Titanium’s Transformation: Revolutionizing Manufacturing with 3D Printing

Imagine a world where aerospace components push weight limits, medical implants integrate seamlessly with human bones, and industrial tools can withstand extreme conditions like never before. This isn’t science fiction – this is reality 3D titanium printing revolution. Essentially, this transformation takes advantage of the extraordinary properties of titanium and combines them with the precision of modern additive manufacturing. Titanium alloys have long been coveted for their exceptional strength, lightweight properties and biocompatibility, but traditional processing methods often make them costly and have limited design scope. Now, 3D printing—especially Selective Laser Melting (SLM)——are breaking down these barriers and opening up new fields of engineering.

Why choose titanium? power metal

The beauty of titanium lies in its unique properties:

- Strength to weight ratio: 45% lighter than steel but just as strong.

- biocompatibility: An implant ideally suited to integrate with the human body without rejection.

- Corrosion resistant: Able to withstand harsh environments from aerospace to chemicals.

Traditionally, processing titanium is a slow and wasteful process, with up to 90% of the raw material ending up as scrap. Complex design? Almost impossible. 3D printing eliminates these limitations, building parts layer by layer from titanium powder with surgical precision.

SLM: The engine of the titanium revolution

Selective Laser Melting (SLM) It is the gold standard for titanium additive manufacturing. Here’s how it transforms powdered metal into high-performance parts:

- Laser precision: A high-power laser selectively melts titanium powder particles in a controlled atmosphere.

- Fusion layer by layer: Complex geometries (internal channels, lattices or organic shapes) are built with micron-level precision.

- Minimize waste: Unmelted powder is recycled, reducing material waste to near zero.

Unlike earlier metal printing methods, SLM production Function-intensive part Mechanical properties are comparable to forged titanium. Modern innovations, such as multi-laser systems and artificial intelligence-driven process control, now ensure consistency even in complex designs.

Edges of 3D printed titanium parts

SLM-driven titanium workflows deliver game-changing advantages:

✅ Design freedom:Creating aerodynamic aerospace scaffolds with topology-optimized weight reduction or patient-specific spinal implants with porous surfaces to promote bone ingrowth—none of this is possible with CNC.

✅ Speed and agility: Prototyping takes days instead of months, speeding up development cycles.

✅ Cost effective: Mass production, reducing tooling costs and minimizing waste, cutting the cost of complex parts by up to 70%.

✅ Enhance performance: Parts consolidated assemblies (e.g., 10+ parts into 1), reducing points of failure while maintaining durability in extreme stress/temperature environments.

Industry-wide applications

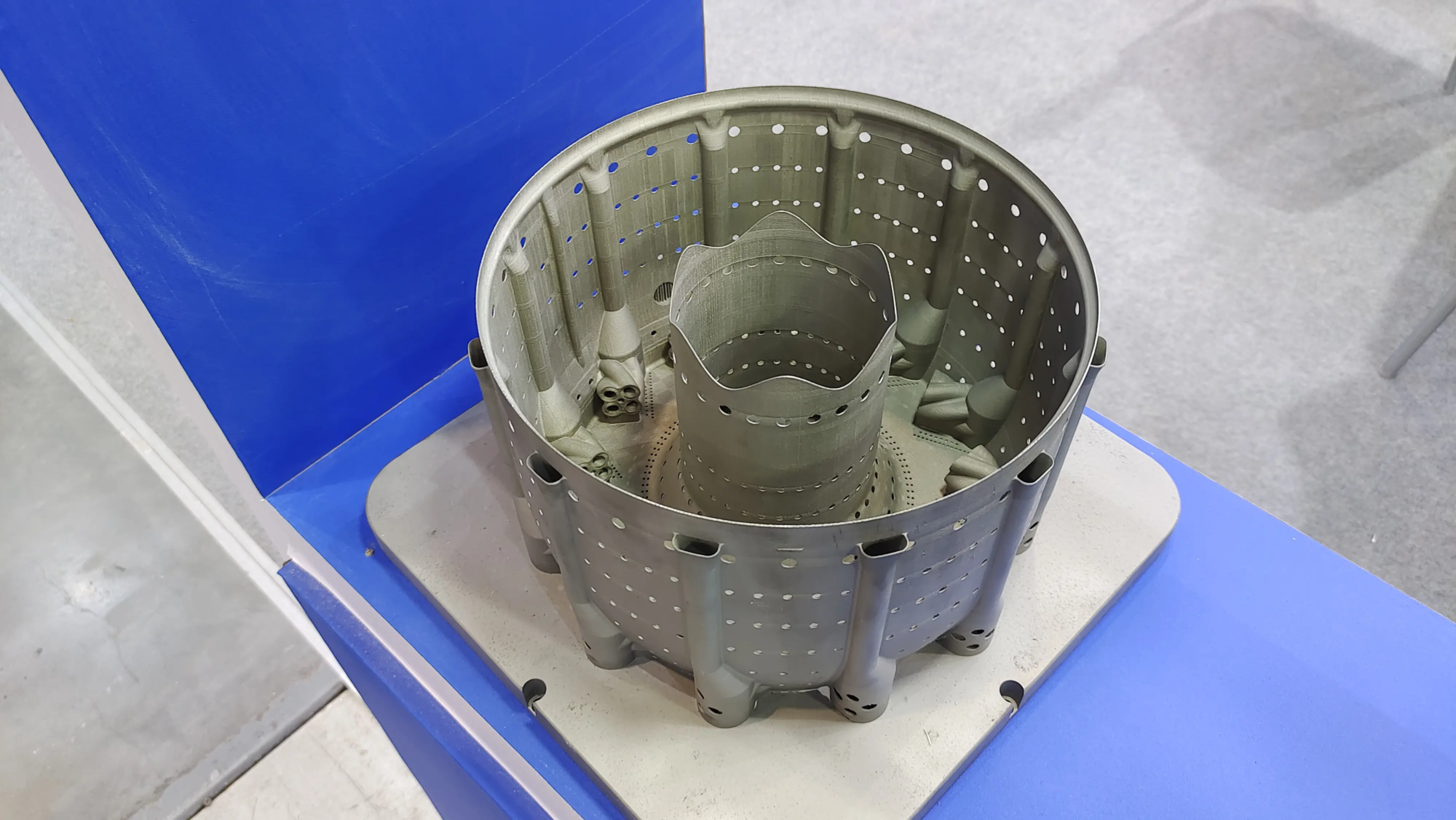

- aerospace: Turbine blades, satellite components and structural accessories take advantage of titanium’s lightweight properties to save fuel and reduce emissions.

- medical: Hip cups and dental implants take advantage of titanium’s biocompatibility and can be customized using CT scan data for a perfect anatomical fit.

- car: High-performance engines use titanium valves and connectors for durability under high temperatures and pressures.

- industrial: Corrosion-resistant heat exchangers and tooling molds for electronic products.

illustration: A helicopter manufacturer used SLM-printed titanium to reduce a hydraulic manifold assembly from 20 parts to 1, reducing weight by 35% and shortening assembly time by 80%.

Obstacles and how to overcome them

Printing in titanium is not without its challenges:

- residual stress: Managed through random laser scan paths and strategic support structures.

- Post-processing: Crucial for surface refinement and stress relief. The process is like HIP (hot isostatic pressing) Internal pores are sealed, while CNC or electrochemical polishing achieves a mirror finish.

- Quality assurance: Advanced industrial CT scans verify structural integrity layer by layer.

Companies specializing in titanium metal printing – e.g. huge light— has extensive expertise in navigating these nuances. With precisely controlled SLM printers and integrated post-processing workflows, they ensure aerospace-grade certification and repeatable quality.

Cooperation Progress: GreatLight’s Advantages

Navigating the complexities of titanium requires more than just hardware, it requires deep technical acumen. huge lightA leader in rapid prototyping from China, bridging this gap:

- Cutting-edge SLM technology: Advanced multi-laser SLM system processes large titanium parts with unparalleled resolution.

- End-to-end solution: From prototype design to mass production, including HIP, CNC finishing, coating and quality verification.

- Materials expertise: Titanium alloys customized for thermal, biomedical or structural needs (e.g. Ti-6Al-4V, Ti-64 ELI).

- Quick customization: Prototype turnaround takes just a few days, scaling up to volume production under strict EAT protocols.

GreatLight positions itself as an innovation catalyst, solving "impossible" Metal prototyping challenges while prioritizing affordability. Whether you require FDA-compliant implants in the medical technology field or design competition-critical automotive components, their turnkey approach can meet your needs.

Looking to the future

The 3D titanium printing revolution is evolving. Emerging trends such as AI-optimized lattice structure and hybrid manufacturing (rice