Leveraging Innovation: Breakthrough Advances in BLT 3D Printing

The field of additive manufacturing (AM), especially metal 3D printing, is experiencing a renaissance. At the forefront of this development is precision laser powder bed fusion (PBF-LB/SLM/DMLS) technology, with companies such as Xi’an Guangming Laser Technology Co., Ltd. (BLT) continuing to push the boundaries of what is possible. Understanding these breakthroughs is critical for industries that require high-performance metal parts (aerospace, medical, energy, automotive). At GreatLight, as experts in utilizing cutting-edge SLM equipment and technology, we see every day how BLT’s innovations translate into tangible benefits for rapid prototyping and production.

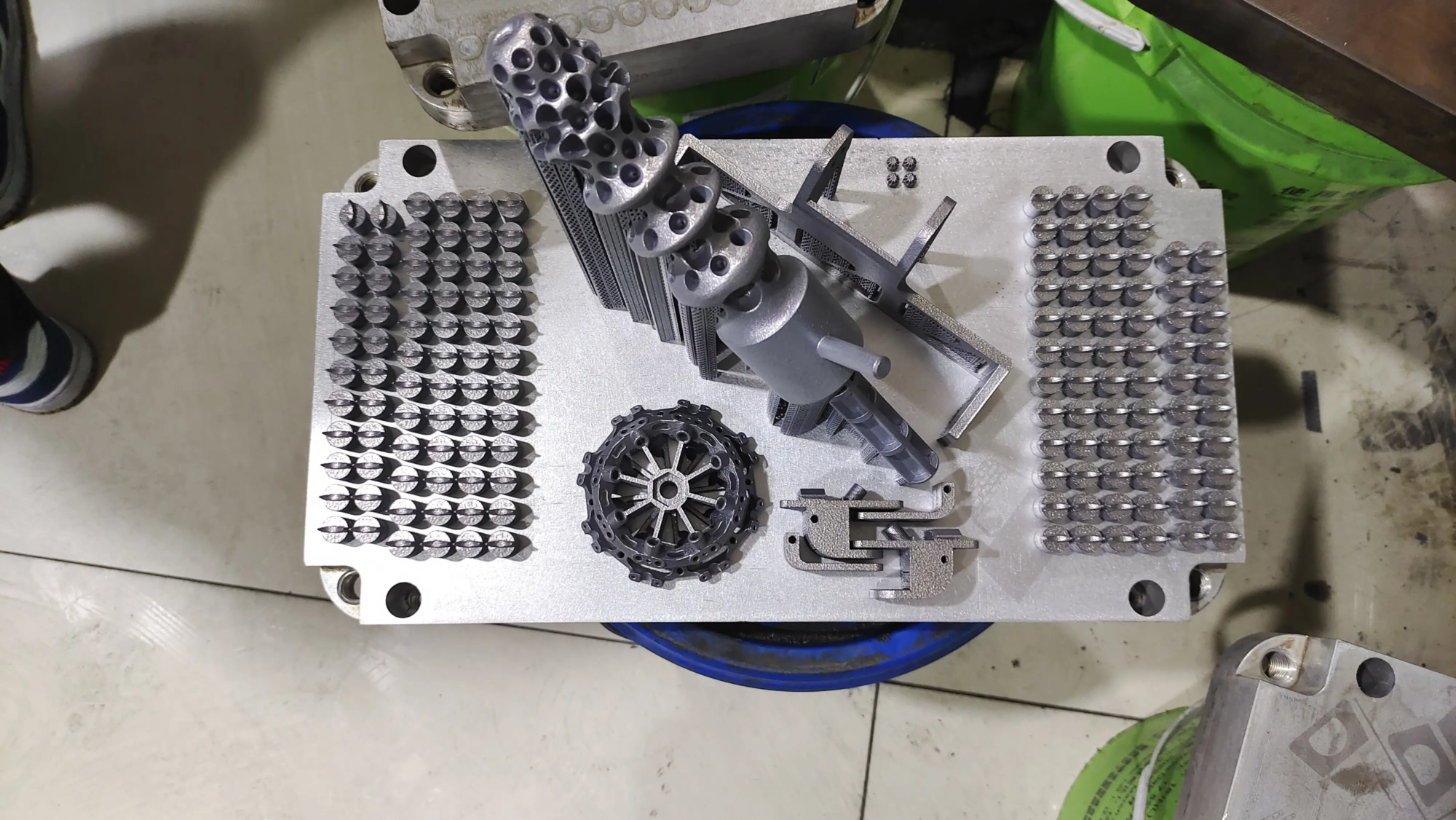

Beyond incremental gains: Key breakthroughs in BLT 3D printing

BLT’s engineers have gone beyond mere improvements to make significant leaps in metal additive manufacturing:

-

Unprecedented printing speed and productivity: One of the most critical barriers to metal additive manufacturing is production speed. BLT has made significant advances in this area, developing multi-laser systems that operate in highly coordinated modes. Imagine a system with 8, 12 or even more 500W-1000W fiber lasers scanning simultaneously. It’s not just about raw laser counts; Its advanced beam modulation, optimized scanning strategy and coating machine advancements ensure reliability in high-speed operation. The result can be Increase productivity by 200% or more Lead times and cost per part are significantly reduced compared to older single-laser systems – a game-changer when it comes to turning prototypes into viable series production.

-

Challenging Size Limitations: Mastering Large Format Printing: Continuously manufacturing large, complex metal parts used to be a major challenge. BLT excels at scaling up PBF technology while maintaining precision and material integrity. Their large machines have a build volume of over 500mm x 500mm x 1000mm and are capable of producing critical aerospace components, turbine casings or industrial tools in a single build. This eliminates assembly steps, reduces potential points of failure, and unlocks designs previously thought to be traditionally unmanufacturable.

-

Developments in materials science: opening up new alloy fields: BLT is not just an innovation machine; They are expanding their material palette. They are leading the way in developing and qualifying new metal powders optimized specifically for their laser platforms. This goes beyond the common titanium (Ti-6Al-4V), aluminum (AlSi10Mg/Sc), stainless steel (316L, 17-4PH) and Inconel (625, 718). They have made significant progress in:

- Copper alloy: Overcome reflectivity challenges and enable printing of pure copper and copper alloys (e.g. GRCop, CuCrZr) for unparalleled thermal management in electronics and rocketry.

- High-strength aluminum scandium (Scalmalloy®): Offers the same strength as titanium at a lighter weight for aerospace and high-performance applications.

- High temperature alloy: Advanced nickel superalloys and refractory metals for extreme environments.

- Reactive materials: Implement safe and controlled processes for reactive alloys such as titanium aluminide (TiAl) or magnesium.

BLT’s deep library of process parameters ensures optimal density, mechanical properties (exceeding castings, approaching forgings) and surface quality for these materials.

-

Smart software, process monitoring and automation: The real breakthrough lies in synergy. BLT integrates advanced software that uses AI-driven algorithms to optimize part orientation, support generation and laser scanning paths to minimize stress, deformation and build time. Crucially, they combine Multi-sensor process monitoring system. These systems typically use high-resolution cameras and optical sensors to detect anomalies such as spatter, lack of fusion, or recoater issues real time. This allows for potential process interruptions or adjustments, significantly improving first-time pass rates and reducing the burden of costly failed builds and post-build inspections.

- Improve surface quality and reduce post-processing: BLT provides a comprehensive focus on the entire workflow. Innovations in precise beam shaping, finer powder layers (down to 20μm) and optimized parameter sets directly contribute to significantly improved print surface finishes. While some post-processing is still necessary for many applications, the starting point is extremely superior. This means reduced machining allowances, shorter CNC times, less material waste in finishing and cost savings.

Transforming Industries: Unleashing Applications

These breakthroughs are not theoretical. They enable practical, high-impact applications:

- aerospace: Lightweight, topology-optimized structural components, complex fuel nozzles, heat exchangers, turbine blades (including scramjet components), and satellite components—often can be manufactured faster and perform better than conventional methods.

- Medical: Rapidly manufacture patient-specific implants (cranial, spinal, orthopedic) with complex porous structures for osseointegration, biocompatible surgical guides and instruments.

- vitality: Efficient heat exchangers, complex combustion chambers for power generation and rockets, corrosion-resistant components for oil and gas.

- car: Lightweight breakthroughs in battery components for motorsport and electric vehicles, durable jigs/fixtures for assembly lines, rapid prototyping of complex intake manifolds or powertrain parts.

- Industrial Tools: Conformal cooling inserts for injection molds significantly reduce cycle times, and robust tooling jigs and fixtures enable rapid production.

GreatLight: Your partner for leveraging BLT technology

At GreatLight, we know that realizing the full potential of advanced BLT 3D printers requires more than just the machine. It requires deep process expertise, meticulous parameter optimization and seamless post-processing integration. This is where our specialization highlights:

- Advanced SLM solutions: We use state-of-the-art SLM (Selective Laser Melting) technology, leveraging the core principles that BLT excels at – multi-laser efficiency, large-scale capabilities and robustness.

- Material mastery: We work with a variety of metal alloys—from common titanium, aluminum, stainless steel, and Inconel to challenging copper and specialty alloys—customizing processes for optimal strength, density, and surface properties.

- End-to-end service: we truly offer One stop solution:

- Expert consultation: Consulting on DfAM (Design for Additive Manufacturing) to maximize part performance and cost-effectiveness.

- Precision printing: Reliably execute complex builds on an industrial-grade SLM platform.

- Comprehensive post-processing: One-stop provider of CNC machining, heat treatment (stress relief, HIP), surface treatment (sandblasting, polishing, painting, coating, electroplating). This ensures unparalleled quality control and streamlines your supply chain.

- Rapid prototyping and more: We specialize in solving complex metal rapid prototyping challenges and accelerating your development cycle. Our scale allows us to easily transition to low to mid-volume production with exceptional quality consistency.

- Commitment to excellence: As one of China’s premier rapid prototyping partners, we combine technology investments with unwavering quality standards and rigorous industry certifications.

in conclusion

The breakthroughs pioneered by BLT in metal 3D printing represent a paradigm shift. They address the core limitations that once hindered mainstream production of the technology – speed, size, material variety and reliability. Multi-laser efficiency, large-scale construction, novel material functionality, intelligent process control and improved surface quality are no longer concepts of the future but an established reality that will change the design and manufacturing paradigms of key industries.

For innovators and engineers who push boundaries, working with an expert service provider like GreatLight is critical. Our mastery of SLM technology, combined with deep materials knowledge and comprehensive in-house post-processing, ensures you take full advantage of these advancements. We turn complex ideas into precision metal parts faster, more efficiently and more cost-effectively than ever before. There’s no denying that the future of metal manufacturing is additive manufacturing, and BLT’s breakthroughs through expert partners are leading the way.

FAQ: Answers to your BLT 3D printing questions

Q1: What types of metal materials can be printed with BLT/SLM technology?

A1: BLT/SLM technology supports a variety of materials, including titanium alloys (Ti64, TiAl), aluminum alloys (AlSi10Mg, Scalmalloy®), stainless steel (316L, 17-4PH, 15-5PH, maraging steel), nickel superalloys (Inconel 625, 718, Hastelloy), high copper alloys (pure copper, GRCop, CuCrZr), cobalt-chromium alloys and precious metals. GreatLight provides the expertise to select and process the best materials for your specific application.

Q2: How fast is BLT metal 3D printing compared to traditional methods?

A2: While design complexity affects comparisons, BLT’s multi-laser technology significantly speeds up builds and can often complete complex parts Soon a few days or even weeks Superior to CNC machining, especially for complex geometries. For functional prototypes and complex end-use parts that require no assembly, the lead time advantage is huge. SLM is often the best choice for complex geometries that cannot be achieved with traditional machining only Viable production methods.

Question 3: What is the surface finish of the surface printed directly from the printer? What organization options does GreatLight offer?

A3: The printed surface exhibits characteristic layered roughness. However, BLT’s optimized parameters produced better initial results than the old system. GreatLight offers comprehensive post-processing: tight tolerance CNC machining (±0.05mm achievable), bead/shot blasting, electropolishing, chemical polishing, hand polishing/vapor polishing (for plastics), anodizing, painting, powder coating, electroplating (chromium, nickel, nickel phosphorus) and advanced heat treatments such as hot isostatic pressing (HIP).

Question 4: Are parts made with BLT/SLM technology strong enough for end-use applications?

A4: Of course. When printed and post-processed correctly, SLM parts can often meet or exceed the performance of cast equivalents, and can approach forged performance, especially after HIP processing. Mechanical properties (tensile, yield strength, fatigue) and material density (>99.5%) are strictly controlled and tested to meet industry standards (ASTM, ISO, AMS). Provide certification documentation.

Q5: Why choose GreatLight for my metal prototypes or production parts?

A5: GreatLight offers a unique combination of:

- Expert technology: Use an advanced multi-laser SLM system with BLT-inspired innovation.

- Breadth and depth of material: Specializing in processing various engineering alloys.

- True one-stop service: Handling DfAM, printing, heat treating, CNC machining and all surface finishing in-house – ensuring quality control and faster turnaround.

- Excellent rapid prototyping: Specialized in solving complex, rapid metal prototyping challenges.

- Cost effectiveness: Leverage scale and efficiency to offer competitive pricing for custom parts.

- Quality Commitment: Comply with the strict standards of the aerospace, medical and high performance industries.

Q6: Compared with other processes, what are the main advantages of choosing BLT-type metal additive manufacturing?

A6: The main advantages include:

- Complexity degrees of freedom: Produce geometries not possible with machining (internal channels, lattices, conformal cooling, organic shapes).

- Lightweight: Optimize the design (topology optimization) to reduce weight without sacrificing strength.

- Partial merge: Combine components into a single part, increasing reliability and reducing assembly time/cost.

- Iterate quickly: Faster design-to-prototype cycles.

- custom made: Economically produce custom/low-volume parts.

- Material efficiency: Near net shape production minimizes waste compared to subtractive methods.

Ready to harness the power of advanced metal 3D printing? Contact GreatLight today to discuss your project and find out how our expertise and one-stop service can turn your most complex metal part ideas into reality faster and more efficiently.