The Rise of Functional Innovation: Best-Selling 3D Printing Products Shaping the Industry

The 3D printing revolution has evolved far beyond prototyping. Today, it drives real-world innovation across industries, transforming design concepts into functional end-use products. At GreatLight, we see every day how this technology meets demands for complexity, customization, and speed—from aerospace alloys to personalized medical devices. Below, we explore today’s best-selling 3D printing products and explain why companies are increasingly relying on additive manufacturing.

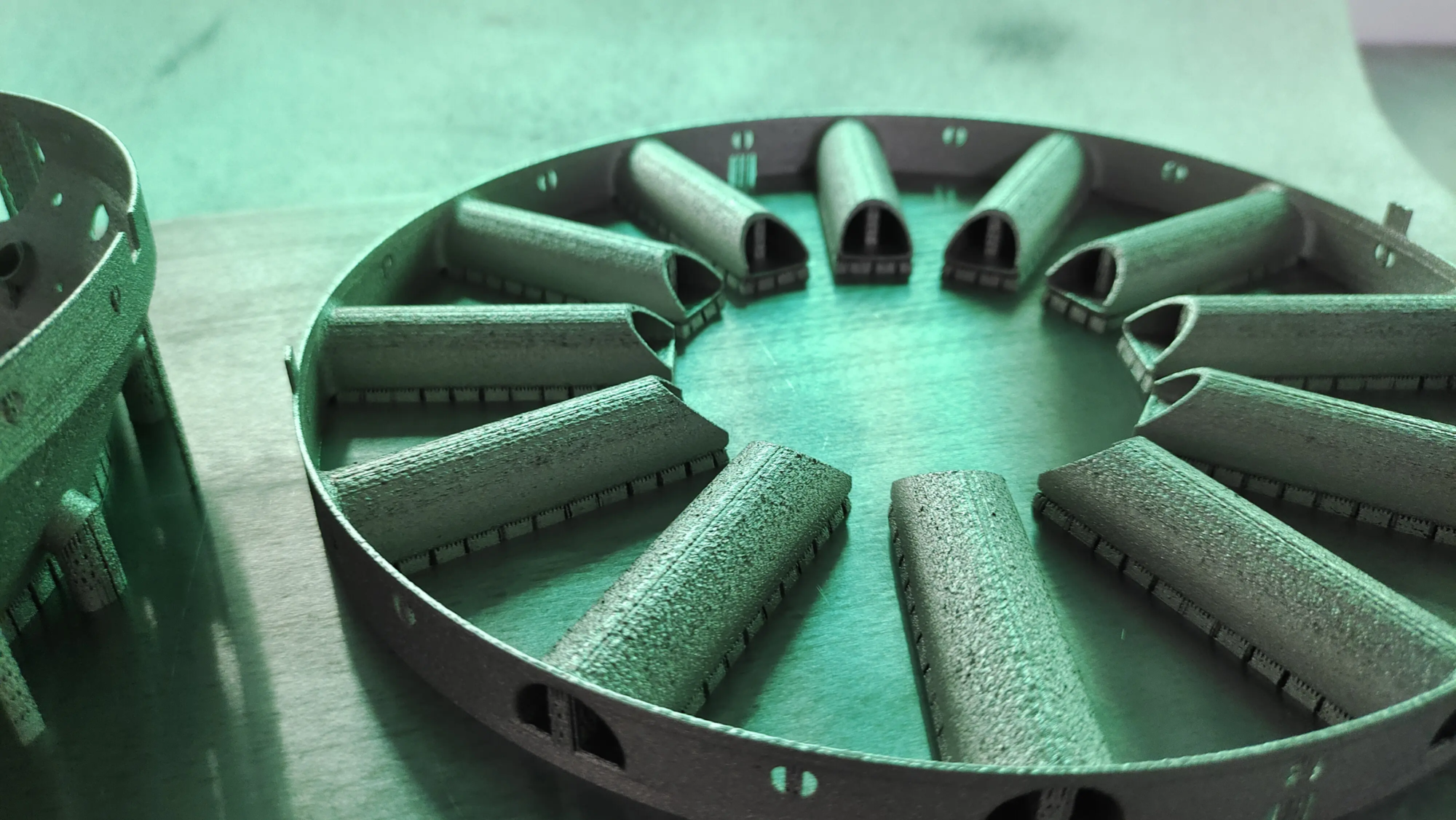

1. Aerospace and automotive parts

product: Turbine blades, fuel nozzles, lightweight brackets, custom piping.

Why they sell:

- Reduce weight: SLM printed titanium and aluminum parts can reduce fuel consumption by 15-20%.

- Performance: Complex internal channels (not possible with conventional machining) improve thermal management.

- Supply chain resilience: Producing used parts on demand eliminates inventory costs.

Great light edge: Our high-precision SLM printers achieve <20 micron accuracy for mission-critical components through comprehensive heat treatment and surface finishing.

2. Medical implants and devices

product: Spinal cages, dental crowns, patient-specific surgical guides.

Why they sell:

- Biocompatibility: 3D printed titanium and PEEK implants promote osseointegration.

- Personalization: Create anatomical matches (e.g. skull plates) from CT/MRI data.

- speed: Dental laboratories can create crowns within 24 hours, compared to the traditional 2 weeks.

Great light edge: We specialize in medical grade ISO 13485 processes including ultrasonic cleaning and passivation of implants.

3. Industrial tooling and fixtures

product: Injection molds, fixtures, composite layup tools.

Why they sell:

- Cost effectiveness: Compared with CNC processing molds, the cost is reduced by 60%.

- Conformal cooling: Mold inserts with optimized cooling channels can reduce cycle times by 40%.

- Durability: Tool steel molds can withstand >100k cycles.

Great light edge: We extend the life of our tools through vacuum heat treatment and EDM texturing.

4. Consumer electronics

product: Drone frames, wearable device cases, custom headphones.

Why they sell:

- Iterate quickly: Through in-house prototyping, product release speed is increased by 70%.

- aesthetics: Unique textures/geometry (e.g., lattice structures) enhance brand appeal.

- Sustainability: On-demand production reduces waste.

Great light edge: Multi-material functionality with hybrid parts combining polymer and metal.

5. Architecture and Design Elements

product: Scale models, custom lighting fixtures, art installations.

Why they sell:

- Design freedom: Organic geometries cannot be achieved by subtraction.

- Material type: From stainless steel to translucent resin.

- Complex assembly integration: Print an assembly of 100 parts as a single unit.

Great light edge: Large format printing + integrated post-processing for immediate display.

Conclusion: Beyond Prototyping – The Future is Additive

3D printing is no longer "only" for prototypes. As these best-selling products demonstrate, it’s solving real challenges: reducing aircraft weight, enabling personalized healthcare, and unlocking radical design economies. exist Gretel – China’s leading rapid prototyping manufacturer – We deploy SLM printers and multi-stage post-processing to transform complex ideas into practical reality. With capabilities ranging from titanium medical parts to automotive tools, plus One-stop organizing service (machining, polishing, coating), we deliver precision components with competitive delivery times.

Ready to transform your design? Customize your metal parts with GreatLight today – high quality, rigorously tested and shipped worldwide.

FAQ: Answers to your most important 3D printing questions

Q1: Can 3D printed metal parts compete with traditional manufacturing capabilities?

Absolutely. SLM’s titanium and Inconel parts are HIP (hot isostatic pressed) and GreatLight annealed to achieve density and mechanical properties comparable to forged parts.

Q2: How quickly can I receive the custom metal prototype?

With our expedited service, functional metal prototypes can be shipped to 5–7 daysincluding machining and surface treatment.

Q3: What file formats do you accept for production?

We support STEP, STL, OBJ and IGES files. For best results, please provide CAD files with wall thickness >0.8mm and clearly marked tolerances.

Q4: Are you responsible for post-processing?

Yes – ours "one stop shop" Services include CNC machining, sand blasting, powder coating, anodizing and heat treatment based on your functional requirements.

Q5: Are there any material restrictions for industrial applications?

We process more than 20 metals (aluminum, steel, titanium, copper alloys) and engineering polymers. Discuss operating conditions (temperature, stress, corrosion) with our engineers for material recommendations.

Q6: How to ensure the accuracy of parts?

Our SLM printers maintain a tolerance of ±0.025 mm and are verified by CMM inspection and 3D scans against CAD models.

Q7: Can you copy existing broken parts?

Yes. Through reverse engineering (3D scanning) and material matching, we can recreate legacy components without the need for original drawings.

10% off your first order, please mention code GLBLOG23.