Over the years, the world of 3D printing has evolved significantly, with advances in technology and equipment making it easy to create complex parts and products. One area that has attracted widespread attention in recent years is the creation of AR-15 3D printed files. For those unfamiliar, the AR-15 is a popular semi-automatic rifle that has been widely used in entertainment, hunting and even military applications.

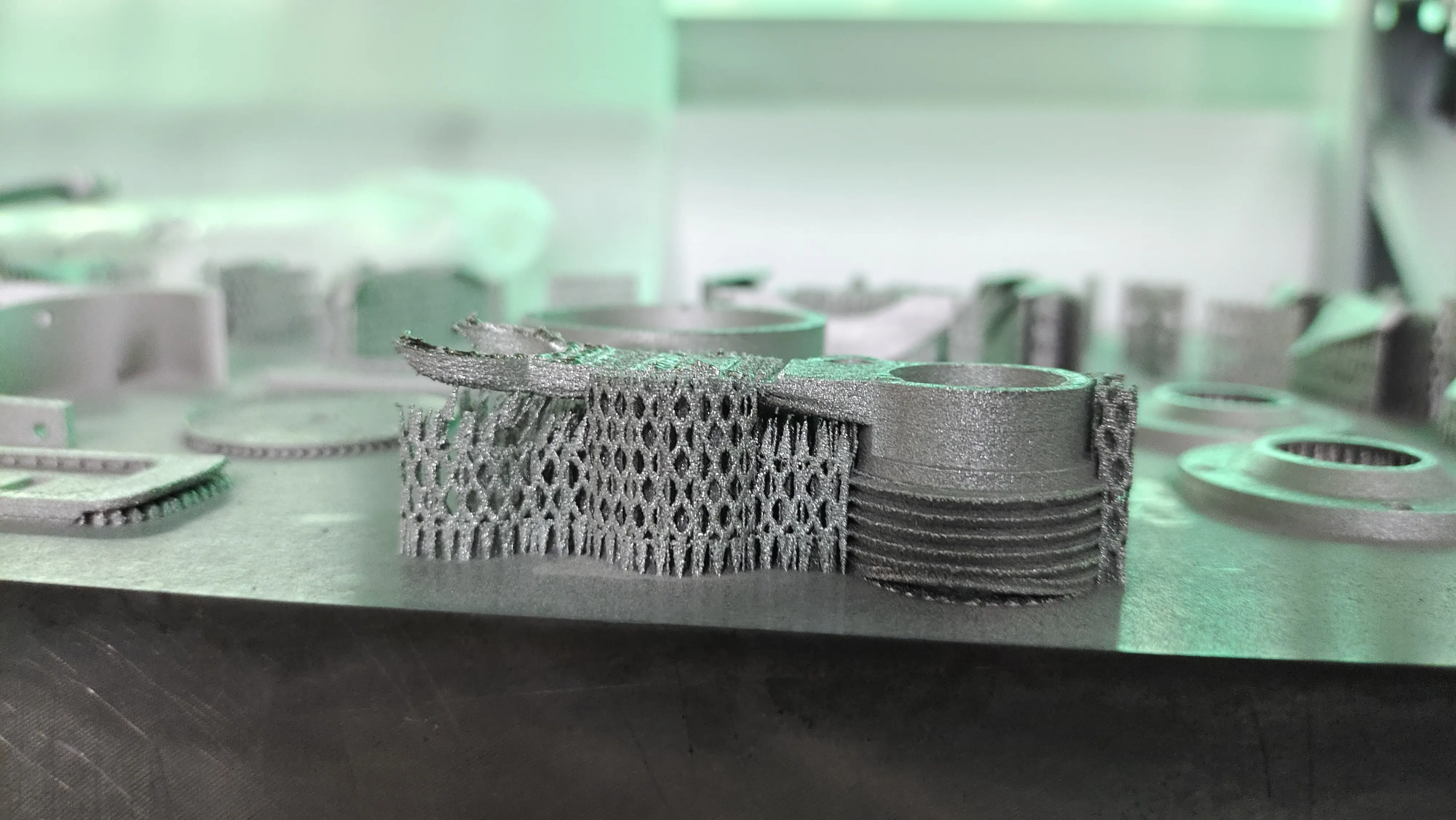

For those interested in creating their own AR-15 using 3D printing technology, there are several factors to consider. First, a high-quality 3D printer that can produce parts with the necessary accuracy and accuracy must be used. This is where companies like Greatlight come into play, offering advanced SLM 3D printing equipment and production technology that can help solve complex metal parts rapid prototyping problems.

Several design considerations must be considered when creating AR-15 3D printed files. For example, the design must ensure that the printed parts are compatible with existing AR-15 components such as the lower receiver, upper receiver and barrel. In addition, the design must also take into account the mechanical properties of the printed parts such as strength, durability and resistance to fatigue.

From a manufacturing perspective, creating an AR-15 3D printed file requires in-depth understanding of basic technologies and materials science. Here, Greatlight’s expertise in rapid prototyping comes into play, and the company offers a one-stop post-processing and completion service that can help ensure printed parts meet the required specifications.

One of the important advantages of using 3D printing technology to create AR-15 parts is the ability to customize and personalize the design. With 3D printing, complex geometric shapes and shapes can be created that are difficult or impossible to produce using traditional manufacturing methods. This enables gun enthusiasts to create unique and custom-made AR-15 designs to meet their specific needs and preferences.

When it comes to materials, most 3D printing services offer a range of options, including metal, plastic and ceramics. When creating AR-15 parts, metals such as aluminum and steel are often used due to their high strength to weight ratio and corrosion resistance. For example, Greatlime can use a wide range of materials, including custom and proprietary materials, to produce high-quality AR-15 parts.

In short, creating an AR-15 print file requires in-depth understanding of 3D printing technology, materials science, and design principles. With the right equipment, expertise and materials, high-quality AR-15 parts can be created that meet the required specifications. Companies like Greatlight are at the forefront of this technology, offering advanced SLM 3D printing equipment and production technologies that can help solve complex metal parts rapid prototyping problems.

FAQ:

Q: What is the best material to create AR-15 3D printed files?

A: The best material for creating AR-15 3D printed files depends on the specific application and requirements. Because metals such as aluminum and steel are commonly used due to their high strength to weight ratio and corrosion resistance.

Q: Can I use 3D printing technology to create a fully functional AR-15?

A: Yes, 3D printing technology can be used to create a fully functional AR-15. However, this requires a deep understanding of 3D printing technology, materials science and design principles, and the use of high-quality 3D printing equipment.

Q: Is AR-15 3D printed files legal?

A: The legality of AR-15 3D printed documents varies by jurisdiction and local law. In some countries, it is legal to create and own 3D printed firearms, while in others it is strictly prohibited. Local laws and regulations must be checked before attempting to create or own a 3D printed firearm.

Q: Can I use 3D printing technology to customize the AR-15 design?

A: Yes, one of the important advantages of using 3D printing is the ability to customize and personalize the design. With 3D printing, complex geometric shapes and shapes can be created that are difficult or impossible to produce using traditional manufacturing methods.

ISO 9001 Factory