3D printing has become a revolutionary technology when implementing complex designs and bringing innovative ideas to life. In various types of 3D printing, the ability of selective laser melting (SLM) stands out from the crowd to produce metal parts with unprecedented precision and detail. Greglight is a leading rapid prototyping manufacturer based in China, specializing in using this technology to solve the prototype challenges of metal parts. With its state-of-the-art SLM 3D printers and advanced production technology, Greglight provides a one-stop solution for all prototype needs, including post-processing and completion services.

The versatility of Greatlight services extends to customization of materials, allowing the rapid and efficient handling of various metals. This capability is particularly beneficial for industries requiring customized precision processing, where the ability to prototypify can quickly significantly accelerate the product development cycle. As one of the best rapid prototype companies in China, Greatlight has a good location to meet the growing demand for customized precise parts, serving at competitive prices without compromising quality.

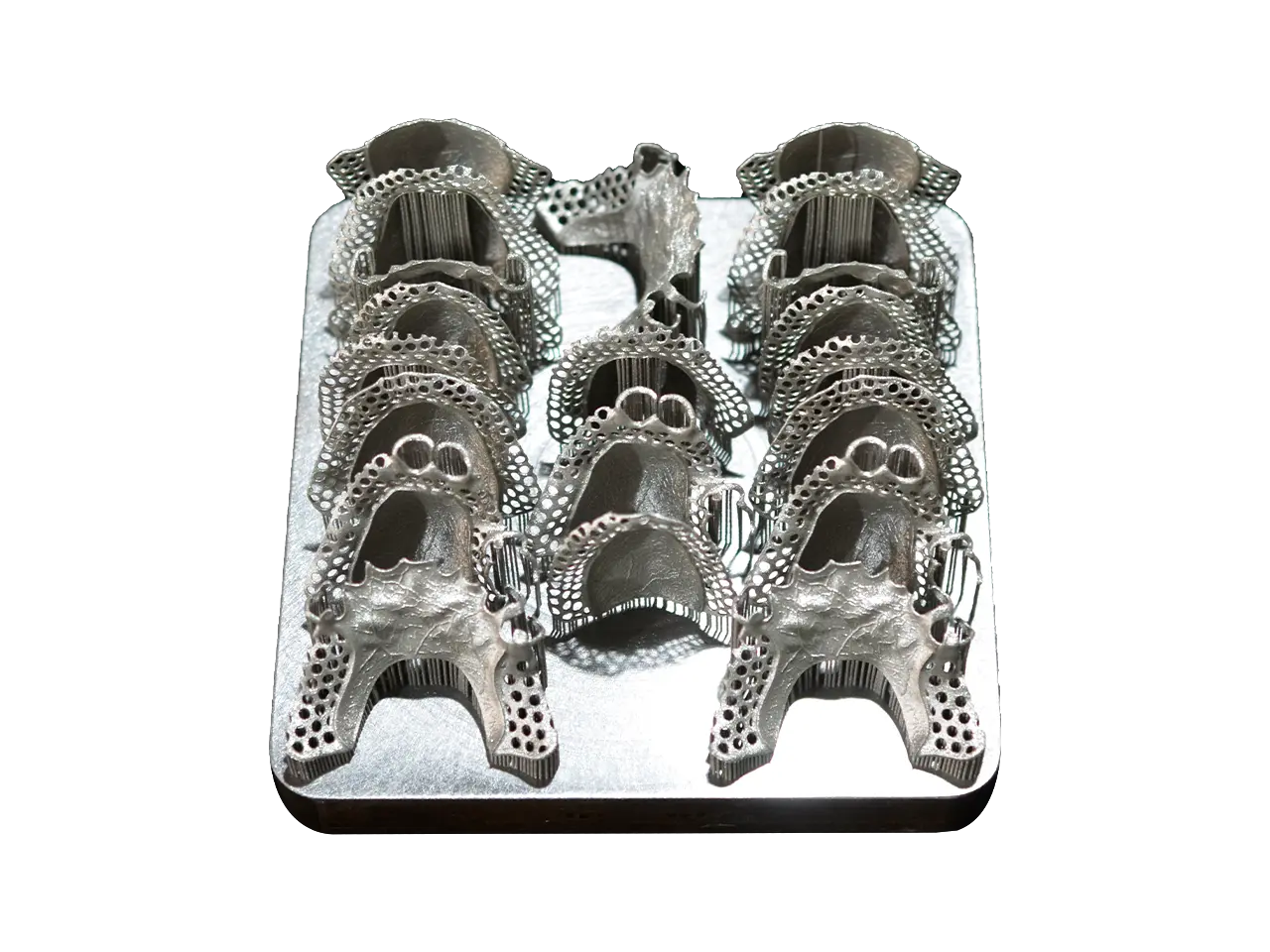

From a technical point of view, the SLM process involves selective melting of the metal powder through a layer of high power laser to construct the required portion. This approach allows the creation of parts with complex geometric shapes and structures that traditional manufacturing techniques cannot produce. The accuracy and solutions that SLM 3D printing can achieve make it an attractive choice for industries such as aerospace, automotive and medical equipment, where the performance and reliability of parts are crucial.

In addition to its technical capabilities, Greatlight’s commitment to innovation and customer satisfaction makes it a leader in the field of rapid prototypes. By continuously investing in R&D, the company has been at the forefront of 3D printing technology to ensure its customers have access to the latest advancements and technologies. Furthermore, its customer-centric approach means that each project is tailored to meet the specific needs and deadlines of the client, resulting in high-quality prototypes that exceed expectations.

For businesses and individuals who want to leverage 3D printing as projects, working with professional manufacturers like Greatlight can be a game-changer. Not only does it provide access to cutting-edge technology and expertise, it also simplifies the prototyping process, saving time and resources. Whether it is the requirement of single prototypes or mass production, Greatlight’s one-stop service and fast turnaround capabilities make it an ideal partner to effectively achieve project goals.

In short, the functionality of 3D printing, especially in the field of SLM technology, is changing the way prototyping and production is done. Companies like Greatlime are within the pioneering scope of this revolution, providing a convergence of technical expertise, innovation and customer-centric services that make them valuable partners for global industries and innovators. With the continuous development of technology, the potential of 3D printing can solve complex manufacturing challenges and bring novel products to the market very broadly, and manufacturers like Greatlight are expected to play a central role in this exciting future.

FAQ

-

What is a rapid prototype?

- Rapid prototyping refers to the process of quickly creating a part or product prototype using 3D printing or other additive manufacturing techniques. This method allows for rapid testing and refinement of the design.

-

What is SLM 3D printing?

- Selective laser melting (SLM) is a 3D-printed type that uses laser melting and fusing metal powders, which then fuses them together in a layer to create parts. It is known for its precision and ability to produce parts in detail.

-

Which industries benefit from 3D printing?

- Industry sectors such as aerospace, automotive, medical equipment and consumer products benefit greatly from 3D printing because of their ability to produce complex geometric shapes, reduce material waste and accelerate product development.

-

How does Greatlight customize 3D printed materials?

- Greatlight customizes materials by quickly and efficiently handling a variety of metals. This is achieved through its advanced SLM 3D printing equipment and production technology.

- What are the advantages of working with professional 3D printing manufacturers?

- Working with professional manufacturers like Greatlight, you can access advanced technology, expertise and one-stop service including post-processing and completion. This partnership can simplify the prototyping process, save time and resources, and ensure high-quality prototypes that meet the needs of a specific project.