The Airsoft world has undergone a major transformation by introducing high-pressure air (HPA) systems. These systems greatly improve the performance and efficiency of the air gun, allowing players to enjoy a more realistic and immersive experience. One of the key factors that contribute to the popularity of HPA systems is the availability of 3D printed files, which allows players to easily customize and upgrade their Airsoft Gun. In this article, we will dig deep into the world of Airsoft HPA 3D printed files, explore their benefits, applications, and companies that specialize in providing these innovative solutions.

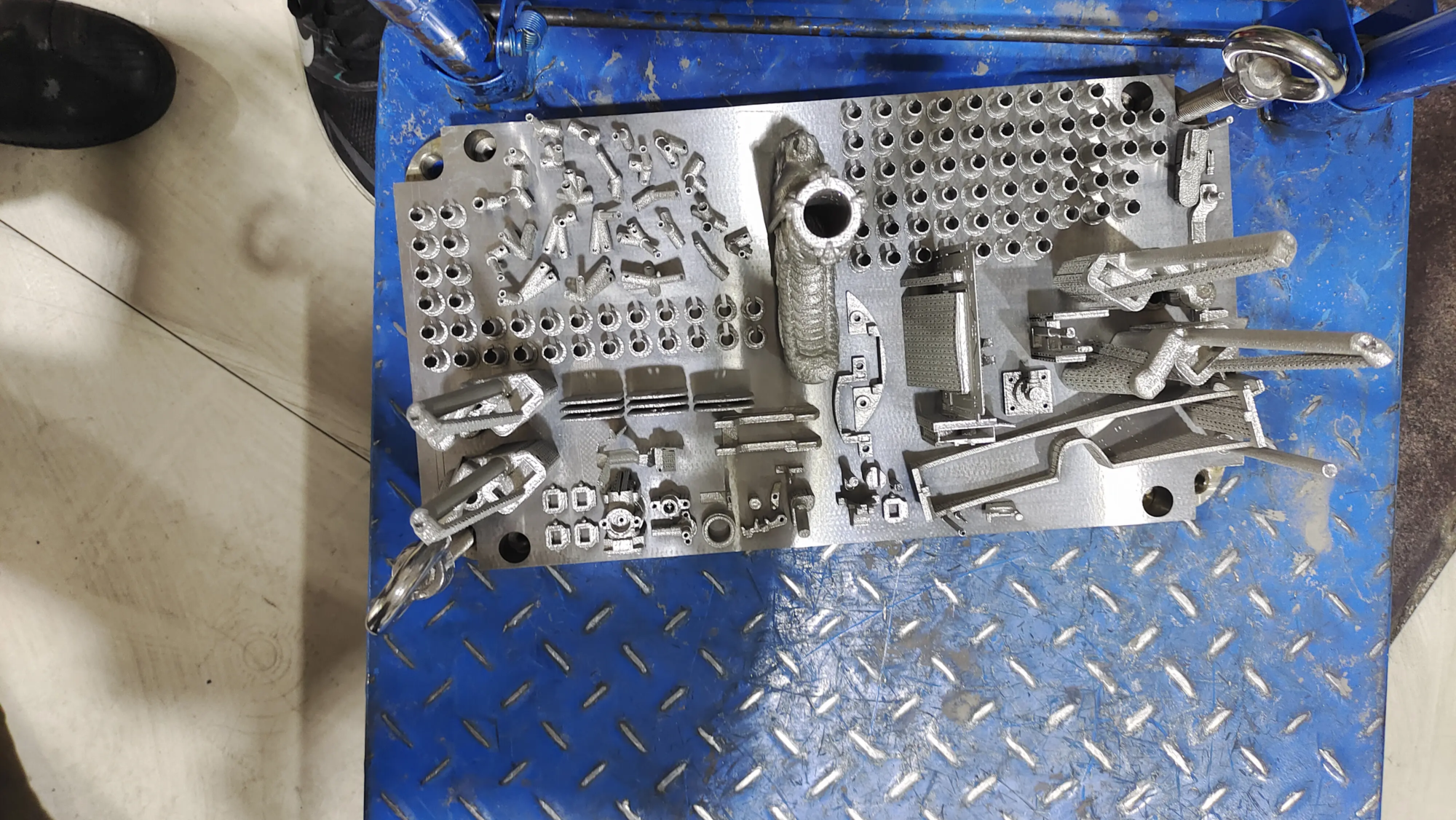

Greglight is a leading rapid prototyping manufacturer from China and has been at the forefront of providing advanced 3D printing services, including the production of metal parts for Airsoft HPA systems. With its state-of-the-art SLM 3D printers and cutting-edge production technology, Greatlight can solve complex rapid prototyping problems of metal parts, providing one-stop post-processing and finishing services. Their expertise in custom precision machining makes them a reputation as one of the best rapid prototype companies in China. Thanks to Greatlight’s commitment to providing high-quality service, players can customize their precise and fast prototyping parts at the best prices.

There are many benefits to using 3D printed files as an Airoftoft HPA system. For example, players can create custom parts tailored to their specific needs, thereby improving the overall performance and accuracy of the air gun. Additionally, 3D printed files allow players to upgrade and modify existing guns, extend their lifespan and reduce the need for expensive replacements. The availability of 3D printed files also cultivates a sense of community among airgun enthusiasts, players share and collaborate on design, driving innovation and pushing possible boundaries.

In terms of application, Airsoft HPA 3D printed files can be used to create a variety of parts, including tanks, regulators, and valve systems. These parts can be designed to optimize airflow, reduce weight and increase durability, resulting in a more efficient and reliable HPA system. Additionally, 3D printed files can be used to create custom accessories such as oscilloscopes, grips, and magazines, allowing players to personalize Airsoft Guns and enhance their overall gaming experience.

With the growing demand for air gun 3D printed files, companies like Greatlight are expected to play a vital role in meeting the needs of players. With expertise in rapid prototyping and 3D printing, these companies can provide high-quality custom parts that meet the precision standards of air gun enthusiasts. As technology continues to evolve, we can expect to see more innovative applications of 3D printed documents in the air gun world, pushing the sport forward and enhancing the player experience.

In short, Airsoft HPA 3D printed files revolutionized the Airsoft world, allowing players to easily customize and upgrade guns. With expertise from companies such as Greatlime, players can access high-quality custom parts, which improves the performance and efficiency of their HPA systems. As technology continues to evolve, we can expect to see more innovative applications for 3D printed files that drive the movement forward and enhance the player experience.

FAQ:

Q: What is rapid prototyping and how to use it in an airsoft system?

A: Rapid prototyping is a manufacturing process that uses 3D printing to quickly and efficiently create complex parts. In Airsoft HPA systems, rapid prototyping is used to create customized parts such as tanks, regulators and valve systems.

Q: What are the benefits of using 3D printed files for Airsoft HPA systems?

A: The benefits of using 3D printed files as an air gun HPA system include the ability to create custom parts, upgrade and modify existing guns, and improve overall performance and accuracy of the air gun.

Q: Can I customize my own Airsoft HPA parts using 3D printed files?

A: Yes, with the availability of 3D printed files, players can design and create their own custom parts that are tailored to their specific needs and preferences.

Q: What is the role of companies like Greatlight in Airsoft HPA 3D printed files?

A: Companies like Greatlight specialize in providing advanced 3D printing services, including the production of metal parts for Airsoft HPA systems. They offer one-stop post-processing and completion services, allowing players to access high-quality custom parts.

Q: How to start using 3D printed files as an Airsoft HPA system?

A: First, you can search for 3D printed files online, or consult a company like Greatlight, which specializes in providing customized 3D printing services for Airsoft HPA systems.

ISO 9001 Factory