carefully.

Beyond Clicks: DIY’s Technological Risks of Curbing Printing

While 3D printing excels at rapid iterations of prototyping, using it to produce functional suppressors for live ammunition has inherent dangers that are often underestimated:

-

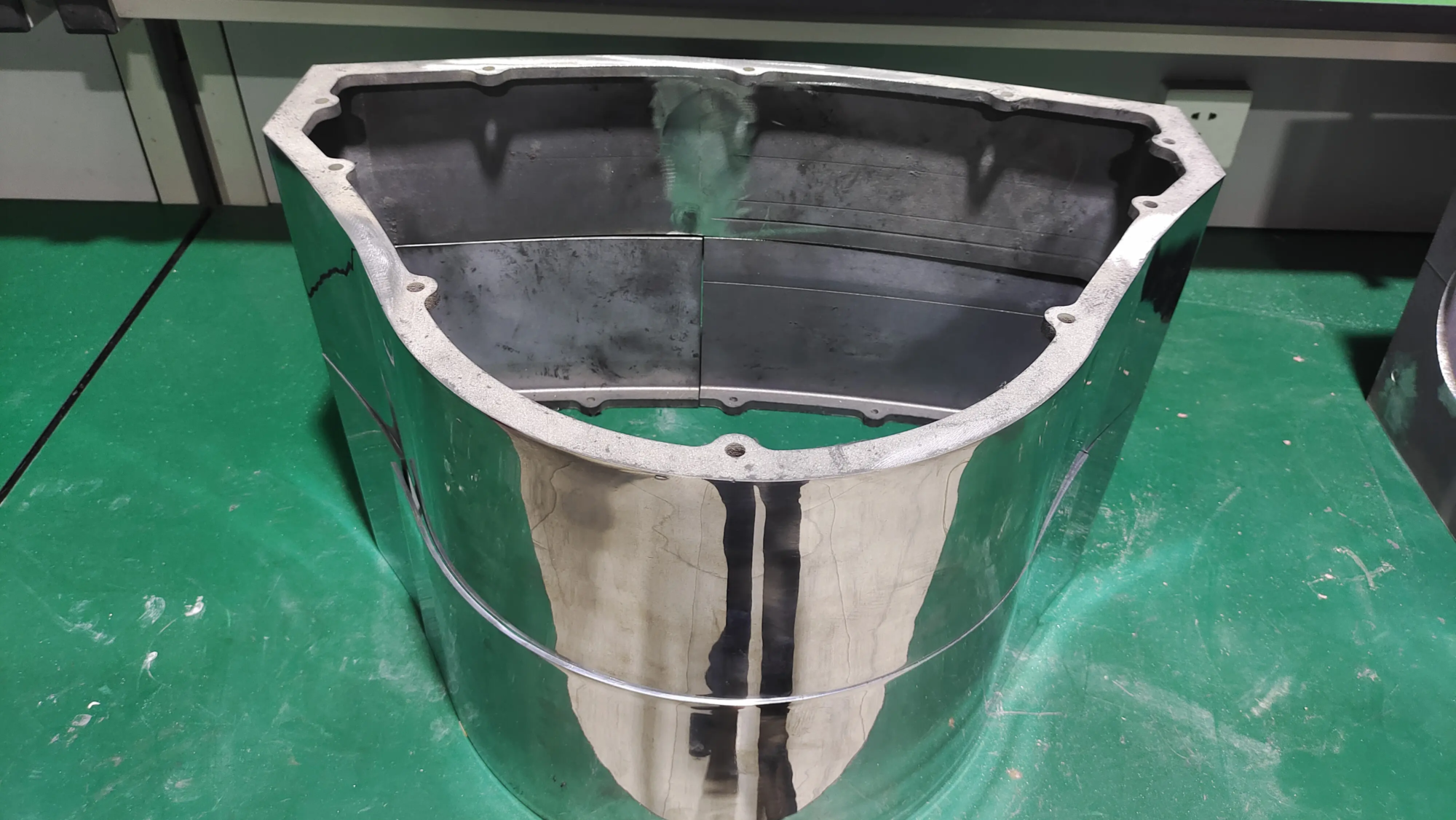

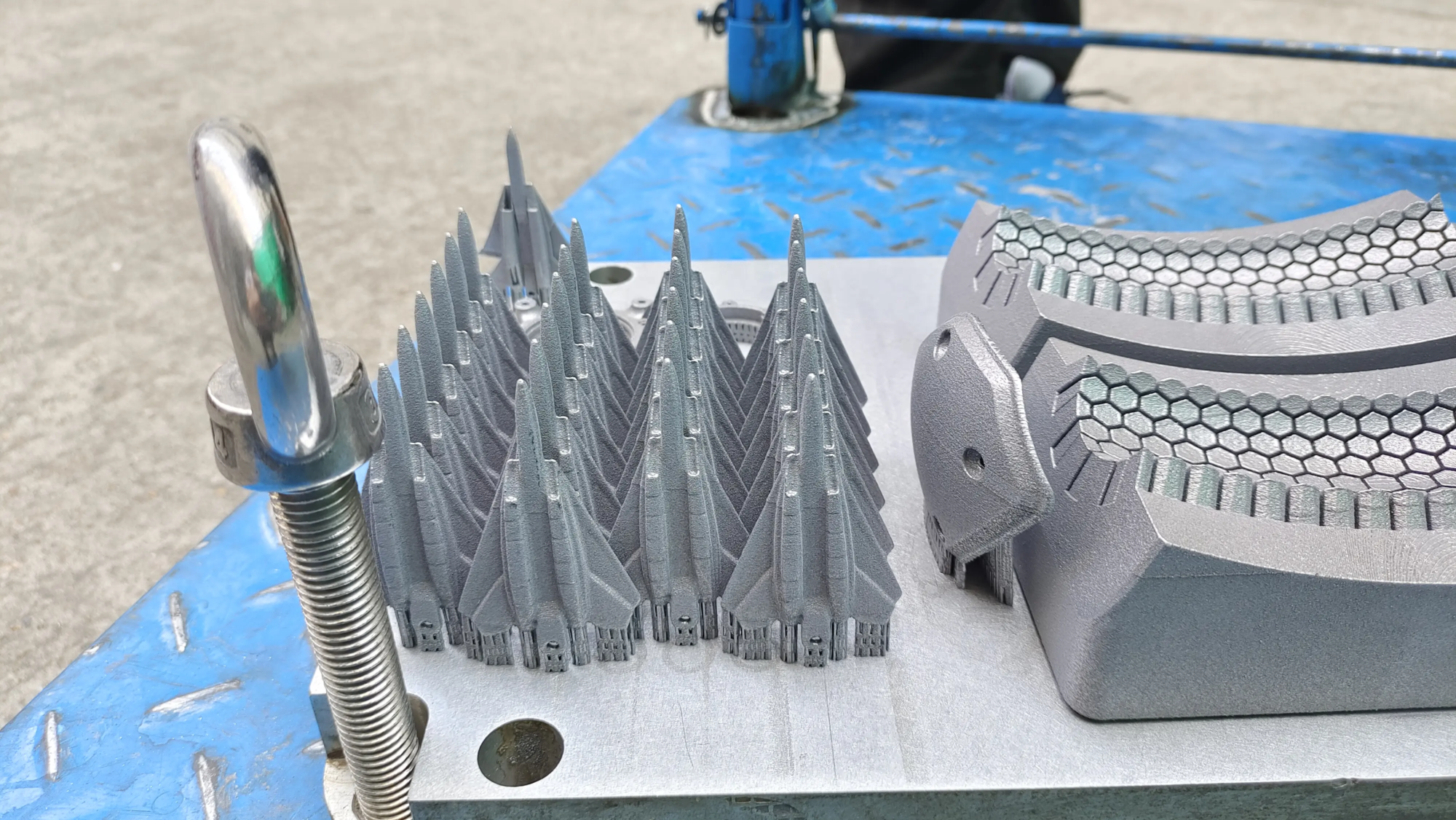

Material limitations and catastrophic failure: Consumer grade printers often use plastics (PLA, PETG, ABS) that are completely unsuitable for the extreme pressure (often over 50,000 PSI) and heat (over 1000°F/538°C in milliseconds) produced by rifle rounds. Even specialized high-temperature plastics or basic metal wires often lack the necessary tensile strength, fatigue resistance and heat resistance. The result isn’t quiet operation—it’s violent, unpredictable explosions Just inches from the user’s face and hands. Structural failure could eject shrapnel, damage the firearm and cause serious injury or death. While advanced metal additive manufacturing (SLM – Selective Laser Melting) using materials such as Inconel or specialty steels can theoretically achieve the required strength, the cost, complexity and expertise involved far exceed typical levels "DIY" projects and highly regulated industrial processes.

-

Design complexity requires precision: Effective suppression involves complex internal geometries (baffles, chambers, expansions) designed to gradually slow down and cool the gas. Simulating the airflow dynamics and pressure distribution under these extreme conditions requires sophisticated computational fluid dynamics (CFD) software and deep engineering expertise. Subtle, hard-to-detect design flaws in CAD models can lead to inefficiencies or, worse, catastrophic stress concentration points. "print and pray" Method is a recipe for disaster. Verifying such designs requires expensive test equipment and controlled environments that are well beyond the capabilities of amateurs.

-

Manufacturing Defects and Process Variations: Layer-by-layer printing introduces potential weaknesses not found in traditional processing or welding suppressors. Porosity (tiny air bubbles), insufficient layer adhesion (especially important in metal processes like SLM where precise thermal control is required), warping, inconsistent filling, slight nozzle clogs or slight temperature fluctuations during printing – all of these can create critical, invisible failure points. The requirement for post-processing of metal printed parts (such as heat treatment or hot isostatic pressing – HIP) to eliminate porosity and achieve full density adds another layer of complexity that is often missing from online instructions.

- Performance and durability flaws: Even if the printed plastic suppressor miraculously survived the first shot without exploding, its longevity would be negligible:

- Deforms almost immediately under heat and pressure, reducing performance.

- Each subsequent shot rapidly melts or corrodes the baffle.

- Gas often escapes through the layer lines and the volume can remain dangerously high.

- The equipment quickly becomes unusable and falls far short of the reliable performance expected of professional manufacturing equipment.

Navigating legal minefields

The extremely serious legal environment exacerbates technological dangers:

-

Strict supervision (US perspective – NFA): In the United States, suppressors are strictly regulated under the National Firearms Act of 1934 (NFA). This requires:

- Revenue stamps and registration: Individuals must pay a $200 tax per suppressor and undergo an extensive background check (Form 4 for transfers, Form 1 for home manufacturing).

- Pre-approval: possess or make No Pre-approved registration is federal felonypunishable by up to 10 years in prison and a hefty fine.

- National legitimacy: Even with NFA approval, many states completely prohibit civilian ownership of suppressors. Ignorance is not a defense.

-

critics "destructive device" the difference: manufacturing any suppressor "part" (like a flapper or cup) intentionally Suppressor components "make" NFA projects and require prior approval. Just have the CAD file and The right printer Can This may be construed as intentional in some cases, thereby increasing legal risk.

-

International differences: Laws vary widely around the world. Without a license, possession or manufacturing may be severely restricted or prohibited entirely (e.g., in most of Europe, Canada, Australia) or heavily regulated as in the United States. Assuming legitimacy based on online forums is dangerously naive. A thorough research of local, state, and national laws is an absolute necessity, not a recommendation.

- Digital fingerprint: Downloading, possessing or sharing suppressor-specific CAD files may draw scrutiny from law enforcement, especially in areas with strict regulations. Digital forensics provides ample clues.

Ethical and safety requirements

Beyond the legal technicalities, there are core ethical responsibilities:

- Personal safety: As mentioned above, the risk of catastrophic failure resulting in injury or death to users or bystanders is not hypothetical – it is a possible result of untested, substandard printing equipment.

- Potential for criminal abuse: Suppressors can (illegally) achieve more efficient criminal activity by reducing reporting signatures. Promoting unregistered manufacturing can indirectly create public safety risks.

- Undermining responsible innovation: Reckless attempts and subsequent failures have negatively impacted the entire 3D printing and rapid prototyping industry, hindering its legitimate applications in aerospace, medical devices, and engineering.

Where does responsible 3D printing fit in (GreatLight Niche)

risk Fully functional, not tested The 3D printed suppressor is transparent. However, the power of additive manufacturing in related fields law and ethics Applications should not be ignored in professional contexts:

- R&D prototype: Research laboratories and licensed manufacturers are exploring New suppressor design Advanced SLM metal printing can be leveraged to quickly iterate and test geometries and materials under strictly controlled laboratory conditionssignificantly speeding up the development cycle before final production through traditional methods. (This is where GreatLight’s expertise in SLM metal printing and post-processing provides value – solving complex rapid prototyping challenges legal engineering progress).

- Safe copy: Using plastic to create non-functional models for display, training props, movies or airguns is legally different, but requires extreme caution and clear marking/distinction from functional equipment.

- Mechanism test: Design/Test attachment system Although legal awareness remains critical, suppressors (mounts, threads, boosters) on an inert platform allow for safe exploration.

Conclusion: Innovation and Responsibility

effortless concept "print" Sensationalism and misunderstandings about technological capabilities and the regulatory environment often fuel disincentives. The harsh reality is that trying to 3D print a functional suppressor at home:

- extremely dangerousa high risk of catastrophic failure and serious injury due to defects in materials and design.

- is illegal In many jurisdictions, the lack of proper, difficult-to-obtain licensing and registration carries severe felony penalties.

- Requires engineering expertise and industrial-grade metal additive manufacturing Far beyond consumer desktop printers and even close to security features.

Innovation in any field, especially one closely related to public safety, requires responsibility and strict compliance with regulations. At GreatLight, we champion the transformative power of advanced 3D printing (SLM) to enable rapid prototyping and professional manufacturing. However, we explicitly advocate its use only within legal and ethical boundaries, prioritizing safety, rigorous testing, and compliance.

The technological frontier offers incredible potential, but handling sensitive applications such as firearm accessories requires wisdom and caution. Prioritize safety, understand the law, and use expertise responsibly.

FAQ: Burning questions about 3D printed suppressors

Q1: Can I legally 3D print a suppressor at home for personal use?

- one: In the United States, only if You have received a pre-approved ATF Form 1 Stamp Authorization Specifically Make this suppressor. It is a federal felony to manufacture or possess an unregistered suppressor. Laws vary widely internationally; many countries prohibit civilian possession of suppressors entirely. Never assume legality; always consult official local, state, and federal sources.

Question 2: If I paid a revenue stamp (Form 1), is it safe to print one on my home FDM printer?

- Answer: Absolutely not. Even with legal registration (granting of license Productionnot necessarily safe), consumer plastic printing materials (PLA, PETG, ABS) lack the thermal and structural properties to withstand the pressure and heat of a firearm for any meaningful length of time (if at all). Malfunction has a high probability of causing injury or death. Table 1 Approval does not mean that unsafe behavior becomes safe. Licensed Form 1 manufacturers overwhelmingly use solid machined metal components.

Q3: What about using the online downloadable suppressor files?

- one: Downloading, possessing or sharing such files may attract intense legal scrutiny, especially if combined with evidence of manufacturing intent (such as having the appropriate printer and materials). Documentation specifically designed for a suppressor is a dangerous red flag to law enforcement. Legality varies by jurisdiction, but there are inherent risks.

Q4: Is 3D metal printing suppressors more feasible? If so, where can I get one?

- one: Advanced metal additive manufacturing (such as SLM using Inconel or titanium) able Produce functional inhibitors. However, this requires millions of dollars worth of industrial-grade equipment, expertise in design and process engineering (powder handling, melting, heat treatment/HIP) and extremely stringent quality control. This is Not a DIY endeavor. Licensed manufacturers can commercially produce metal-printed suppressors, but they must undergo a rigorous ATF approval process (Form 3, Form 4) and testing (such as more than 100,000 rounds of durability testing). Therefore, they are expensive niche products. Well-known professionals like GreatLight who specialize in industrial prototyping will do no Engaging in unregulated or unsafe manufacturing practices, particularly involving controlled items such as suppressors.

Q5: Can GreatLight 3D print a suppressor for me?

- one: No, GreatLight cannot and will not undertake the 3D printing of functional suppressors or suppressor design components. We strictly comply with all local and international laws and regulations regarding the manufacture and export of controlled items, including firearms parts and components. Our expertise lies in Legal and ethical rapid prototyping and production Use advanced technologies such as SLM to manufacture metal parts for industries such as aerospace, automotive, medical and industrial machinery. We provide solutions to legitimate engineering challenges within the bounds of law and responsible practice.

Q6: What are the legal uses of 3D printed suppressors?

- one: Valid applications include:

- Authorized Manufacturer/R&D Lab Prototyping new design Use metal printing (such as SLM) in a controlled environment following strict testing protocols.

- Create non-functional replicas or display models (clearly marked as such).

- Prototype/test external mounting mechanisms on fake firearms or fixtures.

Always put safety and legality before curiosity.