Unleash creativity: The ultimate guide to choosing the best coatings for PLA 3D printing

Now you’ve mastered the art of 3D printing PLA parts. Whether it’s a detailed prototype, a role-play prop or a functional component, your creation deserves perfection. Paint transforms amateur PLA prints into professional-grade pieces – enhancing beauty, hiding layer lines, and even adding a protective layer. But which paint actually does this? Let’s dive into the science and art of PLA painting and gain industry insights to enhance your projects.

Why apply PLA? beyond aesthetics

PLA (polylactic acid) is biodegradable, user-friendly and versatile. However, its natural matte finish and visible printed layer need improvement. Painting is more than just color:

- surface strengthening: Smoothes gradation lines and subtle imperfections.

- Protect: Protects against UV degradation and moisture.

- Functional: Increased grip, conductivity (using special coatings) or camouflage.

At GreatLight, we recognize that post-processing such as painting is an integral part of rapid prototyping. Our customers utilize our automated sanding, priming and painting services to achieve museum-worthy finishes on functional parts, ensuring prototypes look and perform like the end-use product.

The Best Coating Choices for PLA: Pros, Cons, and Science-Backed Tips

Not all coatings will bond evenly to PLA. Below, we break down the options based on adhesion, durability, and workflow compatibility:

1. Acrylic paint: the flexible all-rounder

- most suitable: Beginners, intricate details, hand drawing.

- why do they work: Water-based acrylic resin is slightly flexible after curing, which reduces the risk of chipping of easily bendable PLA. They have low odor and are non-toxic.

- advantage: Easy to clean, quick drying, wide color range.

- shortcoming: Not as durable as solvent-based paint; requires primer.

- For tips: Use airbrush acrylics to achieve ultra-smooth gradients – perfect for organic shapes.

2. Spray Paint (Enamel or Acrylic): A Combination of Efficiency and Surface Preparation

- most suitable: Large print with even coverage.

- why do they work: Solvent-based aerosol (such as enamel) chemically etches the PLA surface, producing excellent adhesion.

- advantage: Professional gloss, time saving, self-leveling.

- shortcoming: Risk of overspray; ventilation required. High VOC options require a respirator.

- For tips: Use a heat gun (50-60°C) to slightly heat the PLA before spraying. This opens the polymer pores for deeper paint penetration.

3. Epoxy and polyurethane coatings: industrial armor

- most suitable: Functional parts requiring wear/chemical resistance.

- why do they work: Two-part epoxy forms a covalent bond with PLA to create a rock-solid shield. Polyurethane adds flexible UV protection.

- advantage: Waterproof, impact resistant, high gloss option.

- shortcoming: Complex applications; long cure time (24+ hours).

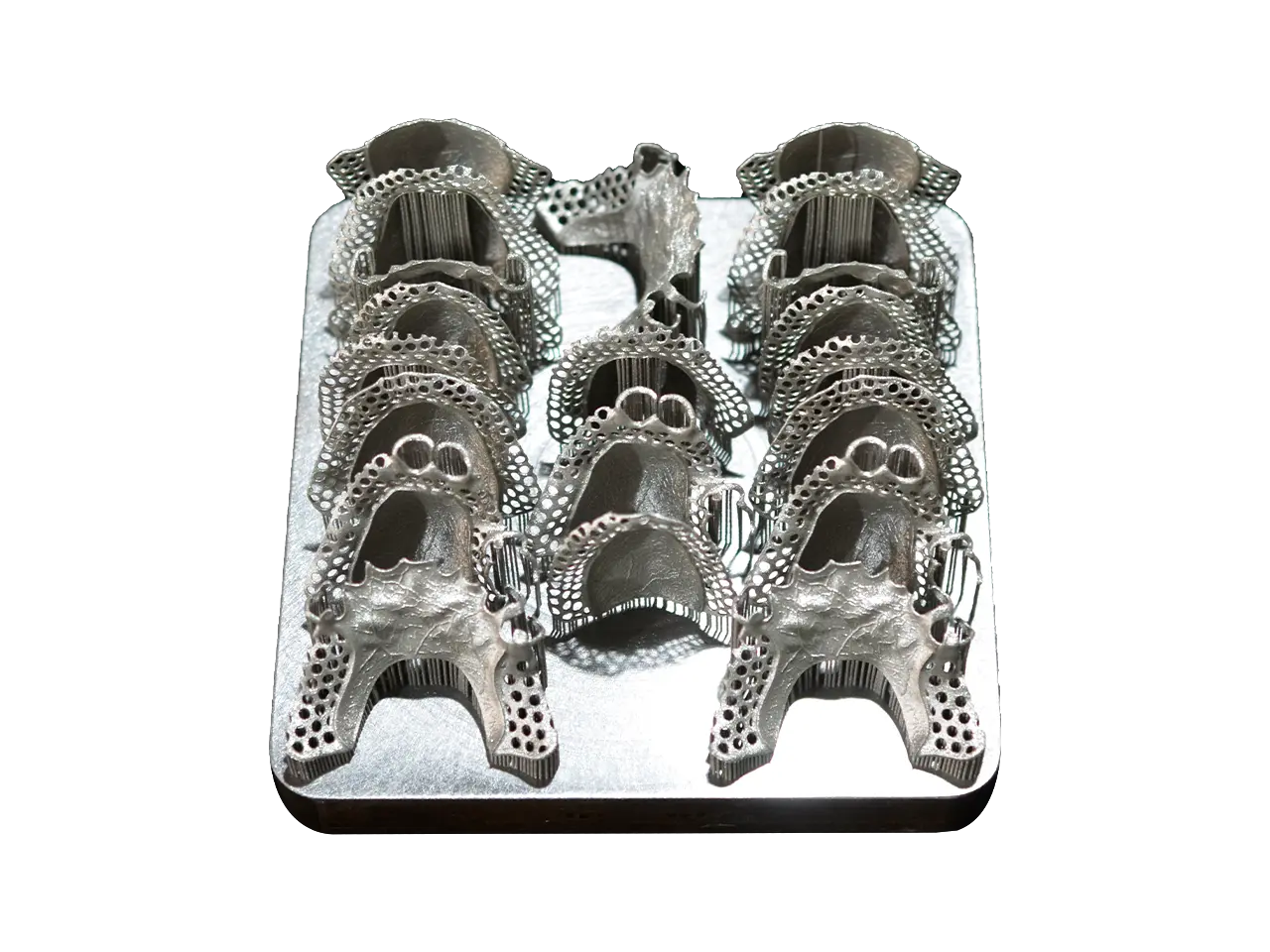

- Industry Insights: At GreatLight, we use automotive-grade polyurethane clear coatings on SLM printed parts to extend life in harsh environments.

4. Specialty 3D printing coatings: the next generation solution

Brands like XTC-3D offer epoxy-based coatings that fill both layer lines and primed surfaces. Ideal for print shops that focus on speed.

Step-by-Step Guide: From Sanding to Presentation

Skip the prep work and even a quality paint can fail. Follow this lab-tested protocol:

- clean: Use isopropyl alcohol (IPA) to remove oil/residues.

- Sanding:

- For major flaws, start with a coarse grind (200 grit).

- Gradually increase to 400-800 mesh to achieve smoothness.

- Automation advantages: GreatLight uses ultrasonic waves to polish complex geometries to achieve consistent Ra <0.5μm.

- start up:

- Use a filling primer such as Rust-Oleum to fill micropores.

- Spray 2-3 thin coats – allow 15 minutes to dry between coats.

- painting:

- Apply the paint in thin, cross-hatched layers.

- Keep a distance of 20-30 cm from the aerosol to prevent dripping.

- clear coat: Seal with acrylic/polyurethane varnish. Matte grip; eye-catching shine.

Conclusion: Where Art Meets Engineering

PLA painting is not an apparent afterthought, but a critical stage in professional prototyping. While a DIY approach offers creativity, industrial-grade finishing, such as auto-primers or UV-resistant sealants, ensures parts can withstand real-world stresses. That’s why pioneers like huge light Integrate post-processing into fast workflows: Our SLM printers produce precise geometries, but this is our One-stop sanding/priming/painting services Convert printed matter into client-usable assets. Ready for the perfect prototype? Partner with an expert who treats finishing as a science.

FAQ: Painting PLA Revealed

Q1: Can I spray PLA without sanding or priming?

Answer: Not recommended. PLA has low surface energy, resulting in poor paint adhesion. The primer forms a chemically receptive layer.

Q2: Why does the paint on PLA crack?

Answer: Usually due to thermal stress. PLA softens at approximately 60°C. Cracking can occur if the paint cures at high temperatures or if thick layers shrink unevenly. Solution: Apply thinly and dry at room temperature.

Q3: Yes "PLA only" Is paint worth buying?

A: They are convenient, but often overpriced. Standard acrylic/enamel works perfectly with proper preparation.

Q4: How to paint flexible PLA without peeling?

A: Use a flexible acrylic (such as Createx) bonded to a flexible primer. Avoid using hard enamel sprays.

Q5: Can GreatLight handle post-processing of multi-material printing?

Answer: Of course. Our facilities support PLA, ABS, nylon and metal blends and provide custom coating systems for each substrate.

Take your prototypes beyond filament shades. For fast printing combined with aerospace-grade finishing, Explore GreatLight’s capabilities——Every layer is important.