Navigating the World of Advanced Manufacturing: Your Essential Guide to 3D Printing Allies

Additive manufacturing, often referred to as 3D printing, is fundamentally reshaping the product development and manufacturing landscape. More than just a buzzword, 3D printing represents a paradigm shift that enables unprecedented design freedom and dramatically accelerates the process from concept to reality. For engineers, designers and innovators looking to harness this power, especially for complex metal parts, finding the right partner is critical. This is where expertise, such as that offered by GreatLight, becomes your indispensable ally.

Beyond PLA: Uncovering the power of metal additive manufacturing

While desktop FDM printers using plastics like PLA dominate the hobbyist scene, the cutting edge for industrial applications lies in metal 3D printing. This advanced technology enables the manufacture of complex, high-strength parts for the aerospace, automotive, medical and energy sectors. At its core, metal 3D printing uses precise energy sources, such as lasers or electron beams, to build components layer by layer from powdered alloys.

GreatLight is at the pinnacle of this technology, utilizing Selective Laser Melting (SLM). SLM involves carefully spreading thin layers of fine metal powder onto a build platform. A high-powered laser beam then selectively scans the part cross-section defined by the digital CAD model, completely melting and fusing the metal particles together. The platform is lowered, a new layer of powder is applied, and the process is repeated until the entire part is formed. This approach provides superior resolution and material properties that approach and sometimes exceed traditional forged materials.

Why metal 3D printing dominates rapid prototyping:

- Uncompromising sophistication: Forging complex geometries – internal channels, lightweight lattice structures, organic shapes – would be impossible or expensive using subtractive methods such as CNC machining. This promotes real design innovation.

- Accelerate development cycles: Dramatically shorten delivery times. Design iterations can be printed quickly, accelerating testing, validation and improvement compared to traditional molding and tooling processes.

- Merge components: Integrate multiple components into an optimized 3D printed part. This reduces assembly time, minimizes potential points of failure, and generally improves overall performance.

- Material properties: Use high-performance metals such as titanium alloys (Ti6Al4V), nickel-based superalloys (Inconel), stainless steel (316L, 17-4PH), aluminum alloys and specialty tool steels – to achieve the strength and thermal properties necessary for demanding applications.

- Cost-effective for small batches: Eliminate tooling costs. Metal 3D printing excels at producing functional prototypes, custom parts, or low-volume production where traditional manufacturing methods are not economically feasible.

Your GreatLight Journey: From CAD to Finished Product

Working with a professional rapid prototyping manufacturer like GreatLight can seamlessly transform potential into reality:

- Design consultation: It starts with your vision. Our engineering team works with you to provide Design for Additive Manufacturing (DfAM) expertise. We optimize your model for printability, structural integrity, support structure and minimal post-processing.

- Material selection: Whether you need biocompatible titanium for medical implants, heat-resistant Inconel for aerospace or strong tool steel, we can provide customization and expert guidance on the best alloys.

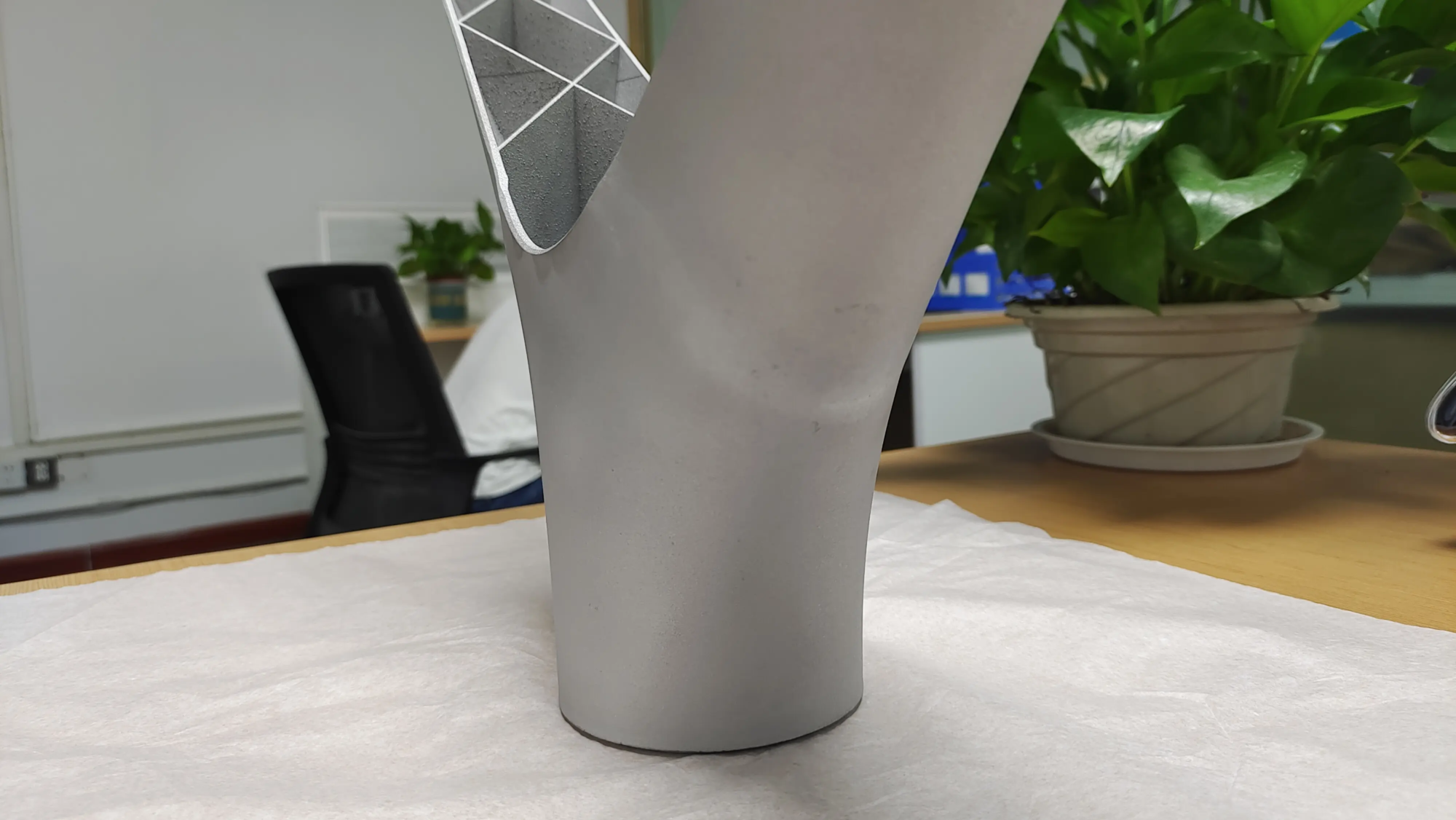

- Precision SLM printing: Using our line of advanced SLM machines, your carefully prepared designs are transformed layer by layer into dense, high-fidelity metal parts with outstanding dimensional accuracy and material integrity.

- Comprehensive post-processing: Raw 3D printed parts require finishing. GreatLight offers a complete set of One-stop post-processing serviceinclude:

- Support Removal: Carefully remove the printed support structure.

- Heat Treatment: Stress relieving, annealing, solution treating or aging for optimal material properties.

- Surface treatment: machining, polishing, sandblasting, grinding.

- CNC Machining: Used to achieve critical tight tolerance features.

- Nondestructive Testing (NDT): Inspection to ensure internal and external integrity.

- Quality Assurance and Delivery: Strict quality checks are carried out throughout the entire process. High-precision finished parts are then carefully packaged and delivered to ensure deadlines are met.

GreatLight: More than a manufacturer, your strategic ally

Choosing GreatLight means working with China’s leader in metal rapid prototyping solutions:

- Sustainable land management expertise: Our advanced SLM printing technology and deep process knowledge ensure high-quality, reliable results.

- Problem solver: We specialize in solving complex metal prototyping challenges and provide expert guidance every step of the way.

- One-stop excellence: Eliminate coordination hassles. We handle everything from material selection and printing to final finishing touches.

- Customization and speed: Most materials can be quickly customized and machined to meet specific project requirements without sacrificing quality.

- Cost-competitive premium quality: Leverage our efficiency and scale to deliver exceptional value – delivering accurate rapid prototyping parts at the best prices without compromising performance or reliability.

- Commitment to excellence: As one of the most important rapid prototyping manufacturing companies in China, we adhere to strict standards to ensure professionalism, accuracy and customer satisfaction.

in conclusion

Metal 3D printing is more than just a tool; It is the gateway to innovation and accelerated product development. However, successfully navigating its complexity requires a partner that combines cutting-edge SLM technology with deep engineering expertise and a commitment to end-to-end solutions. GreatLight embodies this ideal. From overcoming complex design challenges to delivering impeccable finished precision parts quickly and cost-effectively, we are your trusted ally. By choosing GreatLight, you can unleash the full potential of metal additive manufacturing and confidently transform your visionary designs into robust, high-performance realities.

Frequently Asked Questions (FAQ)

Question 1: What are the advantages of metal 3D printing (especially SLM) over prototype CNC machining?

A1: While CNC machining remains critical, SLM excels at handling extreme complexity (internal channels, lattice), integrating components, eliminating expensive tooling, enabling faster iterations on complex designs, and achieving geometries that cannot be milled. It is highly complementary to CNC, which is often used to post-process SLM parts to achieve tighter tolerances for specific features.

Q2: What metal materials can Honglaite usually print on, and can you handle special requirements?

A2: We usually process titanium alloy (Ti6Al4V), stainless steel (316L, 17-4PH), aluminum alloy (AlSi10Mg), nickel alloy (Inconel 625, 718) and tool steel. Crucially, Most materials can be customized Upon request. Please contact our team to discuss your specific alloy requirements.

Q3: How does Honglait ensure the quality and strength of 3D printed metal parts?

A3: Quality is crucial. We apply strict process control to our advanced SLM machines, perform meticulous parameter optimization, and utilize strategic heat treatments (stress relief, annealing, hot isostatic pressing) to achieve target material properties. Our one-stop service includes applicable NDT (such as X-ray inspection) and dimensional inspection. We can also provide material test reports.

Q4: What is "One-stop post-processing" Included in GreatLight?

A4: Our comprehensive post-processing ensures parts are ready for use. This includes critical steps such as support removal, stress relief, solution heat treatment/aging (as needed), surface finishing (grinding, machining, polishing, sandblasting) and final CNC machining for critical features or tolerances. We manage the entire finishing workflow in-house.

Q5: How fast "quickly" Using GreatLight for prototyping, especially metal parts?

A5: While complex metal parts inherently require more time than plastic parts, our focus is on maximizing speed without compromising. We achieve this through optimized printing parameters, efficient scheduling of advanced SLM machines, concurrent engineering during the design phase, and integrated post-processing workflows. Delivery times vary based on part complexity and size, but we will prioritize Quick processing and clear communication about turnaround expectations.

Q6: Why consider a rapid prototyping partner from China like GreatLight?

A6: Ferrite combines the significant advantages of China’s advanced manufacturing infrastructure and cost efficiencies with world-class SLM technology and deep engineering expertise (especially metal additive manufacturing). We provide globally competitive Best pricingfast turnaround times, high quality to international standards, seamless one-stop service and dedicated engineering support – a truly comprehensive solution for demanding prototyping needs.