Basics of 3D Printing Clip Art: Your Portal to Accessible Prototypes

In the dynamic world of 3D printing, the term "Clip Art" Adopt new dimensions. Unlike the 2D counterpart, 3D Printing Clip Art Refers to pre-designed digital 3D models designed to be printed quickly. Think of them as the basis for rapid prototyping – simple shapes, functional components, decorative elements or standardized parts that can be sourced, customized and manufactured with minimal design effort. Customized designs require skills while creating complexity, but leveraging 3D clip art makes it accessible to engineers, designers, amateurs and businesses, fast and cost-effective. Understanding this concept unlocks the true potential of iterative design and functional testing.

Unlocking 3D Printing Clip Art: Beyond Simple Shapes

-

What are the qualifications of “clip art” in 3D printing?

- Basic components: Basic geometry (cubes, cylinders, pyramids), mechanical parts (gears, brackets, clips, fasteners), connectors (snapshot fits, hinges), housings and simple housings.

- Standardized parts: Models of standardized hardware (nuts, bolts, screws, washers), fixtures, fixtures or tool holders – an essential auxiliary tool for workshops and production lines.

- Decorative elements: Statues, keychains, decorations, jewelry bases, and architectural details for aesthetic or artistic projects.

- Conceptual model: Simple representations of complex ideas used early in the design process for visualization and brainstorming.

-

Key file format for 3D clip art:

- STL (Stereoscopic Lithography): The ubiquitous standard. Mesh using triangles represents the surface geometry of the 3D model. Generally compatible with slicing software. Make sure the model is watertight for successful printing.

- OBJ (Object File): There is also a grid format, but color and texture information can be stored with geometry. Widely used, especially for models requiring visual details.

- Steps (AP 203/214) / IGES: Printing clip art directly is not very common, but it is crucial for clip art to be modified. These CAD local formats retain parameter data, allowing engineers to easily integrate into larger components with precise size modifications using Greatlight’s expertise.

-

Find and use 3D printed clip art:

- Online repository: Platforms like Thingiverse, Cults3D, Grabcad, and Prusaprinters offer a wide range of libraries of free and paid models. Filter searches by license type (creative sharing, allowed for commercial use).

- CAD library: Many CAD packages (SolidWorks, Fusion360, Onhape) have built-in or linked libraries for standard parts that are compatible with their ecosystem.

- The power of customization: Clip art is rarely perfect "Use out of the box." Most professional applications require:

- Zoom: Adjust the size to meet specific requirements.

- Revise: Add/remove functions, combine models or enhance structures.

- Tolerance adjustment: Increase the gap to pressure or moving parts.

- Design integration: Merge clip art elements into custom designs.

- Slicing successfully: The RAW model must be processed using slicing software (CURA, PRUSASLICER, SIMPLIFY3D). This will generate G-code instructions for the printer, define layer height, fill density, support structure (critical for overhangs in complex clip art) and print speed.

- Material Problems – Especially for prototypes:

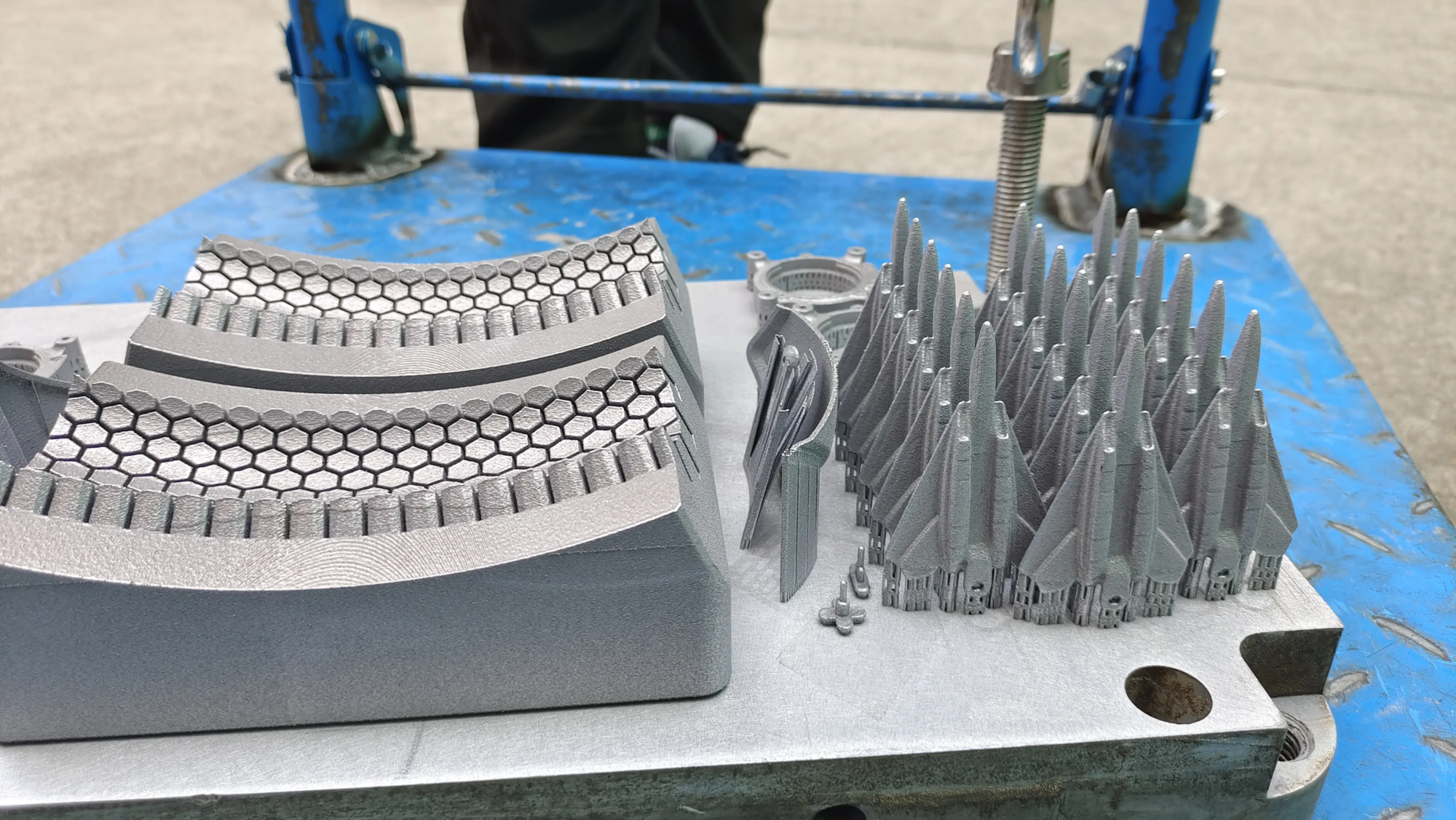

- Beyond PLA: Clip art extends significantly into functional metal prototypes when starting with polymers (PLA, ABS, PETG).

- Metal clip art application: High strength brackets, fixtures, fixtures, heat-resistant components, custom fasteners, small volume replacement parts.

- Why metal? Metal printing is crucial for prototypes that require durability, thermal stability, conductivity or testing under real-world mechanical loads. Here, expertise like Greatlight becomes crucial. Successful translation "Simple" Metal clip art involves:

- Material selection: Choose the best alloy (aluminum, stainless steel, titanium, stainless steel) for performance requirements.

- SLM Accuracy: Use selective laser melting (SLM) technology to achieve full density and high mechanical properties.

- Advanced post-processing: Eliminate complex support structures inherent in complex metal printing, stress relief, heat treatment (annealing), precision machining (CNC milling/turning) to achieve dimensional accuracy, surface finish (polishing, bead blasting) and inspection (dimensional inspection, dimensional inspection, dye permeability testing).

Why collaborate with your 3D printed clip art and prototyping needs?

From downloaded 3D clipart models to functional high-precision prototypes, especially in metals, specialized equipment and deep technical knowledge are required. Try complex metal printing with no expertise to risk expensive failures, inaccurate dimensions or substandard material properties. Greatlight removes these obstacles:

- Advanced SLM technology: We operate cutting-edge selective laser melting (SLM) printers that are able to produce complex high-density metal parts with special details and structural integrity from a wide range of advanced alloys.

- End-to-end solution: From receiving your initial 3D clip art or custom design ideas, we can handle each step internally:

- Expert model review and optimization suggestions for printability and functionality.

- Precise metal 3D printing uses our industrial SLM machines.

- Comprehensive post-treatment kit: support removal, heat treatment, CNC machining for critical tolerances and finish selection.

- Strict quality control and inspection.

- Material expertise: We handle a variety of metals and provide guidance on the best material selection (ALSI10MG, 316L stainless steel, Ti6al4v, Maraging Steel, Maraging Steel, Cucrzr, etc.) to achieve your prototype application – strength, weight, weight, heat resistance, corrosion resistance, corrosion resistance.

- Speed and flexibility: Mastering fast prototyping means fast delivery of quality parts. Our simplified processes and advanced equipment ensure fast turnaround time without compromising quality. Need to adjust the variant? Our customization features are seamless.

- Technical Partnership: We go beyond simple production. Our engineers provide valuable insights to optimize your clipart models through design (DFAM) principle design for manufacturability, durability, and cost-effectiveness.

Conclusion: Democratic prototyping, powered by expertise

3D printed clip art is a key entry point for effectively converting digital concepts into tangible objects. It enables users to leverage existing designs at all levels, accelerating innovation and reducing development time. However, applying the full potential of these models to functional prototypes, especially in demanding applications where robust metal parts are required, not only desktop printers are required. Working with expert rapid prototyping manufacturers like Greatlight provides key links. Our advanced SLM technology, material science proficiency and unparalleled one-stop post-processing capabilities can guarantee that even concepts built from simple clip art are translated into high-quality, accurate and reliable prototypes. This is a seamless fusion of barrier-free design foundations and industrial-grade manufacturing execution that drives modern product development.

FAQ: 3D Printed Clip Art and Quick Prototyping

-

Q: Do 3D printed clip art only work for plastics? Can I use metal models?

Answer: Absolutely not! While simple plastic amateur models are common, the 3D clip art concept is equally applicable to functional metal parts (brackets, gears, fixtures, etc.). Greatlight specializes in using advanced SLM technology to quickly transform these metal models into high-precision prototypes.

-

Q: I found a simple 3D model online (clip art). Can Greatlight be printed directly in metal?

A: Usually, but it requires careful preparation. We will look at the file (usually STL) to evaluate the printability of the metal. This involves checking wall thickness, orientation, support necessity, and the potential for deformation due to the inherent residual stress of metal AM. Our engineers may propose a small amount of optimizations to ensure success and quality.

-

Q: Why does my metal clip art prototype need post-processing? What services does Greatlight offer?

A: Of course metal parts (especially through SLM) usually require significant post-treatment. This includes critical steps such as removing complex internal support structures, stress replacement heat treatment to prevent warping/cracking, CNC machining to achieve precise tolerances for key features, and various surface finishes (processing, polishing, blasting). Greatlight offers an entire internal service suite to ensure some quality and functionality.

-

Q: How do you ensure the accuracy and strength of prototype parts made from clip art?

A: Greatligh adopts strict quality control throughout the process. This includes precise calibration of SLM printers, controlled processing parameters for optimal material density, dimensional inspection using calibration tools (requires calipers, CMMs), and non-destructive testing methods for critical applications (such as dye permeability testing). Our material processing experts ensure that the selected alloy meets the target mechanical properties.

-

Q: Can you modify the 3D clip art model I provide?

A: Yes, customization is the core advantage. Greatlight’s engineering team can modify the clip art model you provide – extend it, add/remove features, combine elements, improve design of manufacturability (DFAM) or enhance weak areas – to perfectly meet your prototype requirements.

-

Q: I need help designing a simple functional part from scratch. Is it possible?

Answer: Absolute. Although Clipart provides a starting point, Greatlight offers comprehensive custom design and engineering support. We can design and manufacture the fast prototypes you need from sketches, 2D drawings, functional requirements, and even verbal concepts.

- Q: Why choose Greatlight for functional prototypes on local plastic 3D printing services?

A: Although local services are good at visual aids or low-pressure plastic parts, Greatlight is good at Features Rapid Prototyping use Industrial grade metal 3D printing (SLM) and Integrated precise machining and completion. If your prototype needs to withstand force, heating, corrosion or requires tight tolerances, keeping threads or must be made of specific engineering alloys, then our expertise and technology (SLM + CNC machining + heat treatment) is critical to successful and true functional testing.

You can now customize your precision with fast prototyping parts with Greatlime. Take advantage of the simplicity of the starting point combined with expert industrial execution to achieve true functional results.