Embrace custom organization: The revolution of 3D printing switch game stand

Keeping the organization of Nintendo Switch Game Game Cartridges in the bustling gaming world is a common challenge. Those small ink cartridges are easily lost in the sofa cushion, mixed with other accessories, or spread casually on the table. Enter innovative solutions: 3D Printing Switch Game Stand. This is more than just another storage box; it’s a custom-made high-precision accessory that combines functionality, durability and personal style. And adopt cutting-edge manufacturing technologies such as selective laser melting (SLM) and advanced polymer printing Perfect The holder has never been easier to obtain, or more impressive.

Why 3D printing improves your gaming storage

3D printing transforms the mundane task of storing switch cartridges into opportunities for customization and engineering excellence.

- Super personalized: Unlike mass-produced plastic brackets, 3D printing allows you to design a bracket around it your collect. Do you need 8 cartridges for space? 16? 32? no problem. Add tags, favorite game logos, ergonomic grips and even theme shapes (like Triforce or Poké Ball). You can control each dimension, slot depth and aesthetic details.

- Material versatility: Choose from a range of materials to meet your needs:

- Engineering Plastics (PLA, PETG, Nylon): Lightweight, colorful and impact-resistant, it is very suitable for casual use.

- Metal alloy (aluminum, stainless steel): For high-end, heirloom quality feel. SLM 3D printing produces holders with excellent strength and stylish, professional surfaces, perfect for gamers who need durability and luxury.

- Rapid prototype and iteration: Tests are used for prototyping that takes weeks. With Greatlight’s advanced 3D printing capabilities, you can perfect your holder’s ergonomics, fit and visuals in just a few days. If slot A feels too tight or needs to be rounded, the revision will be fast and cost-effective.

- Non-mobile economics: Skip the expensive injection molding settings. 3D printing allows for small batch production without up-front tool costs, making custom design affordable for individuals or small businesses.

Engineering Perfect Holder: Key Design Considerations

Creating reliable game holders goes beyond aesthetics. This is the priority for professionals:

- Precision cartridge fit: Switch cartridges are standardized, but friction tolerance is important. The slot designed with ±0.1mm accuracy ensures the cartridge slides smoothly without swaying or scratching. Greatlight’s SLM and polymer printers can repeatedly implement these tolerances.

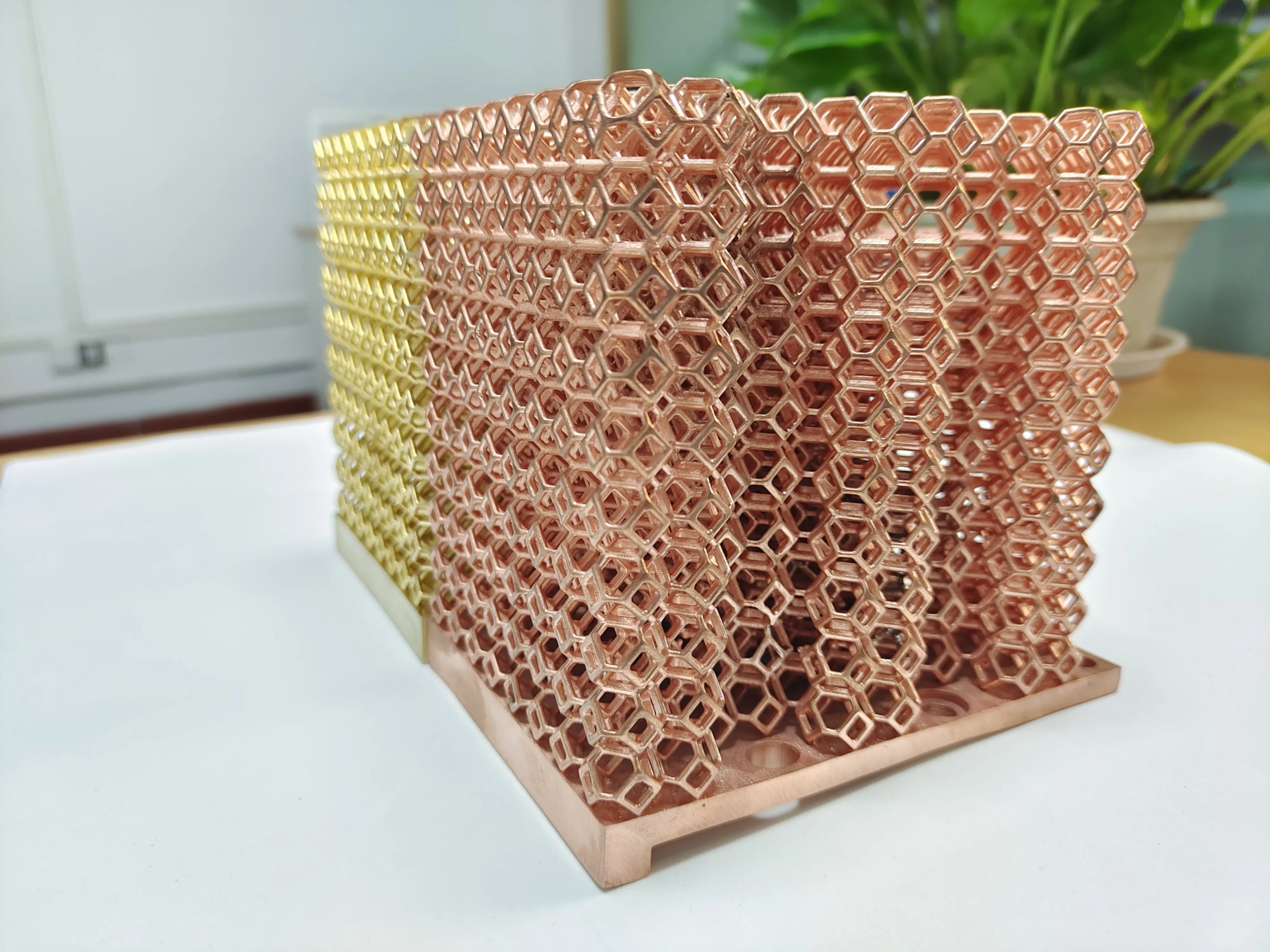

- Structural integrity: The holder should not break under pressure. For plastic prints, fill density (15-30%) increases stiffness. For metals, the lattice structure optimizes the weight to strength ratio. Inclined walls and reinforced bases prevent warping.

- User Experience (UX): Finger access gear, stackable segment, anti-slip base and compact portability enhance usability. Some designs integrate a drawer mechanism or protective cover, which is ideal for travel.

- Aesthetic finishing: Post-processing issues. Options include matte matte texture, polished wire, vibrant plastic or protective sealant. Greatlight’s one-stop sorting service ensures that your holder looks as tall as it looks.

Why collaborate for your 3D printing game holder?

exist GreatWe are more than just manufacturers; we are professional partners who turn your vision into reality. Here’s our excellent way:

- Industrial technology: Our facilities and housing are advanced SLM 3D Printer Ability to make complex metal holders with precise accuracy with high resolution polymer systems.

- End-to-end expertise: From CAD file optimization to final completion (grinding, anodizing, powder coating), we manage each step. Our engineers make sure your design is manufactured and practical.

- Material mastery: Enter more than 50 metals (aluminum, titanium, tool steel) and polymers. We choose materials according to your needs – resistance to sunrooms, safety biocompatible plastics or lightweight alloys for travel.

- No compromise on speed: Need to do prototypes within 48 hours or 100 batches per week? Our fast turnarounds handle emergency projects while maintaining accuracy and quality.

- Dietary focus solutions: As a leader Rapid Prototyping Manufacturer From China, we give priority to it Expertise, authority and credibility. Each project is strictly quality checked and complies with global ISO standards for consistency and reliability.

in conclusion

The 3D printed switch game stand is a microcosm of how the zoom manufacturing method reshapes everyday objects: merge custom designs with industrial-grade performance. This is your upgrade for gamers tired of fragile solutions. By leveraging precise technologies like SLM and polymer printing, you can unlock unlimited customization from rugged travel boxes to elegant display pieces. Great Be prepared to improve your ideas. We not only build parts; we solve problems through speed, innovation and unwavering quality. Whether you are an amateur, independent designer or retailer, work with us to create a holder that is as good as the game library.

FAQ (FAQ)

Q: How durable is the 3D printed game holder?

Answer: Extremely. Polymer holders who use PETG or nylon to resist droplets and daily wear. Metal holders (for example, through SLM through aluminum) are nearly indestructible under normal use and have excellent scratching properties.

Q: Can I design a holder myself, or do I need engineering skills?

A: GRESTLIGHT supports both! Share your Sketchup/Blender file, or have our design team create a model from your sketch. We optimize it for printability and functionality.

Q: How much does it cost to customize the holder?

A: Cost varies by size, material and finish. Simple plastic stands start as low as $15; metal design with polish can reach $50-$100. We offer quotes within 24 hours.

Q: Which file format do you accept?

A: We use STL, OBJ, step and IGES formats. Need help with formatting? We will help!

Q: How long does it take to produce?

Answer: The polymer prototype takes 2-3 days. Metal holder by SLM: 5–7 days. Shipping in batches within 1-2 weeks. Urgent? An expedited selection is available.

Q: Do you provide anti-slip or protection?

Answer: Yes! During post-processing, add a rubber base, sweater lining, silicone compartment or snapshot cover. Just specify your needs.

Q: Are your materials environmentally friendly?

A: We provide recycled polymers and metals. Send us information about sustainable choice!

Ready to organize the game in an unparalleled style? Contact Greatlight for free design consultation – Imagination is in line with industrial-grade innovation.