3D Printer Filter Housings: Your Essential Guide to Cleaner Air and Better Prints

The whir of a stepper motor and the subtle smell of melting plastic are probably familiar sounds and smells in your workspace. But did you know that standard desktop 3D printers release ultrafine particles (UFP) and volatile organic compounds (VOCs) during operation? These emissions pose potential health risks and can even affect the quality of your prints. Enter necessary upgrades: 3D printer filter housing.

This guide delves into the critical role of filter housings, exploring why they are an essential addition to your print setup, how they work, what options exist and how to choose the right filter housing for your needs.

Why your non-enclosed printer needs a filtration system

- health care: This is the most important thing. When heated plastics like ABS, nylon (PA), ASA and even PETG are extruded, they release:

- Ultra-fine particles (UFP): Particles less than 0.1 microns in diameter can penetrate deep into the lungs and even enter the bloodstream. Inhalation is associated with respiratory irritation and long-term health problems.

- Volatile organic compounds (VOC): Harmful gases such as styrene (from ABS/ASA), caprolactam (from nylon), aldehydes, and other pyrolysis byproducts can cause headaches, nausea, dizziness, and eye/nose/throat irritation. often with "Printing smell."

- Print quality enhancements: A stable thermal environment significantly improves print quality.

- Prevent drafts: The casing blocks external airflow that can cause temperature fluctuations around the print, thereby reducing warping (especially important for ABS, PC, ASA).

- Maintain a consistent temperature: Keeping warm air within the build volume promotes layer bonding, minimizes cracking, and improves dimensional accuracy of thermally sensitive materials.

- Material integrity: Certain engineering materials require elevated ambient temperatures to prevent stress and delamination. The enclosure provides this stable microclimate.

- Safety: In the rare event of thermal runaway, the enclosure may contain sparks or small hot particles.

- Reduce noise: The main body of the enclosure acts as a physical barrier, suppressing motor and fan noise.

- contain: Limit loose filaments, stray plastic strands and dust.

How the filter housing works: Filtration principle

A typical filter housing combines physical sealing with active air cleaning:

- Containment box: There is a sealed (or semi-sealed) chamber surrounding the printer that traps emissions inside.

- Air recirculation: An integrated fan draws contaminated air from the housing into the filter unit.

- Multi-level filtering: The air passes through:

- Pre-filter: Captures larger particles such as dust and print debris, protecting the more expensive primary filter and extending its life.

- Main filter (core): This is where key contaminants are captured:

- Activated carbon filter: Special charcoal with a huge surface area captures volatile organic compounds and gases through adsorption. Efficacy varies widely; look for dense granular carbon optimized for VOC capture.

- HEPA filter: High-efficiency particulate air filters remove at least 99.97% of airborne particles as small as 0.3 microns, capturing UFPs, allergens and fine dust. HEPA H13/14 is ideal.

- Purified air recirculation: The purified air is returned to the housing, creating a continuous filtration cycle.

Browse your options: Types of filter housings

-

Commercial off-the-shelf enclosures:

- Integrated system: Complete kit (box + filter + fan) designed for a specific printer or popular model. Typically optimized for performance and aesthetics (e.g. AdditiveAir, Clever Filter, Bentobox). Pros: Plug and play, guaranteed performance specifications. Disadvantages: higher cost, fixed size.

- Universal printed housing kit: Flat-pack DIY kits that you assemble yourself (for example, an Ikea Lack set for your printer). Advantages: low cost, strong adaptability to floor space. Cons: Requires assembly/time, sealing/venting requires DIY effort, aesthetics vary. Commercial aftermarket filters can be installed.

- Dedicated filter module: Self-contained filtration units are designed to be installed into existing enclosures or cabinets (commercial or DIY). Advantages: Concentrated filtration capacity and easier replacement. Disadvantage: Requires existing sealed chamber.

- DIY case (beyond the basic box):

- Material: Fire retardant acrylic sheets, wood composites, modified cabinets/printer tables, thick plastic sheeting.

- Key factors: Effective sealing. Focus on seams, doors, cable entry points, and filament paths. Unsealed enclosures can dramatically leak contaminated air.

- Integrated filters: Installing a commercial universal filter module in Well-sealed DIY boxes are often the most cost-effective and High performance solution.

Choosing the Right Filter Housing: Key Considerations

Don’t buy blindly. Evaluate based on your specific needs:

- Printer dimensions and compatibility: Make sure internal dimensions provide adequate clearance for all printer movement, wiring, spools (internal or external feed mechanism), and tall prints. Check specific mounts if needed.

- Main printed materials: This determines the filtering requirements.

- ABS/ASA/Nylon/PC: Non-negotiable – VOC filtration (activated carbon) and particle filtration (HEPA) required. Commercial solutions with proven VOC reduction data are highly recommended.

- PLA/PETG/Tough PLA: Mainly requires particle filtration (HEPA). VOC levels are significantly reduced, but still present. Activated carbon adds a valuable safety margin. Essential if you are printing large volumes or printing within a occupied space.

- Resin printing: While curing also releases volatile organic compounds, the shell also protects against UV rays. Filtration needs are similar to ABS/nylon. no way UV resin printers should be operated uncovered.

- Print space: Where is the printer? A home office or bedroom requires higher filtration efficiency and sealing than a large, well-ventilated garage workshop.

- Required filter performance:

- Carbon filter: Look for weight and particle size/density. More kg/g of high-quality carbon improves VOC adsorption capacity and service life.

- HEPA filter: Stick with true HEPA grades (H13 or H14). Be careful "Similar to HEPA" marketing.

- Air flow (CADR): How many cubic feet per minute per meter per hour (CFM/m3/h) does the system circulate? Higher CFM means faster air exchange, resulting in faster cleaning. Maintain a balance with noise levels.

- Security certification: Look for UL listed components (especially fans/heating elements) and RoHS compliance (if applicable). Flame retardant materials are a plus.

- Easy to use and maintain:

- Accessibility: Frequent filter changes require easy access. The value of a pop-up latch is priceless.

- Filter replacement cost/availability: Consider ongoing costs and ease of procuring replacement filters.

- Monitoring: Some advanced systems integrate VOC/AQI sensors.

- Noise level: Fan noise determines practicality. Look for a system with a specified decibel (dB) rating that is suitable for your environment.

- Budget: Prioritize safety/health. A strong system is an investment. Avoid options that are too cheap and compromise effectiveness.

Maintenance Lifeline: Keeping Filters Effective

Unmaintained filters can quickly become ineffective:

- Pre-filter: Replace monthly (or visually inspect/clean reusable foam types).

- Activated carbon filter: The frequency of replacement depends largely on the printing time and material type. Read the manufacturer’s guidelines. Usually every 3-12 months. Manufacturer’s adsorption capacity test data are a reliable guide.

- HEPA filter: Usually lasts longer (1-2 years), but is subject to regular inspections. If damaged or clogged, replace immediately.

- Visual inspection and monitoring: Check regularly for blockages. System airflow noticeably reduced? Increased odor? It’s time to replace the filter.

- Follow manufacturer schedule: Adhere to recommended replacement intervals based on rigorous testing.

Working with professionals: combination of housing and finished product manufacturing

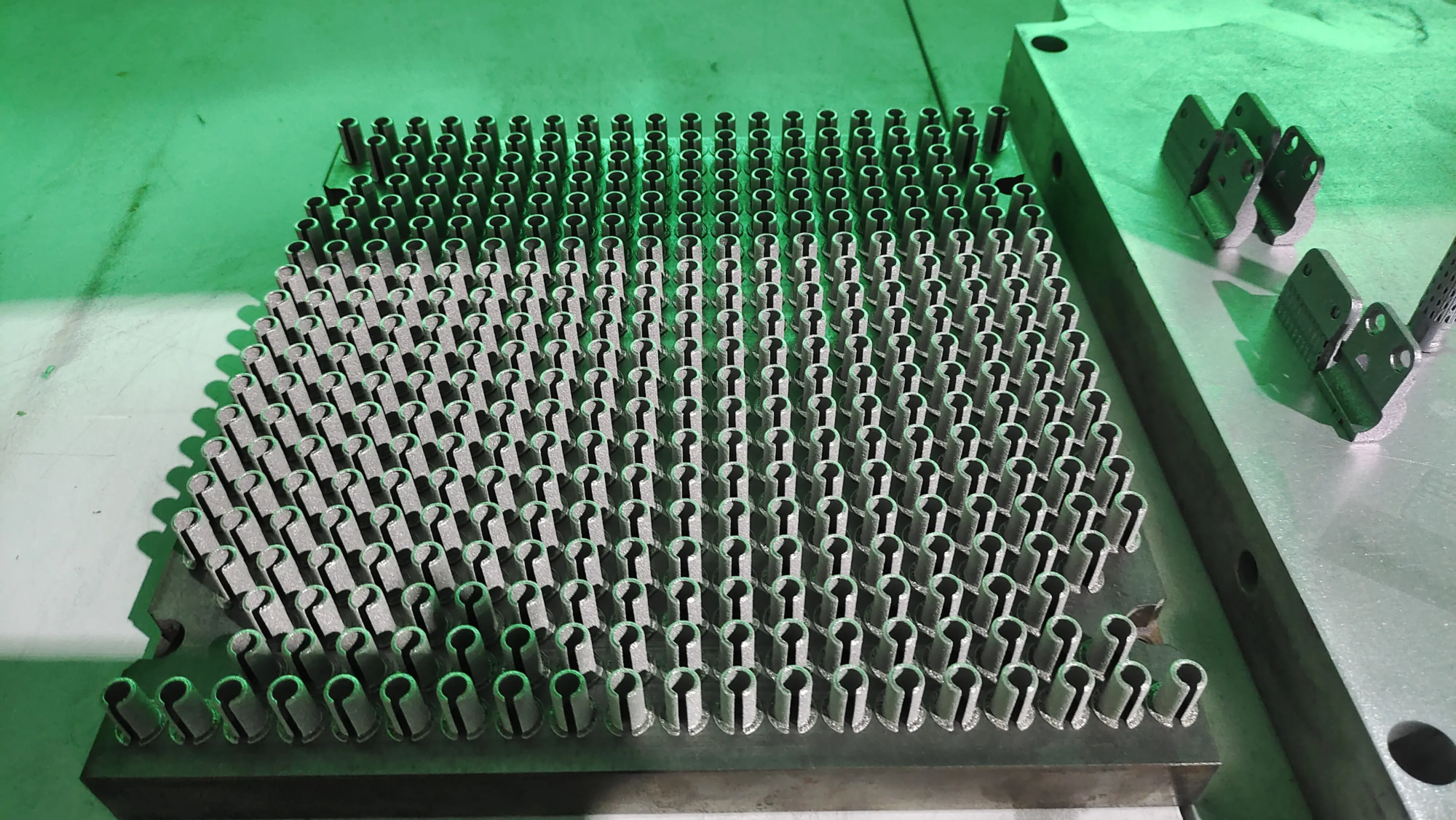

Controlling emissions from rapid prototyping processes isn’t just for hobbyists. Professional environments require rigorous solutions. huge lightthe leader in professional rapid prototyping, embodies this commitment. GreatLight operates advanced SLM (selective laser melting) metal 3D printers as well as polymer systems and understands the critical need for controlled environments and emissions management throughout the additive manufacturing workflow. Their expertise goes beyond printing:

- equipment: Ensure operator safety and optimal printing conditions with an industrial-grade enclosure and ventilation/filtration system integrated with SLM and polymer printers.

- Materials Science: Gain insight into the emission profiles of different polymers and metals.

- Post-processing: Offering a comprehensive one-stop service, including finishing and handling steps (usually occurring in a controlled environment), delivering production-ready parts.

- custom made: Provides rapid custom manufacturing of precision metal prototype parts utilizing closed systems for critical aerospace, automotive and medical applications requiring stringent material properties and dimensional accuracy.

Whether you are iterating on prototypes in-house or leveraging expert services like GreatLight for end-use production, a controlled environment supported by effective filtration is critical to the responsible use of 3D printing technology.

Conclusion: Investing in health and quality

A 3D printer filter housing is more than just an optional accessory; it’s a fundamental investment in the health and safety of everyone nearby and in the quality and reliability of the printed parts. By understanding the risks posed by particulate matter and VOC emissions, how filtration addresses these risks, and the factors involved in choosing the right solution, you can create a safer, more efficient printing environment. Prioritize strong seals, proven filtration performance (HEPA + premium VOC adsorption) and proactive maintenance. Balancing DIY ingenuity with professional solutions where health risks require certainty. Embrace responsible printing—prioritizing clean air.

Frequently Asked Questions (FAQ): 3D Printer Filter Housing

1. Is a housing with a filter really necessary? Can’t I just open a window?

For occasional PLA printing in very large, well-ventilated spaces (such as a garage with an open door), rely on only For hobby-level health, natural ventilation may be barely acceptable (although UFP is still an issue). However:

- Opening a window does not reliably remove VOC/UFP near the source area of the printer fast enough.

- This is not enough for ABS/ASA/nylon/resin – ventilation must be combined with active filtration near the source to ensure safety.

- Window ventilation can introduce airflow that is detrimental to print quality (causing warping/cracking).

- In a bedroom, office or apartment, it’s not safe to rely on ventilation alone – filtration is non-negotiable.

2. Which filter combination is absolutely necessary?

For important printing activities, especially using any of ABS, ASA, Nylon, PC or resin:

- Activated carbon: Used to adsorb harmful VOCs/gases (necessary in addition to PLA).

- True HEPA filter: For capturing hazardous UFPs and particles (for all Material).

A separate pre-filter protects and extends the life of these expensive main filters. Don’t compromise on these core elements.

3. How often do I need to change the filter?

This depends heavily on printing frequency, materials used, and filter size/quality:

- Pre-filter: Monthly cleaning/replacement (visual inspection).

- Activated carbon: become saturated. Replace every 3-12 months (carefully follow manufacturer’s instructions depending on usage/materials). The loss of effectiveness is evident through the lingering odor.

- HEPA filter: Typically lasts 1-2 years, but check regularly for reduced airflow (blockage) or damage. Replace when airflow drops significantly.

4. Can I build a DIY enclosure cheaper that actually works?

Yes, it’s possible, and it’s often worth it. However:

- Security cannot be compromised: Extreme attention is paid to airtight sealing. Leaks can significantly reduce efficacy.

- Use sturdy materials: Avoid using flammable plastics. Fire retardant acrylic/plexiglass or treated wood composites are safer.

- Prioritize appropriate filtering modules: Combined with a proven commercial activated carbon + HEPA filter unit designed for a specific purpose in Your sealed box. Don’t rely on basic DIY air purification.

- Integrate a suitable fan: Ensure adequate airflow (CFM) for housing volume and filter resistance.

5. Does the enclosure have temperature control?

Most basic consumer enclosures primarily capture ambient heat from the printer bed/heater block. This is enough for printing materials such as ABS (ambient temperature preferably >45C). High temperature materials such as polycarbonate (PC) sometimes benefit from additional heating elements controlled by slicers/controllers to maintain higher stable temperatures (60-70C+), but these require careful design and fire safety considerations. Verify that the enclosure is suitable for any active heating elements used inside.

6. What role does GreatLight play in filtering and prototyping?

huge light As a professional rapid prototyping manufacturer, utilize industrial-grade closed systems for complex additive processes such as selective laser melting (SLM metal printing) and polymer printing. They prioritize emissions management, operator safety, thermal stability, and a controlled environment that achieves consistent, high-quality results. This means reliable production of functional metal prototypes and parts that require tight tolerances and material properties. their comprehensive "one stop shop" The approach includes post-processing (carefully performed in a controlled environment) that streamlines the process from CAD model to finished component. For complex projects that require enclosure-level precision and reliability from the start, working with experts like GreatLight ensures the best possible results.

Ready to improve your prototyping safety and success? Discover responsible, closed solutions for your next project.