The Frontier of Healthcare: Biocompatible Resin 3D Printed Medical Tools

The integration of additive manufacturing and medicine is revolutionizing patient care. While 3D printing using metal alloys such as titanium via selective laser melting (SLM) has enabled complex permanent implants, a quieter revolution is taking place in biocompatible resins. These specialty polymers are creating a new generation Medical tools that are customizable, precise and patient-specificincreasing efficiencies and improving outcomes across healthcare.

Understanding Biocompatible Resins: Beyond Standard Plastics

Not all 3D printing resins are created equal. Biocompatible resins are rigorously tested engineering polymers that comply with ISO 10993 (Biological Evaluation of Medical Devices) and USP Class VI standards. This means they have key features:

- Non-toxic and biocompatible: It is safe for temporary (usually limited-term) contact with human tissue, body fluids or blood and will not cause adverse reactions such as cytotoxicity or sensitization.

- Sterilization: Able to withstand common sterilization methods (autoclave, gamma radiation, ETO gas, Sterrad, chemical disinfectants) without significant deformation, loss of mechanical properties or leaching of harmful substances.

- Mechanical properties: Designed to achieve the specific strength, stiffness, flexibility and durability properties required for their intended medical application, often mimicking bone or soft tissue.

Common classifications based on duration/type of contact include Class I (surface device, short-term), Class II (external communication, extended), and Class III (implantable, extended/permanent – although resin is generally reserved for temporary implants/surgical tools). Materials range from durable, rigid resins that mimic bone to flexible, tough resins that are suitable for soft tissue contact.

Transformative applications in medical tools

Biocompatible resin 3D printing excels at creating customized devices where speed and precision are critical:

- Surgical Guidelines and Templates: Perhaps the most mature application. Patient-specific guides for dental implants, spine surgery, craniofacial reconstruction, and orthopedic surgery fully conform to unique anatomy, greatly improving surgical accuracy, reducing operative time, and minimizing tissue trauma.

- Diagnostic and laboratory tools: Custom trays for impressions, bite splints for TMJ treatment, dental models, hearing aid housings, microfluidic devices for diagnostics, and anatomical models for preoperative planning and education.

- Temporary prostheses and orthotics: Custom finger splints, limb socket liners, temporary crowns/bridges, and assistive device jigs are custom-fitted to the patient’s morphology to enhance comfort and function during the transition period prior to a permanent solution.

- Drug Delivery Devices: Prototypes and some end-use components for inhalers, dispensers or transdermal patches requiring biocompatible contact surfaces.

- Minimally invasive instruments: Prototyping and low-volume production of specialized handles, non-cutting components of endoscopic tools, or custom nozzle tips to achieve ergonomics tailored to specific procedures.

Key advantages over traditional manufacturing

- Unparalleled customization: Truly patient-specific devices utilizing DICOM data (CT/MRI scans) can be produced quickly and cost-effectively in a way that is not possible with traditional molding or machining at this scale. This greatly improves fit, functionality and patient comfort.

- Rapid prototyping and iteration: Designs can be perfected overnight. Surgical teams can evaluate and adjust guides or instruments based on the latest scans within days, accelerating innovation and optimizing patient-specific solutions.

- Complex geometric shapes: Complex internal channels for fluids, lattice structures for lightweight strength, or fully anatomical organic shapes can all be fabricated as easily as simple blocks.

- Reduce lead times and costs (for custom/variable parts): Eliminate expensive tooling (moulds, jigs) required for low-volume custom products. Digital inventory replaces physical storage.

- Enhanced performance: Improved surgical accuracy reduces complications and shortens recovery time. Better-fitting equipment can improve patient compliance and treatment outcomes.

Addressing challenges and standards

Success requires strict compliance with regulations and a deep understanding of material limitations:

- Regulatory Compliance: Obtaining support from the FDA (US), CE Mark (EU) or other regional regulatory pathways requires documented material certification (ISO 10993 test reports), validated printing/post-processing workflows, and rigorous quality control. Manufacturers must demonstrate traceability.

- Purpose of material selection: choose correct Biocompatible resins are critical. Factors include duration of contact/intimacy, required sterilant compatibility, necessary mechanical properties (impact resistance, flexibility, tensile strength), potential imaging needs (radiolucency), and hydrolytic stability.

- Process verification: Ensuring that every printed part (regardless of batch) meets specifications requires validated printing parameters, calibrated equipment, a controlled environment (temperature, humidity) and qualified operators.

- Powerful post-processing: Thorough cleaning to remove toxic uncured resin residue cannot be ignored. Support removal must be done with care to avoid damaging delicate features. Secondary curing (post-cure) is critical to obtain optimal biocompatibility and mechanical properties. Depending on the application, surface treatment (smoothing, sealing) may be required.

- Limited lifespan: Although suitable for temporary tools and guides, most biocompatible resins (unlike metallic implants) degrade over time under physiological stress and are not suitable for permanent implantation.

GreatLight: Your partner in advanced medical manufacturing

Harnessing the power of 3D printing with biocompatible resins requires the expertise of a partner. GreatLight integrates cutting-edge technology and deep manufacturing expertise:

- Materials expertise: We use our knowledge of material properties and regulatory pathways to guide customers in selecting the best biocompatible resin for their specific medical tool application. We offer printing on certified Class I and Class II biocompatible resins.

- Precision printing: Utilizing advanced stereolithography (SLA) and digital light processing (DLP) technologies, it is possible to provide micron-level resolution for complex medical devices.

- Unparalleled post-processing: Essential for biocompatibility. Our rigorous protocols ensure thorough cleaning, precise support removal, controlled post-cure, and biomedical-grade surface finishing tailored to the resin and application.

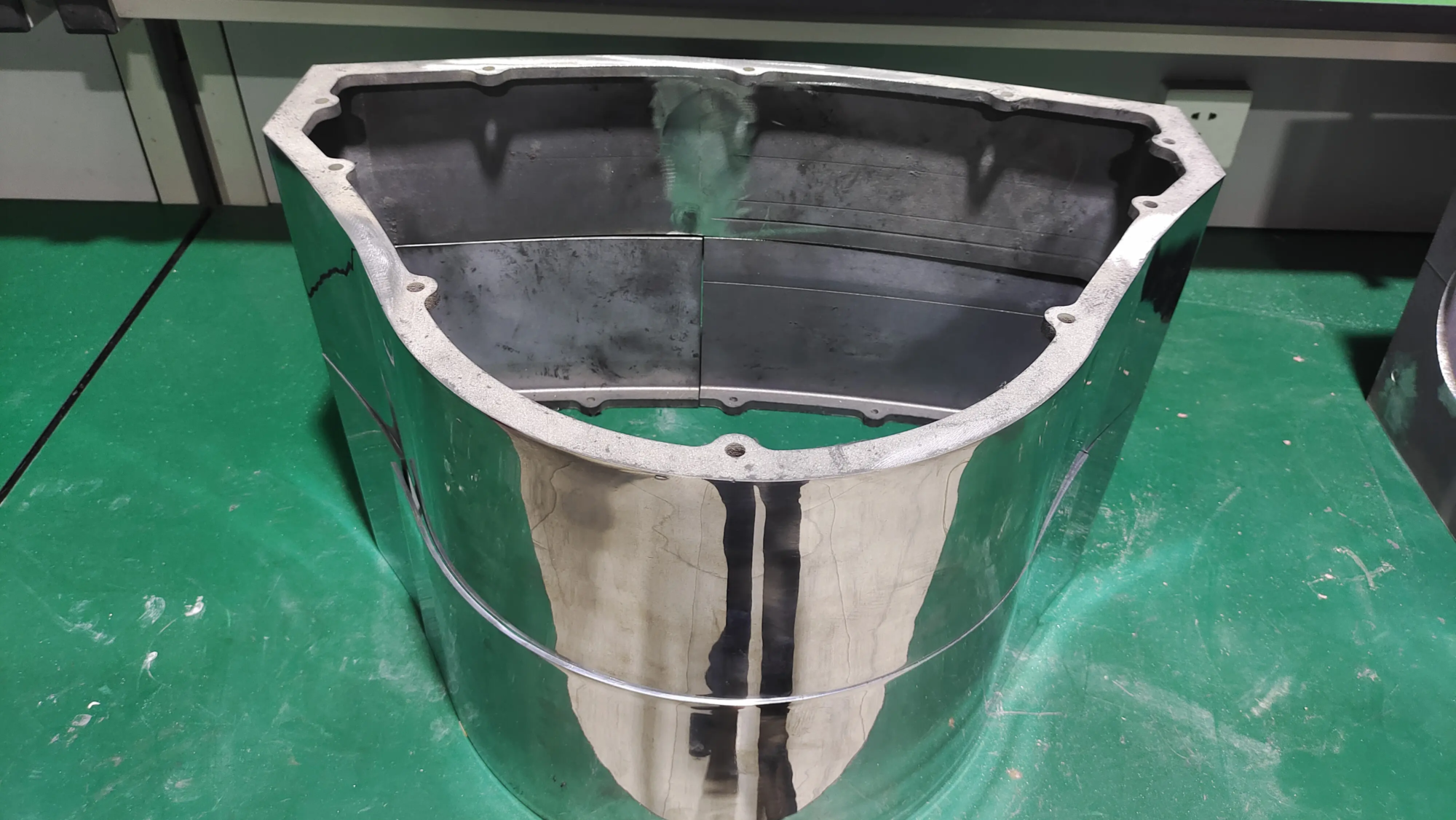

- Complementary metal solutions: For applications requiring permanent metal implants (using SLM), complex sterile instrument components or housings, our expertise in metal laser sintering (SLM/DMLS) seamlessly complements our biocompatible resin capabilities.

- End-to-end service: From design optimization support (especially DfAM – Design for Additive Manufacturing), selecting the right materials and processes, to precision printing, rigorous post-processing and comprehensive finishing (optional sterile packaging), GreatLight provides a trustworthy one-stop solution.

- Speed and agility: The ability to rapidly prototype and transition to production can accelerate development cycles and deliver critical medical tools faster.

At GreatLight, we understand the critical nature of medical devices. our commitment Quality, precision and regulatory compliance Making us a reliable partner in taking innovative biocompatible resin 3D printed medical tools from concept to clinically reliable reality.

in conclusion

Biocompatible resin 3D printing is more than just a novelty for prototyping. This is a powerful manufacturing technology that enables new models of patient care. From dramatically improving surgical accuracy with custom guides to creating unique temporary prostheses, the impact on efficiency, cost-effectiveness, and patient outcomes is profound. As materials science advances and regulatory frameworks mature, we expect wider applications. Working with expert manufacturers like GreatLight to address the complexities of biocompatible printing, sterilization and compliance is critical for healthcare innovators looking to capitalize on this transformative technology. Today, the future of personalized medicine is printing biocompatible layers with precision, layer by layer.

FAQ: Biocompatible Resin 3D Printed Medical Tools

Q1: Are biocompatible resin 3D printed parts safe for use on or in the body?

A1: Yes, when printing Specially certified biocompatible resin and use handle Proven protocol (thoroughly cleaned and post-cured), these parts meet strict safety standards (such as ISO 10993 and USP Class VI) for the duration and type of expected exposure. Be sure to verify the manufacturer’s specific resin certifications and processing capabilities.

Q2: How to sterilize biocompatible resin parts?

A2: Common methods include ethylene oxide (ETO) gas, gamma radiation, steam autoclaving, hydrogen peroxide plasma (Sterrad), and chemical sterilization. Crucially, the selection of biocompatible resin must Compatible with intended sterilization method. Manufacturers should verify the performance of selected resins after sterilization.

Q3: Can biocompatible resin be used for permanent implants?

A3: Generally speaking, No. Current biocompatible resins are primarily designed and approved for casual contact (minutes to months) or limited-term implantation (usually up to 30 days). Permanent implants typically require metal alloys (such as titanium printed via SLM) or highly specialized, rigorously tested polymers that comply with long-term implant Class III regulations.

Q4: What are the main advantages of 3D printed medical tools over traditional manufacturing?

A4: The main advantages include: Unparalleled customization (patient specific), faster turnaround (especially prototypes and small batches), Cost effective For custom parts (no tools), the ability to create complex geometric shapes Machining/molding is not possible, and Rapid design iteration.

Question 5: What certifications should I look for from manufacturers of biocompatible resin medical parts?

A5: Priority will be given to manufacturers with the following characteristics:

- expertise ISO 10993 Nuances of Biocompatibility Testing.

- ability Verify sterilization Print parts.

- Comply with quality management systems (e.g. ISO 13485 Specifically for medical devices).

- Strict process control and Material traceability.

- understand FDA/CE Regulatory Pathway Used in medical devices. Require written certification and standard operating procedures.

Q6: Is Ferrite responsible for the entire process from design to finished medical tool?

A6: Yes, Glow specializes in End-to-end solution. We provide expertise in design consulting (DfAM), material selection, precision SLA/DLP printing using certified biocompatible resins, critical post-processing (cleaning, curing, surface finishing) and have complementary SLM metal printing capabilities. We handle everything under strict quality control protocols suitable for medical applications.