Beyond the Hype: Materials Science for Food Safety 3D Printing

Image: You have designed the perfect custom cookie cutter, stylish herbal feeder or unique cup comfort. The excitement of bringing it into a 3D printer is obvious. But a crucial question quickly surfaced: Can this plastic creation actually touch your food safely? In addition to attractive aesthetics and technical specifications, there is a complex world defined by materials science. The choices you make on the lamp post spool directly affect the safety and suitability of the final print for food contact. Let’s study the science behind choosing safe filaments.

Why "Food safety" Not only the filament label

It’s easy to grab a marked spool "PLA Food Safety" And think you’re covered up. Unfortunately, the reality is even more subtle. Announces a convergence of food safety in 3D printed items involving understanding the impact of materials’ chemistry and physics:

- The filament material itself: Essentially, which polymers and additives make up plastics? PLA is largely derived from corn starch, providing a biological basis. PETG is praised for its chemical resistance and durability. PP has excellent water resistance and can be widely used in food containers. Others, such as ABS, although powerful, usually contain styrene, causing concerns.

- Additives and Impurities: Filigree manufacturing involves pigments, plasticizers, stabilizers, fillers (such as wood or metal) and processing aids. Are these additives approved for food contact? Cheap filaments are more likely to include unknown or potentially harmful substances that may be immersed in food, especially under hot or acidic conditions. Find thin filaments that have been approved for food safety standards such as FDA CFR 21 or EU 10/2011 Specific application.

- Microbial Trap (Porosity): This is the elephant in the Fusion Sediment Modeling (FDM) room. Laminar lines, microscopic gaps and inherent porosity create mazes where bacteria like Salmonella or E. coli can reproduce and reproduce. This is very difficult for a standard FDM, and it is actually impossible to produce a truly non-porous surface that can be completely sterilized. A smooth surface is essential for food safety.

- Chemical leaching and migration: Can chemicals in plastics migrate into food over time? Factors that affect this include:

- temperature: Hot liquids or dishwashing greatly increases leaching potential.

- Food Type: Acid foods (ketchup, citrus juice), fat foods or alcohol can interact with plastics and extract compounds.

- Contact time: Longer contact times increase migration risk.

- Mechanical stress: Scratches or wear of the cutlery can exacerbate leaching.

- Durability and degradation: Will the materials be washed repeatedly? Will it break or degrade over time, increasing porosity or releasing particles? For example, PLA becomes fragile and may deform under relatively moderate heat. Thermal and mechanical fares for PETG and PP are better.

Navigate the filament maze for safer food contact

Given these complexities, here is the material scientific view on common filaments:

-

PLA (polylactic acid):

- advantage: Biogenic, usually considered as its pure form of security (GRA). Wide availability, easy to print. Low warping.

- shortcoming: Low heat resistance (distorted by 50-60°C). Maybe crunchy. Apparent porosity. Over time, it is prone to degradation, especially under moisture/pressure. Due to additives, few commercial quality is fully food grade. Suppose it needs to be sealed.

- Best for: Only short-term contact with cold dry foodlike a decorative cookie cutter for a brief period back Thoroughly sealed. Avoid dishwasher, hot food, and store it for a long time.

-

PETG (Glycol modified pet):

- advantage: Good chemical resistance, higher temperature resistance than PLA (softening around 70-80°C). Impact resistance. Transparency is possible. There are fewer porosities than PLA, but porosity remains a challenge. More likely to find options to get food contact.

- shortcoming: Still porous. It can absorb moisture during printing, which affects performance. It is susceptible to pressure rupture under certain chemicals. The surface can be tricky/thorny at first.

- Best for: More durability and moderate heat resistance are required compared to PLA, such as water bottles (After thoroughly sealing),tableware(no food contact surface) or for dry goods.

-

PP (polypropylene):

- advantage: It can be said to be the best Material Candidates on this list conduct food contact. Excellent chemical resistance (especially fats and acids). High heat resistance (dishwasher safety – top rack ~75°C+). Natural, flexible and tough. Widely used in food containers. Pure form migration potential is low.

- shortcoming: Printing on a standard FDM printer is very challenging. The bed has poor adhesion and a lot of warping requires high bed temperature and shell. Very low surface energy makes adhesion and sealing difficult. Porosity remains.

- Best for: Those willing to rigorously adjust advanced printers. Functional food containers, reusable storage covers, great potential for dishwasher safe items if Printing seals almost perfectly and effectively. If it is targeted at a true food grade application for prototypes, the best choice.

- Other materials (ABS, nylon, etc.): Generally speaking Not recommended. ABS usually contains styrene and is known to be harmful. Nylon absorbs a lot of moisture and is difficult to print food safe. Both require very high printing temperatures, which increase the risk of thermally degraded products unless specially certified food grade variants are used.

The key role of post-processing: sealing transactions

Material selection is just the beginning. To severely mitigate risks, effective post-processing is infeasible:

- Grinding: Smoothing surfaces reduce the depth and size of the holes. Best results with gravel (220->600+).

- Food safety sealant/resin: Basic. Applications are specially designed to fill pores and create continuous barriers for food safety coatings:

- Epoxy resin: Highly durable, high-quality chemical/waterproofing. Must be certified food safety After complete cure (For example, FDA CFR 175.300 meets the criteria). Rarely used – thick layers can be uneven or cracked. Popular Choices: Artresin (check for specific certification), Max CLR, Specialty Food Safety Epoxy. Heal well according to the instructions.

- Silicone coating: There is flexibility, good heat resistance, and is essentially a non-toxic medical/food grade. Can be diluted.

- avoid: Hobby grade polyurethane, acrylic, epoxy resin no Clearly obtain certification for food contact. "Food Safety" Sprays or waxes are not usually suitable for porous 3D printing.

Post-processing application prompts

- Thorough cleaning: Check and clean the items first.

- Ventilation: Resin smoke during the healing process can be harmful.

- Apply correctly: Thin, even the coat is better than the thick earth to avoid cracking or incomplete curing.

- Completely cured: Follow the manufacturer’s healing time specifications Exactly. Hurry up and invalidate the security certification.

Conclusion: A practical and scientific method

choose "Safe" Food contact with 3D printed filaments needs to go beyond simple labels. This is a materials science challenge with its inherent polymer properties, additive safety, inevitable porosity and the grim reality of chemical migration in dynamic food environments.

- Priority to certified PET or PP On PLA Material Inherent food contact performance is better, but understand their printing challenges.

- Assume that all original FDM prints have dangerous porosity. Strict post-processing Certified food safety coatings In addition to short-term cold drying, non-porous barriers must be achieved.

- Resist the use of prints for high-risk applications Items like baby bottles, hot drink cups, acid foods stored for a long time or harsh dishwashing cycle unless professionally printed in PP, perfectly sealed and rigorously tested.

- Critical thinking: Does novelty require complexity and potential risks? Sometimes, traditional food-grade materials manufactured through standard processes may still be a safer option.

3D printing offers incredible creativity, but applying a lot of materials science reveals the careful considerations needed to bridge the gap between plastic creation and edible content. Safety comes from understanding the complex interactions of chemistry, physics and responsible completion techniques. Step on carefully and print wisely.

FAQ: Get rid of mysterious food safety 3D printing

-

Q: Is PLA food safe?

- one: Pure PLA resin has low inherent toxicity but Commercially available PLA filaments typically contain non-food safety additives for color, stability, or ease of printing. It is crucial that The porous nature of FDM prints makes PLA objects unsafe for functional food contact unless professionally sealed. Think of it as only for sealed decorations or very short-term contacts.

-

Q: What is the best true food safety silk?

- one: No perfection "Plugin" Solution. Polypropylene (PP) With its wide range of food packaging, chemical resistance and dishwasher durability, it has the greatest hope. However, it is very difficult to print. Certified food grade Petg It is a more practical option for most users who are willing to carefully seal prints. this "The best" Depends on the specific application and your printer’s functionality.

-

Q: Can I put sealed 3D prints in the dishwasher?

- one: Caution, maybe The only one if:

- It is made of high temperature materials such as PP (preferred).

- Use high-quality, certified food safety sealant for prolonged heat exposure and Perfect application.

- It is placed on the top rack away from the direct heating element.

- You understand that it will degrade faster than molded products. Spots; PET can warp. Washing hands is always safer to live longer.

- one: Caution, maybe The only one if:

-

Q: How can I Appropriate Seal my prints for food contact?

- one: Thoroughly polished, then multi-layered Certified food safety epoxy resin (Complied with standards such as FDA CFR 175.300) is the most common and effective method. Heal well according to the instructions of the resin in a well-ventilated area. Silicone coatings are another option. Surface preparation (cleaning, degreasing) is crucial. Hobby sprays/waxes are ineffective for real pore seals.

-

Q: Is it safe to print a cookie cutter?

- one: Cookie Cutter Representative Relatively High-risk ratio container (short contact, cold use). However, porosity captures the original dough and contamination. Use food safety certified filaments (ideally PETG/PP), then Thorough sealing cutting machine Before first use. Always wash immediately after use and make sure they are completely dry. Minimize stagnation between uses.

- Q: Why can’t I just use plastics marked as food safe? (e.g. plastic containers)

- one: Industrial plastic containers are injection molded or thermoformed to form solid, non-porous surfaces. FDM printing essentially builds objects layer by layer, creating microscopic gaps and gaps that are very suitable for bacterial growth. this process The porosity problem avoided by manufacturing food safety plastics is introduced.

Experience uncompromising accuracy and security

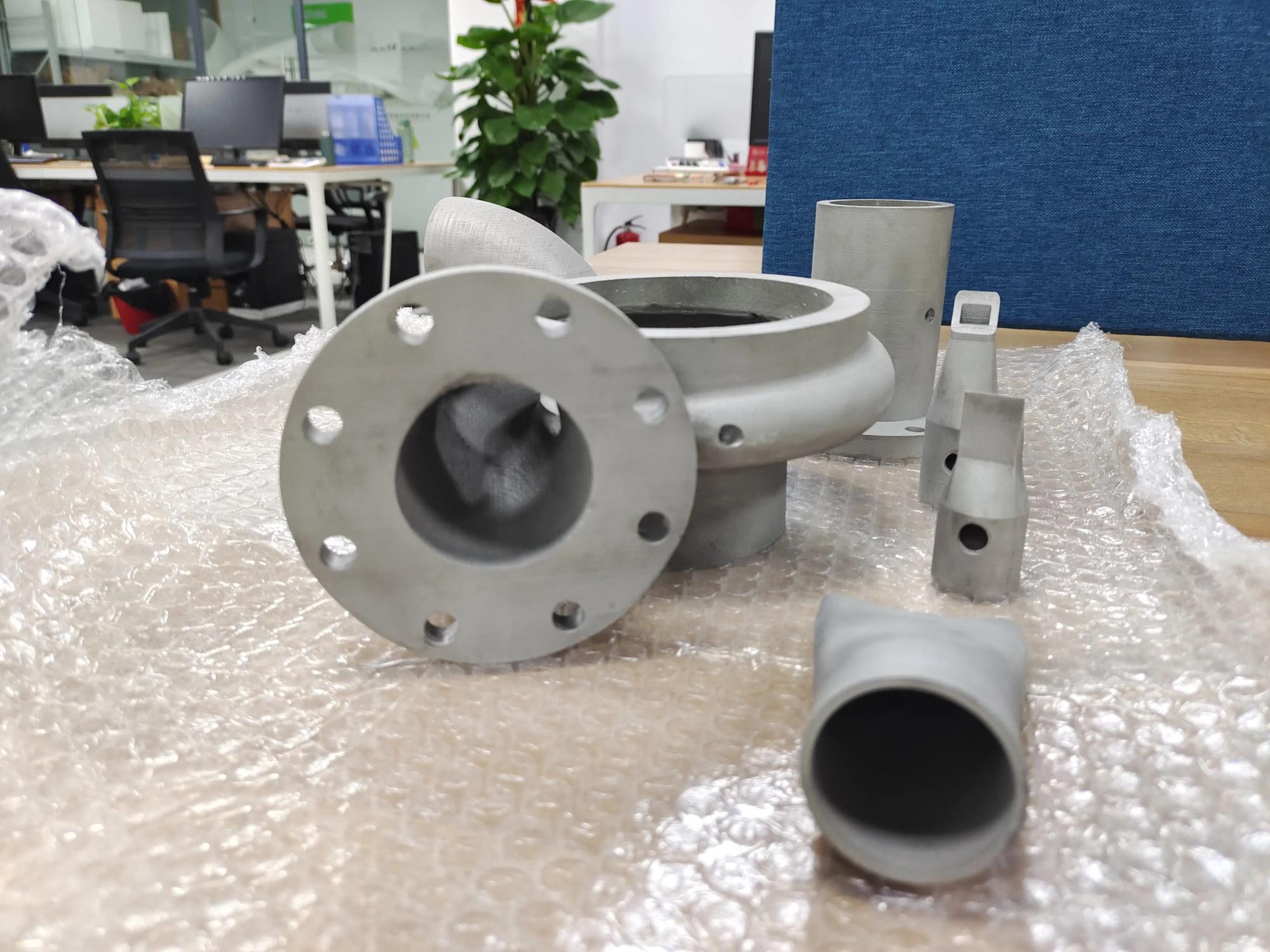

Careful DIY science is required when browsing the complexity of food-safe filaments, Great Provides powerful solutions for critical food contact applications: Precision metal 3D printing uses selective laser melting (SLM).

As a leading rapid prototyping manufacturer, we overcome the fundamental limitations of FDM plastics:

- Born to be without holes: SLM builds parts on atoms, forming a completely dense, impermeable surface – eliminating bacterial hidden points.

- Wide material freedom: Print with certified food grade stainless steel (such as 316L), titanium alloys and other naturally safe, ultra-durable metals.

- Excellent performance: Unparalleled heat resistance, chemical inertia, mechanical strength and durability – more than any plastic.

- End-to-end quality: From expert design for manufacturability to comprehensive medical/food-grade post-treatment (mirror electropolishing, passivation), we ensure that parts meet stringent safety and hygiene standards.

- Quick customization: Need complex, sturdy, truly food-safe parts? Our advanced technology can be iterated and produced quickly.

Go beyond the limitations of filaments and enter the field of ensuring safety and performance. Gregthile is your partner, requiring uncoordinated prototyping and production parts of porosity and material safety.

Customize your precision food-grade parts now. Contact Greatlight now for the safest and most durable rapid prototyping and production solutions.