According to the resource database, many Chinese automotive companies, such as Byd, Great Wall Motors, Geely, Nio and Saic, applied 3D printing technology in the design of the prototype, parts production, personalized accessories And the manufacture of production tools to improve R&D efficiency to improve R&D, reduce costs and improve personalization capacities. By taking Byd as an example, 3D printing is used to quickly produce prototypes, structures and test functions, and is also used to produce personalized tools and accessories.

As the automotive industry improves performance, efficiency and personalization requirements, the choice of materials is becoming more and more important. As an important driver’s material, silver has an unequaled electrical conductivity, with a conductivity up to 6.3 × 10⁷ s / m, first ranking among all metals. Silver powder is particularly suitable for high frequency and high precision electronic devices, and its low -temperature treatment and training characteristics can avoid damaging the high temperature substrate, so it has significant advantages in processes such as that cold spraying and adhesive spraying.

Recently, Anhui Zhongti New Materials Technology Co., Ltd. (hereinafter referred to “Zhongti New materials») Announced that its intelligent independent -developed intelligent powder -developed production line has officially started production.A new leading energy vehicle companycustom made,Annual production capacity can reach 30 tonnesProducts mainly target high -end application fields such as additive manufacturing.

Zhongti New Materials has always considered technological innovation as the main driving force in the development of the company. The production line of silver powder has been put into production this time produced high quality silver powder with excellent conductivity, thermal conductivity and oxidation resistance. Additive manufacturing request for high -end application scenarios. The characteristics of specific products include:

– High purity (AG> 99.99%)

– high spherical (> 92%)

– Installation of takamatsu and tap density

– very few satellite particles and hollow powder

-Particle size range: 0-25 μm, 15-45 μm, 45-150 μm, etc.

To ensure the consistency and stability of the product, the production line is equipped with an advanced quality inspection system and performs automatic control throughout the process. This intelligent production system promotes not only industrial upgrading, but also providesFour basic advantages:

– Digital control: thanks to the MES system, we carry out the complete traceability of the process, from raw materials to finished products

– Cleanliness guarantee: independent workshop of 100,000 levels, ensuring that the product is free from impurities

– Precise control of particle size: adopts the hierarchical air flow detection technology, the particle size CV value CV value is less than 15%

– Personalized development: Support customers to personalize special specification products with particle size intervals of 0-150 μm

In fact, in addition to its application in the automotive field, the prospects for money powder are becoming wider in other industries. With the continuous development of additive manufacturing technology, the application of silver powder has gradually emerged, in particular in high -end fields such as electronics, new energies and medical devices. Silver powder has shown enormous market potential in electronic devices, conductive lines, 5G / 6G radiofrequency devices, biosa and cold spraying.

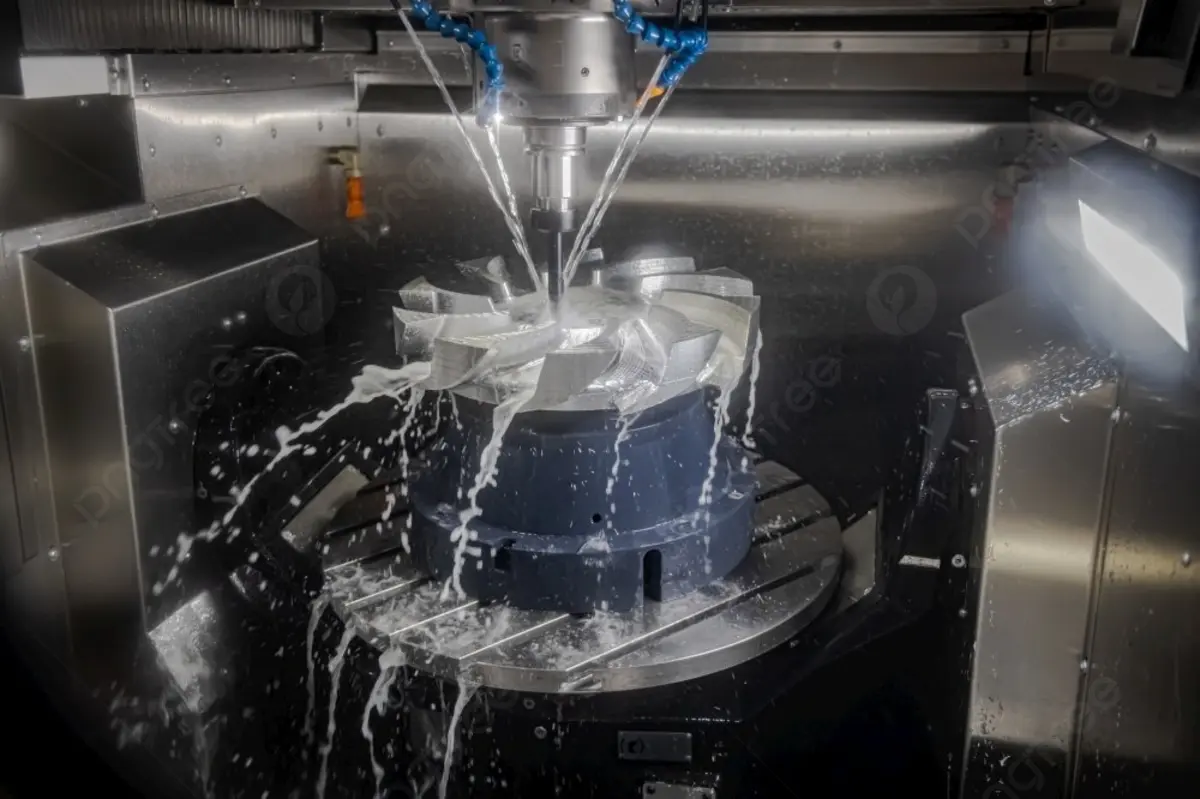

Typical additive manufacturing technology and application of silver powder

In terms of environmental protection and sustainable development, Zhongti’s new materials are also at the forefront of the industry. The production line of silver powder put into production this time adopts a number of energy saving technologies and environmentally friendly, including a closed traffic water cooling system, which effectively reduces energy consumption during the production process. At the same time, the company has also established a complete silver powder recycling system with a recycling rate of up to more than 99%, effectively reducing the cost of precious customers.

As a research focusing on research and development and industrialization of micro-à the nano-scale metal powder materials, the new Zhongti materials have permanently launched a series of high-quality metal powder products covering the Nickel -based metals, based on copper and precious, including nickel -based metals, nickel, nickel -based, based on nickel, Nickel -based, based on nickel. advanced technological fields. In the future, Zhongti’s new materials will continue to focus on the field of high -end materials, to take technological innovation as an engine, will continue to meet customer needs and try to become the main supplier Industry solutions, contributing to global scientific and technological progress and industrial upgrade.

Contact details:

Tel: +86 021 69005580

Email: survey@cnpowder.com

Official website: www.cnpcpowder.com