Bringing Scotland to your shelves: The ultimate guide to 3D printing Highland cows (and why expertise matters)

With their shaggy coat, impressive horns and soulful eyes, the majestic Highland cattle are an iconic symbol of the Scottish Highlands. Their unique appearance also makes them a very popular and valuable subject for 3D printing enthusiasts and professionals. Whether you’re an artist creating unique sculptures, a hobbyist adding whimsy to your desk, or a business prototyping new products featuring this beloved breed, mastering 3D printing Highland cattle requires careful consideration.

This guide delves into the process, not just focusing on "how" It also highlights why expertise is often the key to achieving truly stunning results that capture the intricate detail and essence of these magnificent animals.

Why Highland Dairy Challenges and Joys: Anatomy of a Print

The unique characteristics of Highland cattle pose specific challenges for 3D printing:

- Complex fur texture: Capturing the shaggy, layered and often uneven texture of long hair is complex using traditional modeling and slicing software.

- Carved corners: Large, wide horns require strong support and careful orientation during the printing process to prevent sagging, warping, or breaking. Their smooth curves require high-resolution printing.

- Unique facial details: Achieving soulful eyes, moist noses, and crisp muzzle contours requires fine detail resolution and a smooth surface finish.

- Posture and Anatomy: Realistic posture, proportions and musculature have a strong impact on the cow’s personality and require accurate modeling.

Successfully meeting these challenges results in incredibly satisfying print results that showcase the power and artistry of additive manufacturing.

Step-by-Step Guide: From File to Finished Hyland Gugu

-

Get the model:

- Find STL: Many talented 3D artists have created models of Highland cattle suitable for printing. Explore repositories like Cults3D, MyMiniFactory or Thingiverse. Look for models with clear indications of print difficulty, optimized topology (clean geometry), and reviews detailing successful prints. Please note the artist’s notes regarding recommended directions and supports.

- Customized design: For unique applications, such as a product prototype containing a cow statue, custom modeling by an experienced CAD designer is critical. This ensures that the model is well-structured, suitable for printing and meets specific design requirements.

-

Choose the right material:

- People’s Liberation Army: Easy to print, easy to access, and affordable. Best suited for simpler models, decorative pieces where a super smooth surface is not important, or prototypes where form is important. May lack the realism needed for fine fur detail.

- Polyethylene glycol: Stronger and more durable than PLA, and not easily deformed. A good balance of detail and toughness. More suitable for models that are handled occasionally.

- Resin (SLA/DLP/MJF): The undisputed king of capturing intricate details. Layer lines disappear, fur texture micro-details shine, and horn smoothness is achieved. Perfect for miniature sculptures or detailed display pieces. Requires resin handling and post-processing (cleaning, curing).

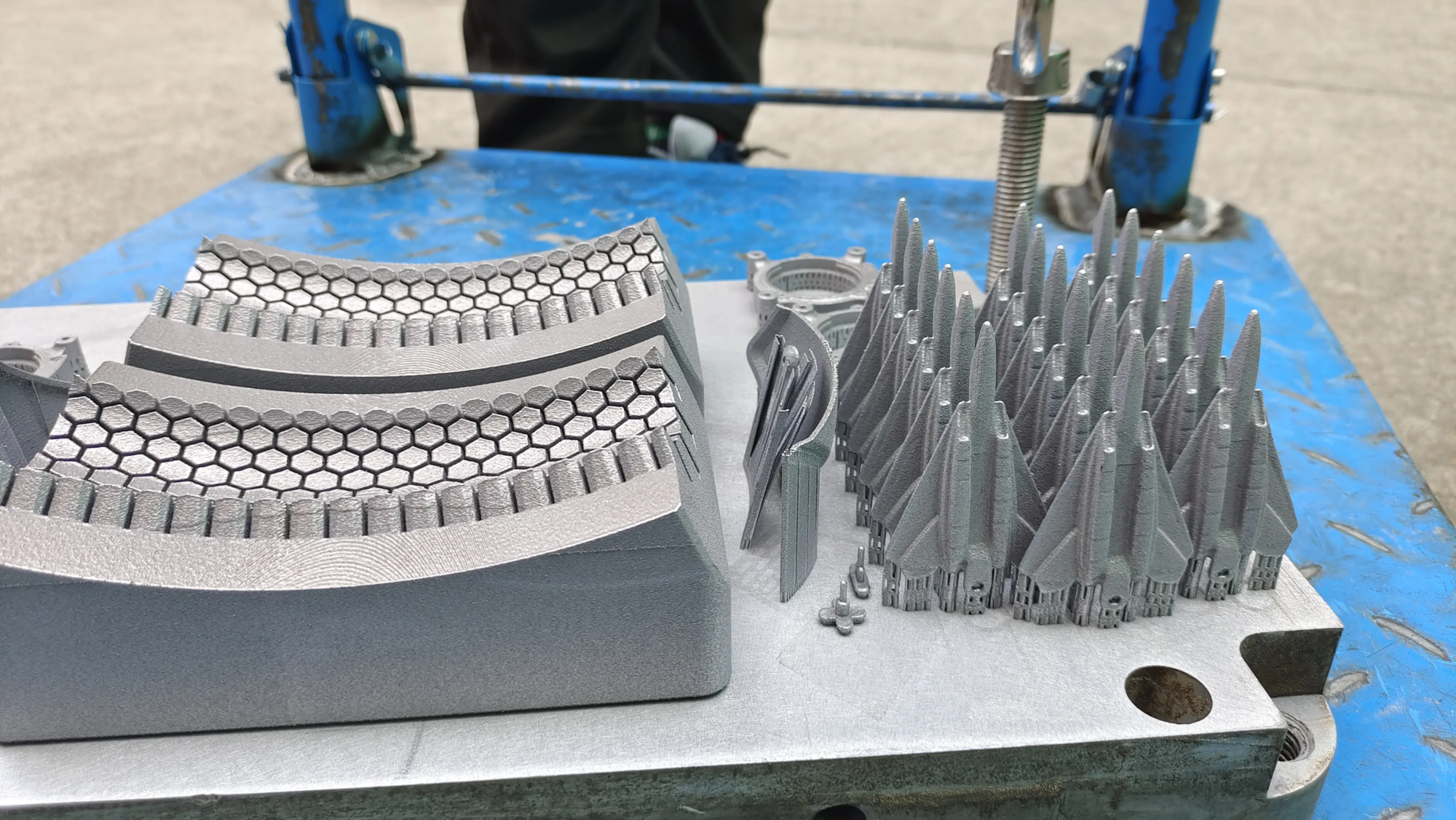

- Metals (via SLM/SLS): Crucial for highly durable prototypes, functional parts, or advanced artwork that requires the feel and strength of metal (such as sculptural versions). Allows the creation of true bronze effect horns or alternative metallic finishes. This is where professional services like GreatLight come in handy. Materials such as stainless steel, titanium or aluminum alloys open up incredible possibilities.

-

Strategic slicing:

- direction: Crucial! Position the model to minimize support on visible surfaces such as the face and lower abdomen. Horns often need to be carefully balanced – printing the horn tip down may require dense support, but provides a pristine underside; printing tip up may result in tip deformation or poorer tip quality, but minimizes support scarring on the main horn surface.

- support: Using a tree support makes removal easier and minimizes scarring, especially underneath complex areas of fur. Be sure to provide adequate support to the corners and any overhangs created by the furry coating.

- Floor height: Lower layer heights (e.g. 0.1 mm or lower for FDM, default resin resolution) can greatly improve fur texture, corner detail, and facial features.

- Print speed: Slower speeds significantly improve surface quality, which is critical for complex textures and avoiding artifacts on corners.

- Filling/graded filling: Use enough infill (15-25%+) to ensure stability, especially for taller prints. Graded infill (more dense near stress points such as the base of the speaker) saves material while ensuring strength.

-

Print execution:

- Machine calibration: Carefully level your bed. Make sure the belt is tensioned correctly and calibrate the extrusion.

- environment: Control airflow (for FDM) and temperature/humidity (for resin).

- monitor: Check the printing regularly, especially during the critical horn printing stage.

- Post-Processing: The Art of Finishing (Make Your Cow Shine):

- Support removal: Patience is the key! Use a flat end mill, hobby knife, or specialized support removal tool. Sand carefully around the support attachment points.

- Polishing: Start with coarse grinding (to remove major imperfections/support nubs) and work your way through to finer grit. Essential for smoothing the layer lines on the corners and achieving a realistic hidden surface underneath the fur texture. Essential for FDM printing. Resin prints usually require less vigorous sanding.

- Clean (resin): Thorough IPA cleaning followed by proper curing according to resin specifications.

- Surface treatment (metal): Professional post-processing for stunning realism:

- Metal: Vibration tumbling (for softening/smoothing), precision CNC machining (for critical surfaces), polishing (mirror corners!), professional sandblasting (various textures), engraving, electroplating (gold/silver corners), spray painting (acrylic/oil rust), powder coating.

- GreatLight Pro Tips: Anodized aluminum cows can create incredible horn effects that mimic natural horn coloring layers.

- painting: For non-metallic prints:

- Primer: Use a filler primer to further smooth the FDM printed layer lines and provide a good base.

- Primer: Spray paint provides smooth, even coverage of major coat colors (red, brown, black, yellow).

- Detailed description: Using acrylics to render intricate fur textured highlights, unique muzzle "Oreo" Bands, eyes (gloss varnish adds pizzazz!), hooves and horns. Dry brushing works perfectly to capture the texture of layered fur. Painting metal prints requires specialized primers and coatings designed specifically for metal bonding.

- assembly: For multi-part printing (head/corners/body), please use a strong adhesive suitable for the material (superglue/CA glue, epoxy resin, special plastic glue).

Conclusion: Beyond Printing Farm Gate

3D printing the Highland Cow was a journey that blended technical skills with artistic vision. Success depends on understanding the complexity of the model, selecting appropriate materials and printing techniques, meticulous slicing, careful printing, and skillful post-processing.

While hobbyists can achieve wonderful results using FDM or resin decorative pieces, achieving museum-quality realism, unparalleled durability using metal, or superior functional prototyping requires specialized equipment and expertise.

This is where working with a specialist rapid prototyping manufacturer like GreatLight provides transformative advantages. Have cutting edge SLM 3D printerin-depth advanced knowledge production technologyand comprehensive One-stop post-processing serviceGreatLight specializes in solving complex metal prototyping challenges. Whether you need stainless steel miniature art with a hyper-realistic finish, a durable titanium horn prototype, or a custom alloy solution for a unique project, GreatLight has the capability and craftsmanship.

as One of China’s leading rapid prototyping companiesglow offer Excellent customization, Quick turnaroundand exceptional value Competitive price. Don’t compromise when it comes to turning your Highlad cow vision into reality – harness the true potential of metal 3D printing. Ready to realize your vision in stunning detail? Customize your precision Highland Cow prototypes and metal artwork with GreatLight today.

FAQ

-

Q: Can I really 3D print a metal Highland Cow?

one: Absolutely! Using techniques such as selective laser melting (SLM), binder jet printing or metal FFF combined with sintering/debinding (material jetting is also possible!), metal 3D printing is ideal for durable sculptures, high-quality artwork or functional prototype components depicting highland cows. Companies like GreatLight specialize in producing high-quality, complex metal parts. -

Q: What are the best printing materials for realistic fur textures?

one: Resins (SLA/DLP) often achieve the finest surface details required to effectively replicate fur without extensive post-processing. High detail FDM filaments such as PLA/PLA+ can capture texture reasonably well with fine nozzles, low layer heights, and careful slicing, but typically require extensive sanding/texturing post-processing to compete with resin. Multi-nozzle Fusion PA12 delivers excellent detail and a slightly grainy texture that mechanically mimics hair very well. -

Q: How to avoid breaking horns?

one: direction: If possible, print the horn vertically, with the stand extending completely to the bed. Consider printing tilted upward for stability (needs careful support/sanding) or tilted for optimal bottom horn surface quality (requires support for top horn curvature).

Material: Stronger materials such as PETG, nylon, resin or metal will naturally reduce the risk of breakage. PLA horns, especially the thin tips, are fragile.

support: Use adequate support density/contact points for the overhang below the speaker. Implement lower temperature/high cooling to prevent FDM sagging.

deal with: Use extreme caution during support removal and post-processing. Use the body to handle the marks, not the horns. -

Q: How long does it take to print a Highland Cow?

one: This makes a huge difference:- size: Small micro (a few centimeters): FDM 1-4 hours/resin <2 hours.

- Medium decorative (10-20 cm): 6-24 hours FDM / 3-10 hours resin.

- Large Sculptures (>20cm): Multi-Day FDM/12+ Hour Resin Resin/Metal SLA/SLM printing may also take 24+ hours depending on size/quality.

- solve: Lower layer height/resolution will significantly increase print time.

- Metal SLM: Due to the layer-by-layer nature of fusion, high-resolution complex metal prints can take hours or even days to produce for larger works of art.

- Q: Why choose a professional prototyping service like GreatLight to create something like Highland Cow?

one: A professional prototyping partner offers significant advantages, especially for critical applications:- Expertise: Gain insights into material properties, design optimization (DfAM), complex slicing, and advanced print troubleshooting.

- Advanced machines: Access high-precision industrial SLM, SLS, MJ