ISO 9001 Factory

ISO 9001 Factory

The world’s first CNC machining center that dares to provide free samples!

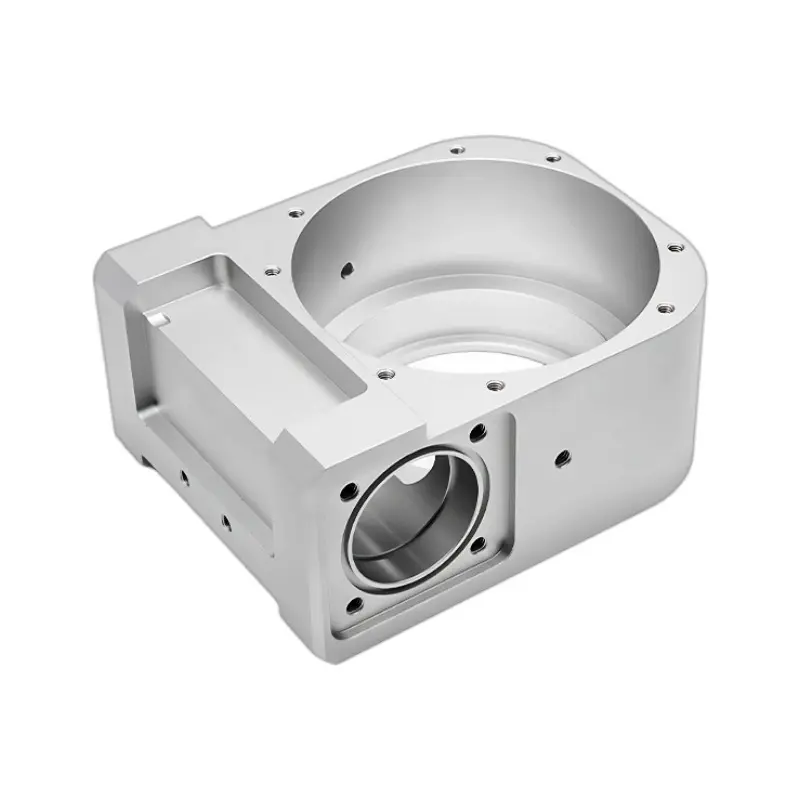

4-axis CNC machining strikes a balance between capability and cost, making it ideal for projects that need rotational movement without the extreme complexity of 5-axis work.

✅ Custom manufacturing of metal parts from prototyping to production.

✅ Prototype design and mass production within 3-5 days.

✅ 4 Axis CNC machining and forming of precision metal parts.

✅ Great Light CNC Machining ISO 9001 Certified Factory.

✅ ±0.001mm and above precision requirements can be processed.

4-axis machining allows for the machining of multiple faces of a part without manual repositioning, which reduces production time. This can result in faster turnaround times for projects that do not require full 5-axis capabilities.

4-axis CNC machines are generally more affordable while still providing more flexibility than 3-axis machines. This makes them a cost-effective option for jobs that need rotation but not extreme complexity.

4-axis machines excel at creating cylindrical parts and machining features around the circumference.

Since a 4-axis machine can rotate the workpiece to access different faces, it offers than a 3-axis machine for parts with multiple features on different sides.

One of the Best Rapid Prototyping Companies from China, Great Light CNC Machining Center is an ISO 9001:2015 certified manufacturer and is an excellent choice for custom metal and plastic parts. Whether you need a complex part made from a 3D design or a finished product for a high-level conference presentation, we can quickly produce prototypes and parts in a matter of days using 3-axis, 4-axis and 5-axis CNC machining.

CNC Manufacturing Experts

We use CNC to quickly process small and large-volume production orders for clients in a variety of industries: industrial design, automotive parts, robotic parts, prototypes, medical devices, aerospace, defense, electronics, hardware startups, industrial automation, machinery, marine, and more.

There is no limit on the order quantity and product value.

There are many types of materials for CNC processing. The main metal materials are: aluminum alloy, stainless steel, brass, various steels, titanium alloys, etc., which can meet the performance requirements of different materials.

One of the most important advantages of CNC prototypes is that its CNC processing accuracy is higher than other processing, and the maximum tolerance can reach ±0.001mm / 0.001 In, and multi-faceted structural products can be formed in one go.

CNC prototypes have high fidelity and high surface treatment level. After subsequent processing such as grinding, polishing, sandblasting, painting, silk screen, UV, electroplating, etc., the product effect is completely comparable to the products produced by the mold.

With years of manufacturing know-how, Great Light has covered you for CNC Machining and low-volume manufacturing.

Achieve the perfect finish with our range of surface treatments. Whether you require anodizing, plating, or painting, we ensure your parts meet both aesthetic and functional specifications.

Here’s what our satisfied customers have to say about how we met their needs, Their words speak louder than ours.

Designer

Thrilled with the fast CNC production and top-notch parts! Excellent service and flawless surface finishes. Great job!

Business Owner

The level of expertise of their engineers and their ability to complete these projects in a short period of time is commendable and worthy of recognition.

Designer

The results were outstanding. We were manufacturing a large housing component for an aerospace application with extremely complex hole geometry.

Business Owner

Had a great experience with GreatLight! Alice’s communication and dedication were excellent, and the product quality exceeded expectations. Highly recommend!

Businessman

They handled all aspects of this turnkey project quickly, professionally, and cost-effectively. We look forward to working with them again on future projects.

Business Owner

This is the most professional CNC service provider I have ever worked with and it has been a pleasure to work with them since day one. I have been in procurement for over 15 years and have worked on many projects with suppliers from all over the world.

Business Owner

I have been with them from the beginning and have seen this progress and I am very satisfied. Thanks again to all of you and everyone else behind the scenes for doing a great job.

Business Owner

Great Light can handle your CNC machining whether you need a few parts or over 10,000 end-use units. Check out the variety of custom CNC services we offer to take your designs from concept to reality quickly and accurately.

Our own internal processing capabilities: Five-Axis CNC 16 Units, Four-Axis CNC 12 Units, Three-Axis CNC 27 Units, CNC Milling & Turning 16 Units. If you have larger processing needs, we can also meet them.

4-axis CNC machining offers several advantages that make it a preferred choice for certain manufacturing needs:

Enhanced Precision and Complexity: The additional rotational axis allows for machining on multiple sides of a workpiece without manual repositioning, enabling the creation of intricate and detailed parts.

Improved Efficiency: With the ability to rotate the workpiece, 4-axis machining reduces the need for multiple setups, saving time and increasing production speed.

Versatility: It can handle complex geometries and features such as angled cuts, slots, and contoured surfaces, making it ideal for intricate designs.

Cost-Effectiveness: By reducing manual labor and setups, 4-axis CNC machining minimizes errors and waste, leading to cost savings over time.

Broader Applications: It's suitable for industries like aerospace, automotive, medical, and robotics, where precision and complexity are critical.

Choosing 4-axis CNC machining ensures high-quality, efficient, and versatile production for complex manufacturing needs.

The 4-axis CNC machining process involves several precise and coordinated steps to create complex parts. Here’s a breakdown of the process:

Design and Programming:

Engineers use CAD (Computer-Aided Design) software to create a 3D model of the part. This model is then converted into a CNC-compatible format using CAM (Computer-Aided Manufacturing) software. Tool paths and machining sequences, including rotation along the 4th axis, are programmed.

Material Setup:

The workpiece is secured on the CNC machine's rotary table or fixture. Proper alignment is crucial for accurate machining.

Tool Selection and Calibration:

Cutting tools, such as drills, mills, or reamers, are chosen based on the material and design. The machine calibrates these tools for precise movements.

Machining Operations:

Quality Inspection:

Once machining is complete, the part undergoes inspection to ensure dimensional accuracy and surface quality, often using tools like CMM (Coordinate Measuring Machines).

This efficient and precise process enables the production of complex, high-quality parts with minimal manual intervention.

Both processes have unique strengths, and the choice depends on the project’s design complexity, material requirements, and production scale.

The cost of a 4-axis CNC machined part varies based on several factors, including material selection, part complexity, production volume, and required tolerances. Here's a breakdown of these factors:

1. Material Selection:

2. Part Complexity:

3. Production Volume:

4. Required Tolerances and Finishes:

Estimated Cost Range:

Additional Considerations:

For precise pricing, it's advisable to consult with CNC machining service providers, as they can offer detailed quotes tailored to specific project requirements.

Maximum Dimensions (3-axis milling): 1500*800*300mm, 1270×508×635 (mm).

Maximum Dimensions (5-axis milling): 4000*400*150mm, 750x1150x550mm,

600*600*600mm, 500*500*450mm, 500*310*200mm,

Worktable Diameter Φ400 mm. All can be processed, and larger sizes can also be consulted by engineers

The surface finish produced by 4-axis CNC machining depends on factors such as tool type, material, cutting speed, and post-processing. Here’s an overview of typical surface finishes and what influences them:

4-axis CNC machining parts often undergo post-processing to achieve specific surface finishes:

Without post-processing, 4-axis CNC machining leaves a functional surface finish suitable for most applications. For enhanced appearance or reduced roughness, additional finishing processes like polishing, bead blasting, or anodizing can be applied.

The high precision achieved during machining minimizes the need for secondary processes, speeding up production while maintaining quality.

Conclusion: Precision 4-axis CNC machining delivers unparalleled accuracy, efficiency, and reliability, leading to higher-quality products suitable for even the most demanding applications.

Conclusion: Precision 4-axis CNC machining can handle metals, plastics, and composites, making it suitable for a wide array of industries, from aerospace to medical devices. The material choice should align with the design, performance, and cost requirements of the specific application.

4-axis CNC machining is an excellent choice for high-volume production due to its ability to combine speed, precision, and efficiency while maintaining consistent quality. Here’s why it stands out:

Conclusion: Choosing 4-axis CNC machining for high-volume production ensures efficient, accurate, and cost-effective manufacturing, ideal for industries requiring precision and scalability without compromising quality.

4-axis CNC machining ensures complex part geometries through its advanced multi-axis capabilities, allowing intricate and precise manufacturing that would be challenging or impossible with traditional methods. Here’s how it works:

By combining rotational movement with linear tool paths, 4-axis CNC machining offers unmatched flexibility and precision for creating complex part geometries. It reduces errors, improves efficiency, and meets the demands of modern industries requiring intricate designs.

4-axis CNC machining outperforms manual processes in accuracy, speed, and efficiency. Its ability to handle complex designs, automate workflows, and deliver consistent results makes it the superior choice for modern manufacturing.

Impressed by the fast delivery and top-quality CNC parts! Your team's efficiency and personalized service were outstanding. Excited for future collaborations!