Unlocking speed in additive manufacturing: AD5X 3D printer revolution

In the fast-paced world of manufacturing and product development, time is the ultimate currency. Delay means missed opportunities, budget overspending and stifling innovation. This is where the AD5X 3D printer comes into play as a transformation solution. Designed for industrial-grade efficiency and precision, the AD5X redefines rapid prototyping by providing very fast print without compromising quality or complexity. At Greatlight, we position ourselves as a leader in the rapid manufacturing of landscapes by leveraging the power of AD5X (such as AD5X) advanced additive technology to solve key challenges in metal parts prototyping and production.

Why speed matters in modern prototypes

Traditional manufacturing methods such as CNC machining or casting usually involve long-term tools, set-up and processing lead times. These delays can be harmful for businesses that develop new products, iteratively design or meet urgent production needs. Prototype speed enabled:

- Accelerate product cycle: Test iterations in days rather than weeks.

- Shorten market time: Take advantage of market opportunities faster.

- Cost Efficiency: Minimize expensive machine downtime and labor.

- Enhanced creativity: Promote rapid experimentation and improved cultivation.

The AD5X 3D printer is clearly designed to meet the speed demands of strict demands for professional applications.

AD5X: Outstanding Outstanding Combustion Output

So, what makes the AD5X an outstanding candidate for fast printing? Its performance is derived from a combination of cutting-edge hardware, intelligent software and process optimization:

- Advanced heating and cooling systems: The AD5X has sophisticated thermal management that ensures rapid and even heating of the build materials with optimal processing temperatures and equally effective cooling cycles. This reduces the key "cool down" Waiting time common in metal printing greatly reduces the overall work duration.

- High-precision laser technology: The AD5X uses a powerful and ultra-fast laser system to achieve exceptionally high scanning speeds and accuracy. This allows it to melt and fuse layers of material (especially metal powders using SLM principles) faster than standard industrial printers, while maintaining resolution and structural integrity.

- Optimized motion control and mechanics: The construction of a rigid frame, a high voltage motor and an accurate linear system enables the printer head (or laser/Galvo system) to move at unprecedented speeds without vibration or inaccuracy. Each sport is calculated for minimum travel and maximum efficiency.

- Smart slicing software: Proprietary slicing algorithms go beyond the generation of basic layers. They optimized the tool route for speed – minimizing laser on/off time, reducing non-press action, and strategically managing energy inputs to prevent distortion – all of which ensures model integrity.

- Material versatility and compatibility: The AD5X is compatible with a wide range of high-performance engineering materials including a wide range of tool steels, titanium alloys, nickel superalloys and aluminum alloys for rapid processing. The flexibility of this material allows Greatlame to select the ideal metal powder for speed and functional requirements.

- High flexibility of layer: While maintaining high resolution when needed, the AD5X can often increase layer heights for specific geometries whose surface effect is less critical. This directly helps faster build times without sacrificing the accuracy of dimensions.

Overcoming Speed: Greglight’s Overall AD5X Advantages

Selecting AD5X with Greatlight is more than just raw print speeds; it’s about accessing a comprehensive professional service ecosystem:

- End-to-end post-processing: The speed does not end on the printer. Greatlight offers integrated post-processing services – including pressure relief, heat treatment, precision CNC machining, EDM, polishing, surface treatment (bead blasting, coating) and meticulous inspection (CMM, CT, CT scan). this "One-stop" Approach ensures functional, available parts without supply chain delay.

- Expert-driven solutions: Our team leverages deep expertise in additive manufacturing parameters, materials science and DFAM (designs for additive manufacturing) to maximize the functionality of the AD5X. We recommend orientation, support structural and design modifications to enhance speed, strength and manufacturability.

- Dedicated to quality and precision: Speed is meaningless and has no quality. The AD5X always produces parts with excellent mechanical properties, dimensional accuracy and repeatability, meeting strict industry standards (ISO, AS9100).

- Quick customization: Do special materials or post-treatment be needed? Gremight excels in fast customization solutions. Our advanced infrastructure can effectively customize material mixtures and complete requirements to fully meet the technical needs of your project.

- Competitive cost efficiency: By greatly reducing printing time and eliminating the need for tools, combining Greatlight’s efficient high-volume functionality and competitive pricing model, the AD5X offers excellent value to make professional-grade fast prototypes accessible.

AD5X accelerated applications

In the scenario, the AD5X excels at the fast turnover of robust high-precision metal parts:

- Functional prototype: Testing complex metal components in real-world conditions is faster than ever before.

- Fixtures, fixtures and tools: Production of customized manufacturing auxiliary tools on demand improves production line agility.

- End-use parts: For small-scale production operations (especially aerospace carriers, medical devices, automotive components).

- Spare parts and repairs: Rapidly produce outdated or difficult-to-power metal parts to minimize downtime on equipment.

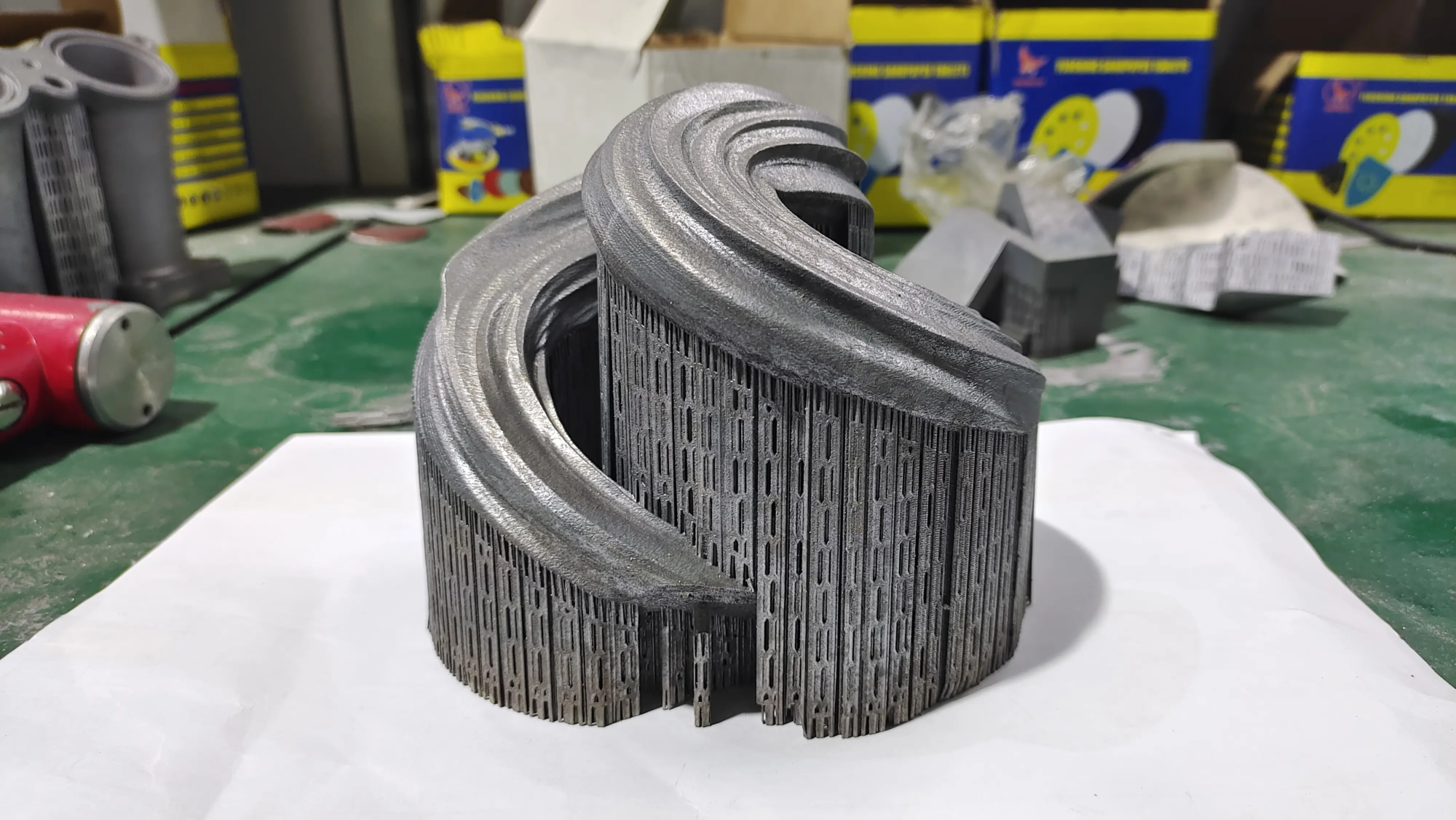

- Innovative design concept: Rapidly iterate complex lattice structures, topologically optimized parts or consolidation components that are traditionally impossible to make.

Conclusion: The future of rapid prototyping is fast, here

The AD5X 3D printer represents a major leap in the industrialization of additive manufacturing. It solves the core pain points of modern engineering and manufacturing by determining unprecedented printing speeds while maintaining the high standards of quality, accuracy and material versatility required for professional applications. AD5X is a powerful driver for enterprises seeking faster innovation, responsiveness to market demand and simplifying development costs.

Greglight is at the forefront of this revolution. As a professional rapid prototyping manufacturer equipped with cutting-edge technologies such as the AD5X and gaining comprehensive post-processing expertise and a commitment to customer-centric customization, we offer tangible value. We don’t just print parts; we provide accelerated solutions to complex manufacturing challenges.

Unlock the potential for speed for your next project. Experience the great differences and discover why we have always ranked among China’s premier rapid prototype partners. Contact us today for a custom quote about your high-precision, quick-torque metal parts.

Frequently Asked Questions about AD5X 3D Printers and Services (FAQs)

Q1: Just How many Is the AD5X faster than standard industrial metal 3D printers?

A: While the exact speed increase depends on the part’s geometry, material and required resolution, the AD5X usually achieves speed 20% to 50% fast Comparable industrial SLM/DMLS printers. Optimization with software and thermal management can significantly reduce cycle time.

Q2: Can AD5X also print non-metallic materials?

Answer: AD5X is mainly aimed at Metal powder bed fusionspecially used selective laser melting (SLM) technology. Greglight uses AD5X for high-speed metal prototyping and production. For polymer parts that require speed, we use complementary industrial-grade technologies.

Question 3: Will speed damage the strength or mass of printed parts?

one: Absolutely not. The AD5X achieves its speed through advanced engineering of laser control, thermodynamics and motion systems, rather than skipping basic process steps. Printed parts are subject to strict quality control, usually meeting or exceeding the required material specifications and density. Post-treatment (such as heat treatment) further enhances mechanical properties.

Question 4: What post-processing services are provided specifically for AD5X printing parts?

A: We provide a complete suite:

- clean: Powder removal (manual and automatic).

- Heat treatment: Pressure relief, annealing, hip joints (hot etc. are still).

- Support removal: Precise cutting and grinding.

- Processing: CNC milling/turning to achieve critical tolerances and mating surfaces.

- Surface finish: Bead/sand blast, polish, grind, coating (e.g. anodizing).

- examine: Dimensional inspection (CMM), non-destructive testing (X-ray CT), material testing.

Q5: How flexible is the Greatlight of the material? Can I do custom alloy treatment?

one: Highly flexible. Our core strength lies in customization. We regularly process standard materials (Ti6al4v, Alsi10mg, stainless steel, eg 316L/17-4PH, Inconel 718/625, tool steel). Crucially, we have the expertise and infrastructure to work with our clients Custom material parameters or process development of specific alloy mixtures, but comply with feasibility and quantity requirements.

Question 6: Why choose Greatlime over other rapid prototype services in China?

Answer: We passed:

- Technical Leadership: Investment in high-speed printers like the AD5X.

- Vertical integration: From design consultation and printing to complete post-processing under one roof.

- Deep expertise: Years of professional experience in metal AM and precision machining.

- Commitment to quality: Strict QA/QC protocols comply with international standards.

- Speed and Agility: Focused on workflow optimization, which can be used for fast custom turnaround without compromising quality.

- Competitive value: High-end features with global competitive advantages.